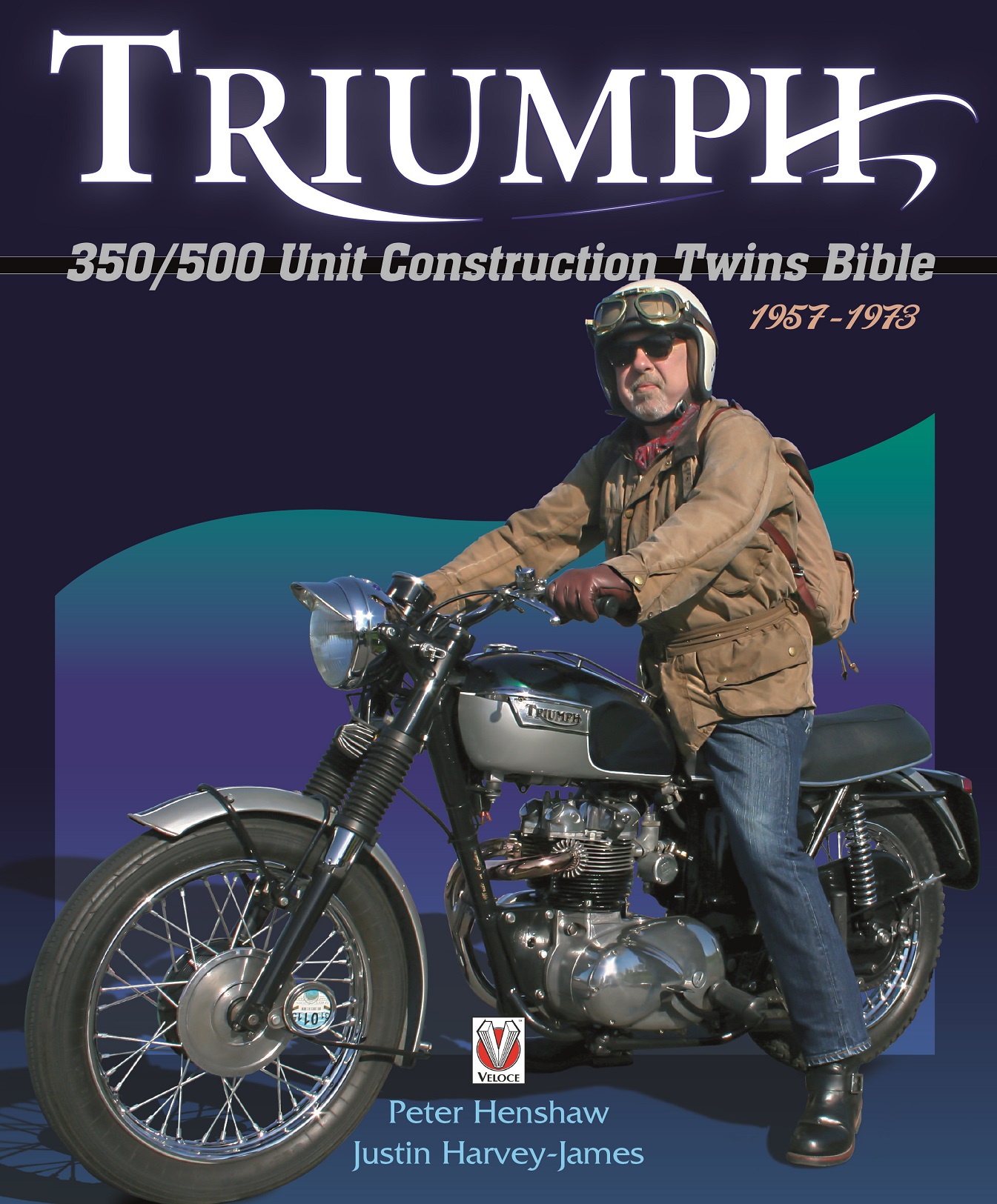

The Triumph ‘C’ Range Machines 1957-1974

This Site is designed to assist Buyers, Owners and Restorers in confirming the Specification for the Triumph 350cc and 500cc Machines.

It covers all models such as the Triumph T21, 3TA, 5TA, Tiger 90, Tiger 100 and the Competition, Police and Military Versions.

You will find detailed information on each model for each year together with sections on Dating, Colour Schemes and Parts.

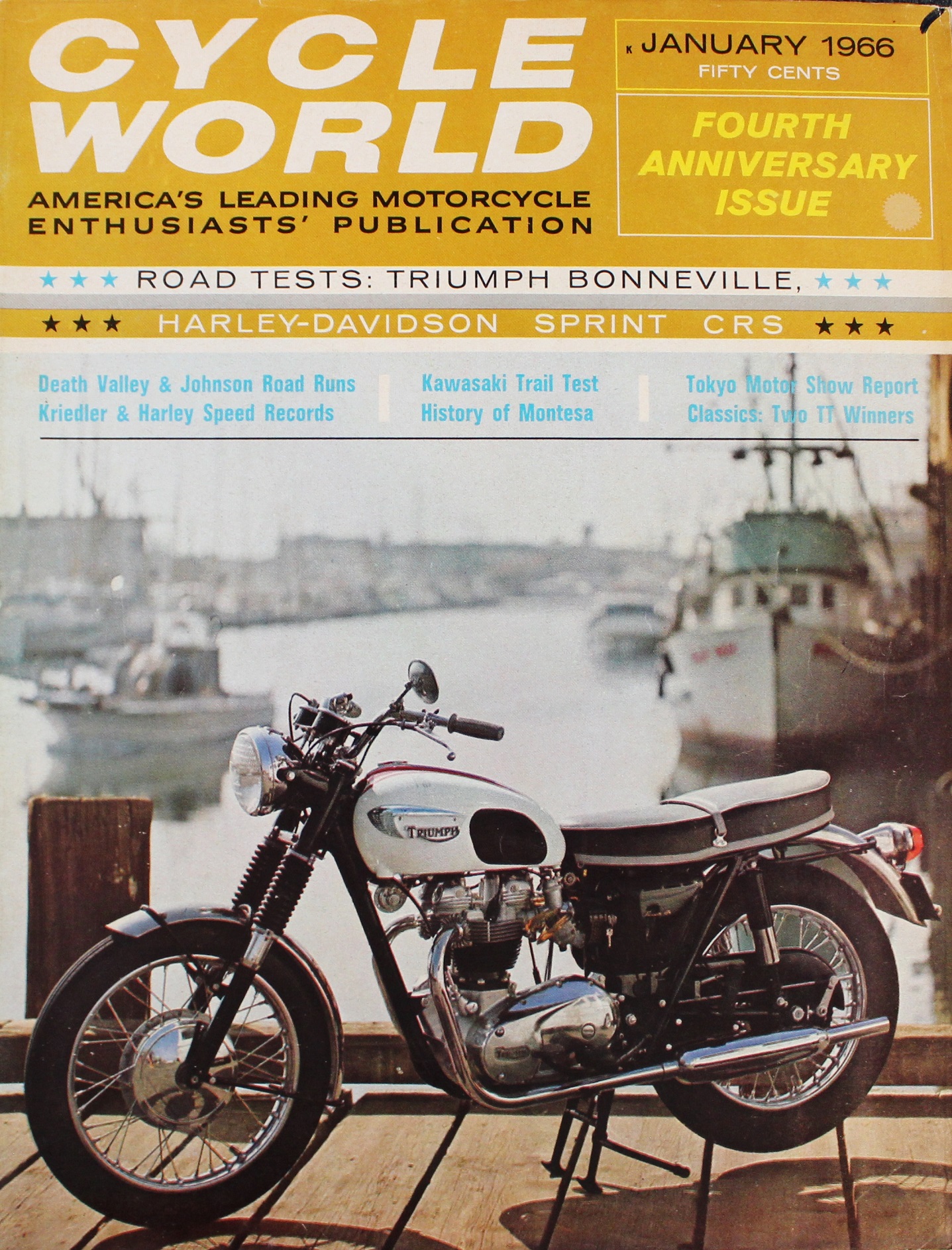

Additionally there are pages on Triumph History, The Factory Records, Magazine Road Tests and The Works Manual.

To view many of the Triumph Parts books use this link to Classic British Spares www.classicbritishspares.com and use their Parts Book library Tab.

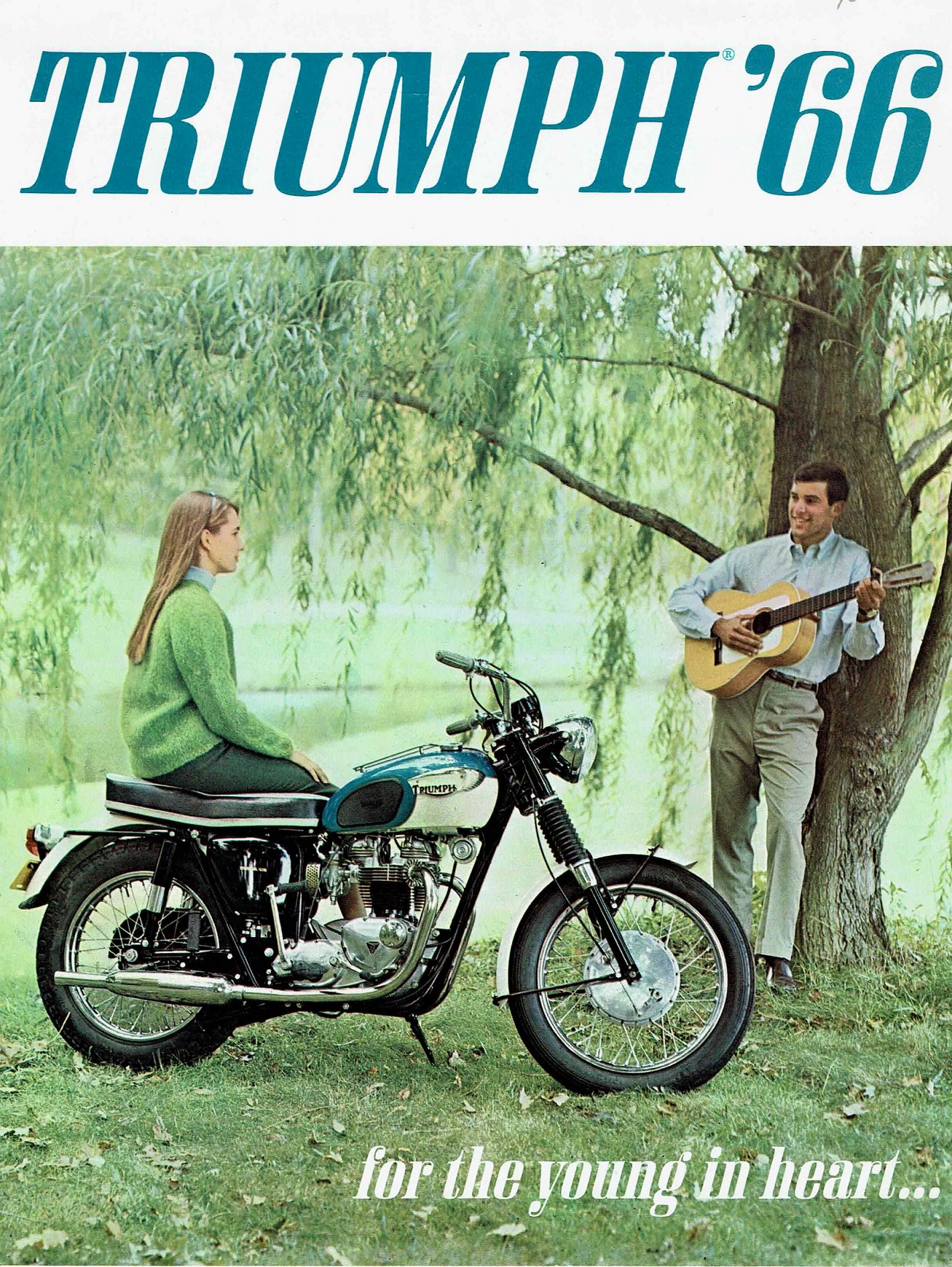

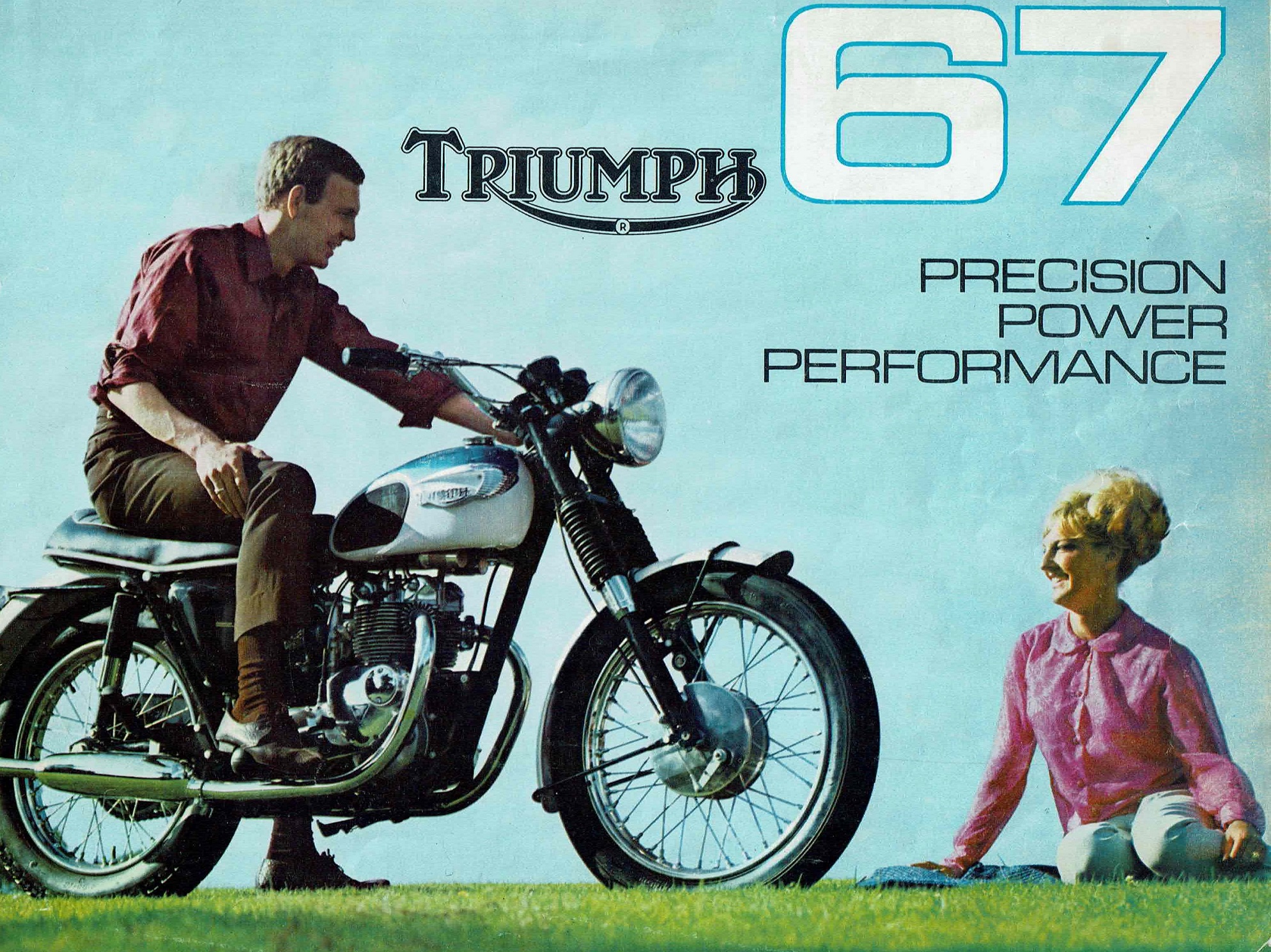

To view the Brochures use this link to Classic Bike Biz http://classicbike.biz/ where you will find the Triumph Brochures and other material.

Added to the site are additional photographs from the VMCC Library Collection

Many of which have not been previously published.

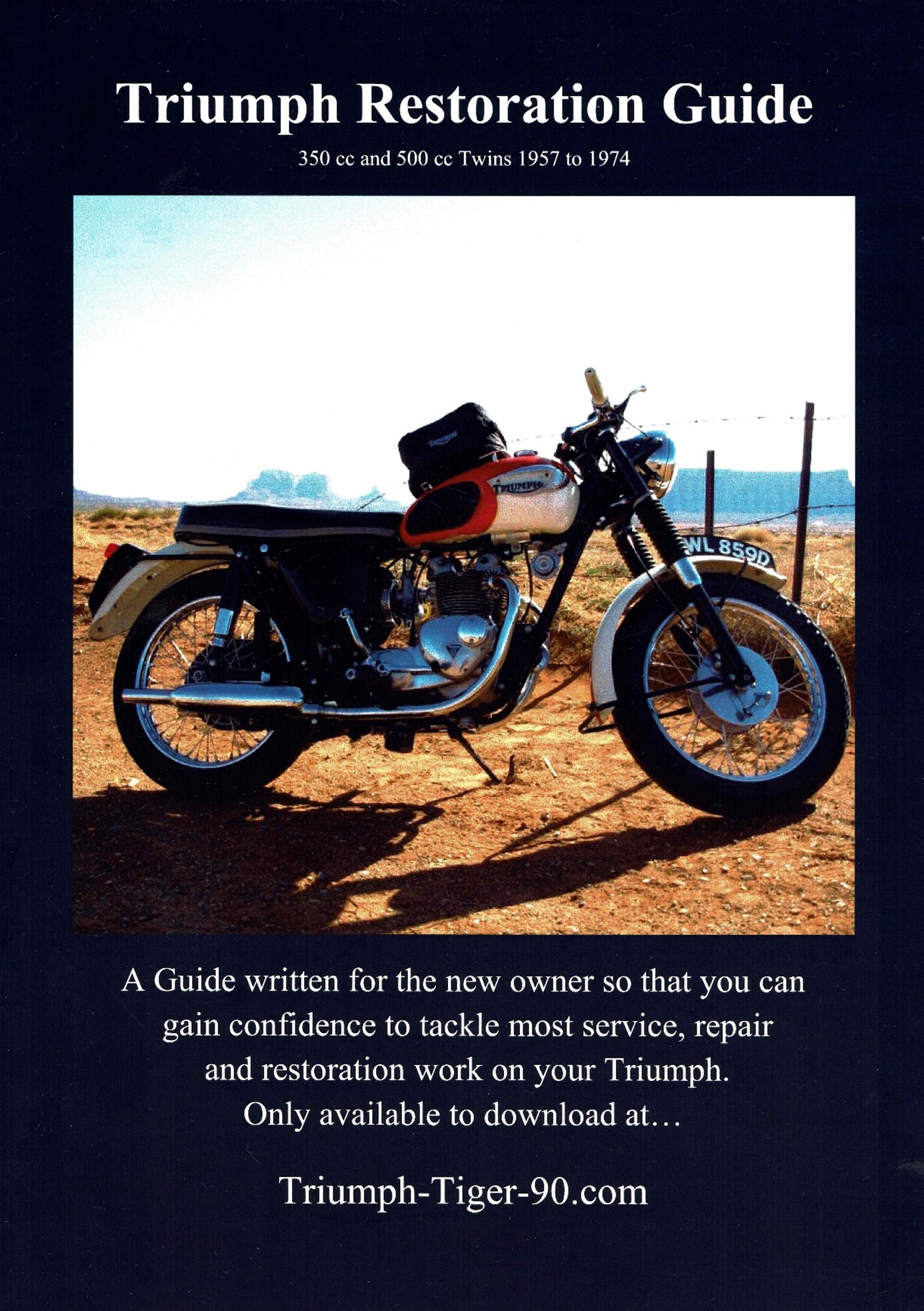

The Restoration Guide available to download here.

The C Range Triumphs are rewarding to ride, easy to maintain and make ideal first Classic’s for new owners.

Do not be put off by the perceived complexity of maintenance or restoration as most parts are available

and the skills needed are within the capability of any confident owner with the appropriate tools.

A simple parts book to help the new owner has been added, use the Parts Book Tab.

When working on any Meriden Triumph I recommend obtaining a copy of the Parts Book for the year.

The Owner’s Manual if available for early machines, and a copy of the Brochure for the Model Year.

The Specifications Sheets, Supplementary Parts Lists, Road Tests and Appropriate Factory Bulletins are useful if you are seeking to create an accurate restoration while the Works Manual is invaluable for new owners, mechanics and engineers, a scanned copy can be found using the Manual tab.

From my work with the Factory Records and interviews with former dealers, employees, Triumph experts and owners together with studying surviving original machines and photographs, I have come to the conclusion that many machines especially for the export market were built and sold in specifications that differ from the published brochures.

In addition, specifications were constantly changed as new models and parts were introduced during production.

On this site and others you will find the parts books, repair manuals, brochures, catalogues, images and all the Information and support you need to succeed with your restoration, whether you are a first timer or an expert.

For those who are already experienced owners I hope that you find my information interesting and useful.

Justin Harvey-James

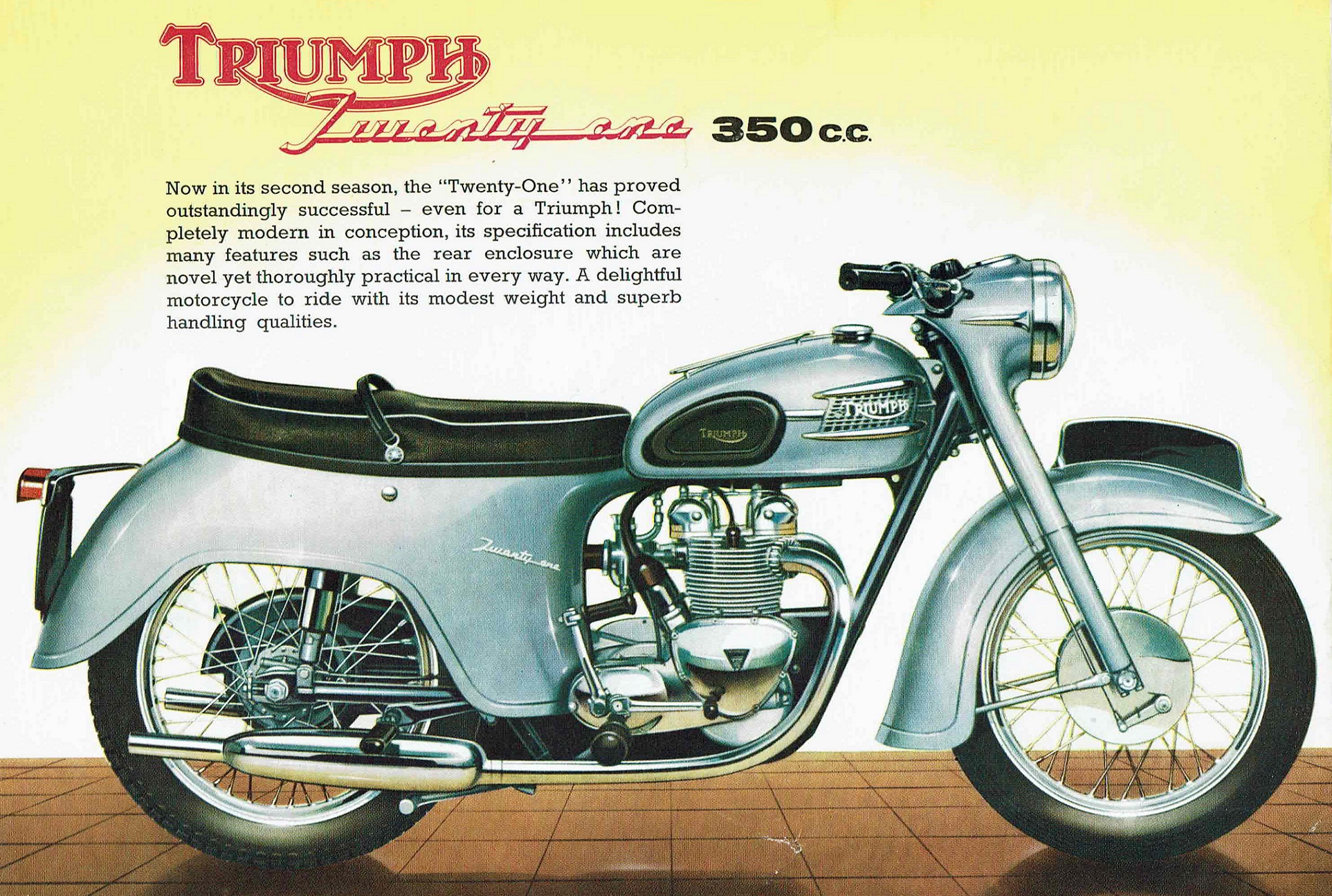

Motorcycling Feb 25th 1957 Press Release of the new T21 model.

1957

Models Covered

1957 Triumph T21 760 Machines

Sales for all Models for 1957

| 1957 | T15 | T20 | T20C | T21 | 5T | T100 | TR5 | TRW | 6T | TR6 | T110 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Home | 1 | 3960 | 571 | 244 | 618 | 495 | 47 | 1028 | 42 | 729 | |

| Export | 31 | 3011 | 1167 | 294 | 608 | 686 | 88 | 2099 | 1620 | 1571 | 1872 |

| Other | |||||||||||

| 32 | 6971 | 1738 | 538 | 1226 | 1181 | 135 | 2100 | 2648 | 1613 | 2601 |

The sales figures for the T21 here give an inaccurate picture as all of the machines built are dispatched from the factory by September 1957 to locations across the world.

The start of production for the next model year begins usually in late August after the factory shutdown so that new models are ready for the Earls Court Show and batches of machines are then built for the important export markets.

The ‘C’ range machines share parts and design features with other models in the Triumph Range and earlier parts show similar shapes and manufacturing methods.

The patent numbers you will find on the triangular plate on the timing cover and in period brochures refer to several Triumph features by now standard across the range.

Total production of the unit range between the start of production in 1957 with H1 to the last machine (T100T JJ 58013) in 1974 is a little over 100,000 machines.

A word of warning… On all Triumphs you will find a bewildering array of fasteners and threads (Nuts and Bolts). The majority of fasteners and threads are to British Standards, BSCY (Cycle) or BSF. Threads into alloy such as crankcases vary and depend on the design requirements and you will find engine studs in course (BSF) thread at one end and BSCY at the other. The parts books usually provide the length of studs and bolts but no hint as to the diameter, thread form, finish or head type. To identify bolt and stud diameters refer to the parts book and use the associated washers to indicate the bolt diameter. For example part number S25-2 is a 3/8 diameter plain washer while S25-3 is 5/16 Plain washer. Nuts come in a variety of types including plain, chamfered, reduced, thinned and locking, and prior to the now common Nyloc nuts, Philidas, Simmonds and later Clevlock nuts were used in certain critical locations. The parts book illustrations hint at the type of fastener used and general assembly but from my experience these illustrations cannot be trusted and only by studying original machines and photographs from the period will you find the answers.

For owners new to Triumphs and in general to older motorcycles it is essential that you familiarise yourself, with the forms of fasteners, thread patterns and tools appropriate for your machine. Prior to 1967 all fasteners and thread forms used by Triumph were to British Standards (though bearings were often Metric). Essentials for your tool kit should include AF and Whitworth Spanners and Sockets, a Torque Wrench, Taps and Dies in BSF, BSP, BSCY (Cycle) and for later machines UNF, a micrometre and thread gauge. I am slowly identifying the specific threads and fasteners used by Triumph and in the sections below I have included this information where it is needed.

A useful booklet to look for is Fowlers Mechanics’ and Machinists’ Pocket Book, published for many years and packed with information, hints and tips and an essential for your workshop. More advanced restorers will usually aspire to have a bike lift, engineers vice, a lathe, milling machine, press, blast cleaning cabinet, compressor, plating kit, spray equipment and stocks of spares but all of these are not essential to restore your Triumph to a good standard.

Specific Triumph workshop tools for certain tasks are available or can be made and are detailed in the works manual, a copy of which you will find on this site.

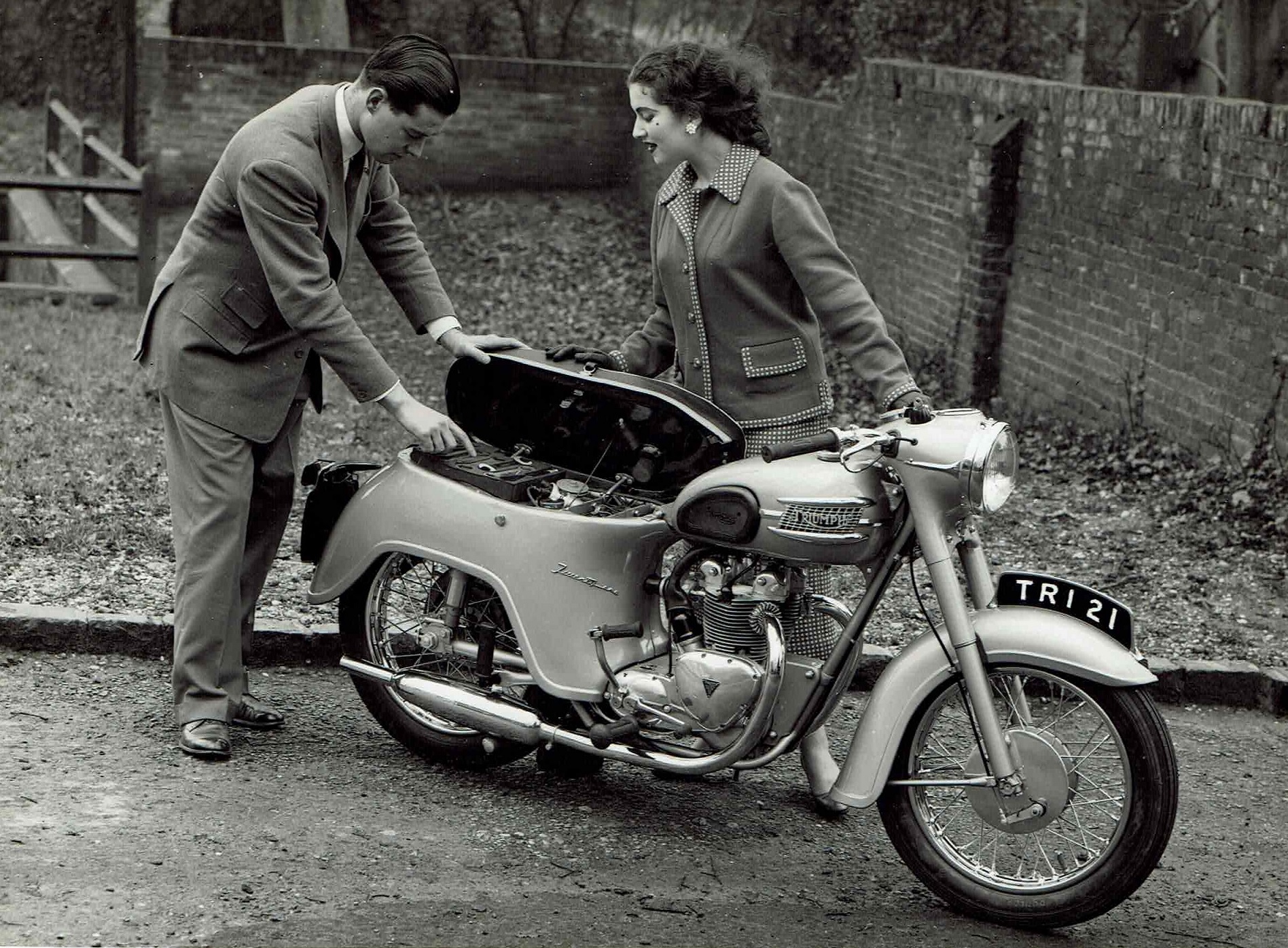

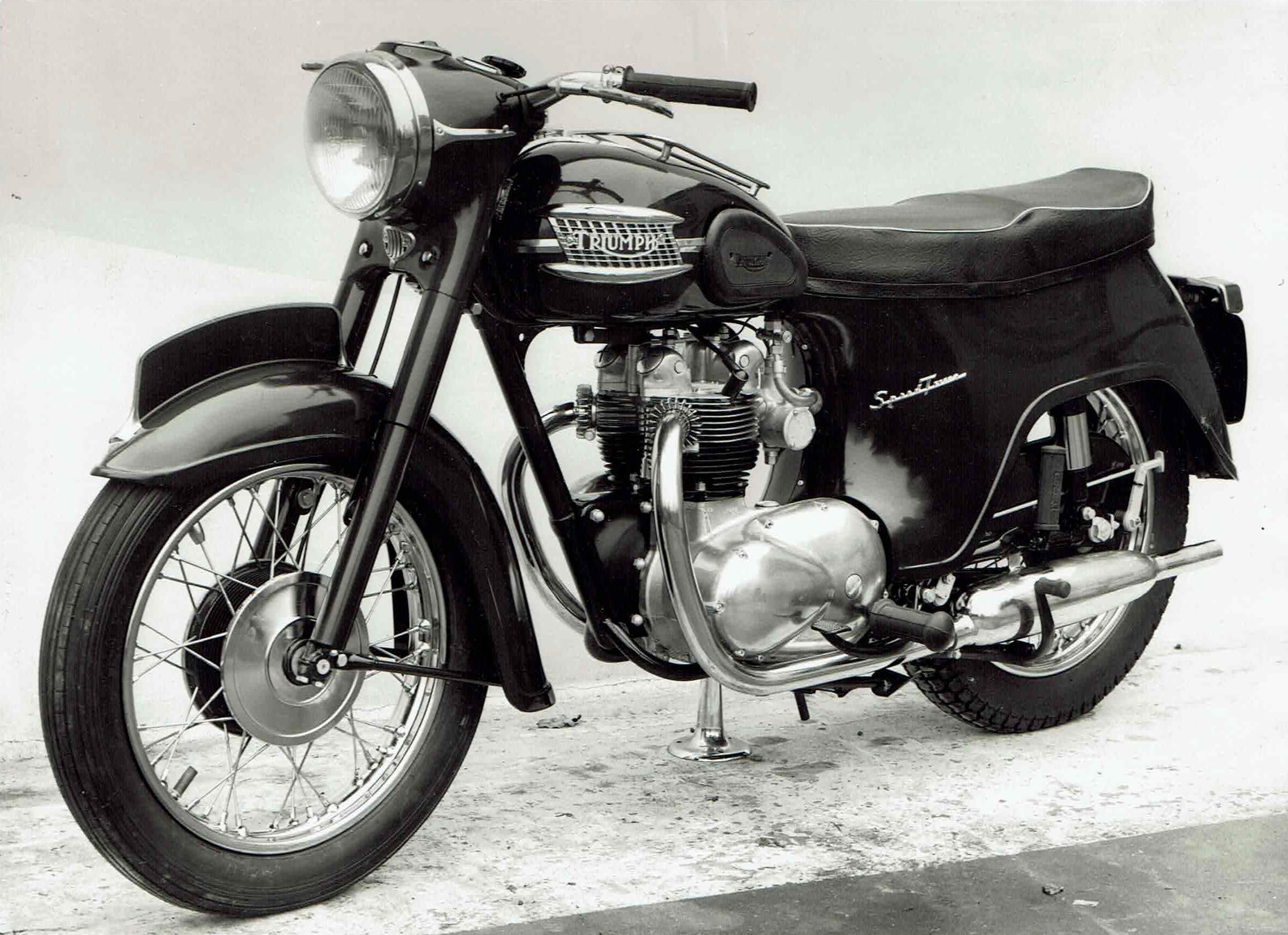

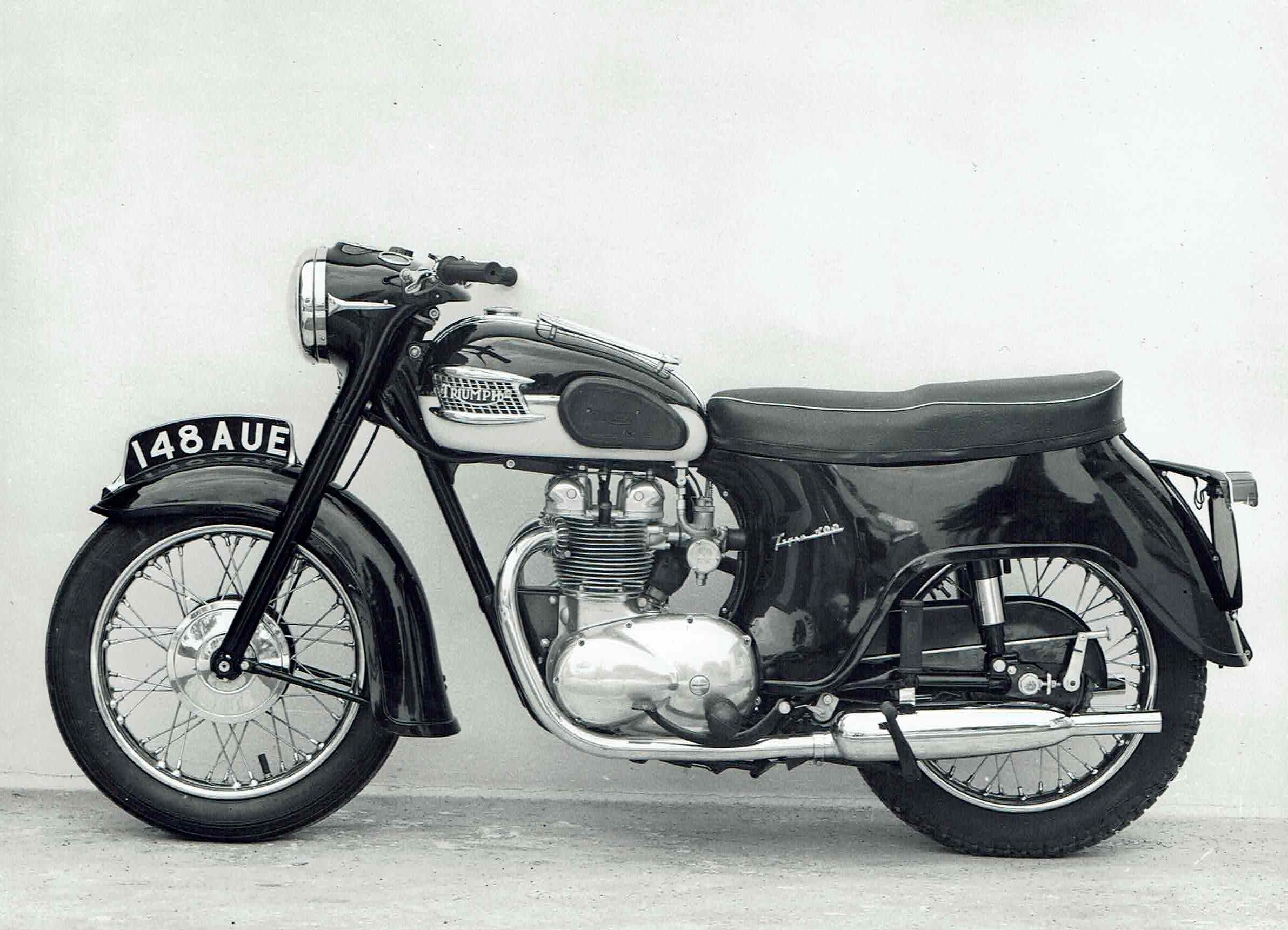

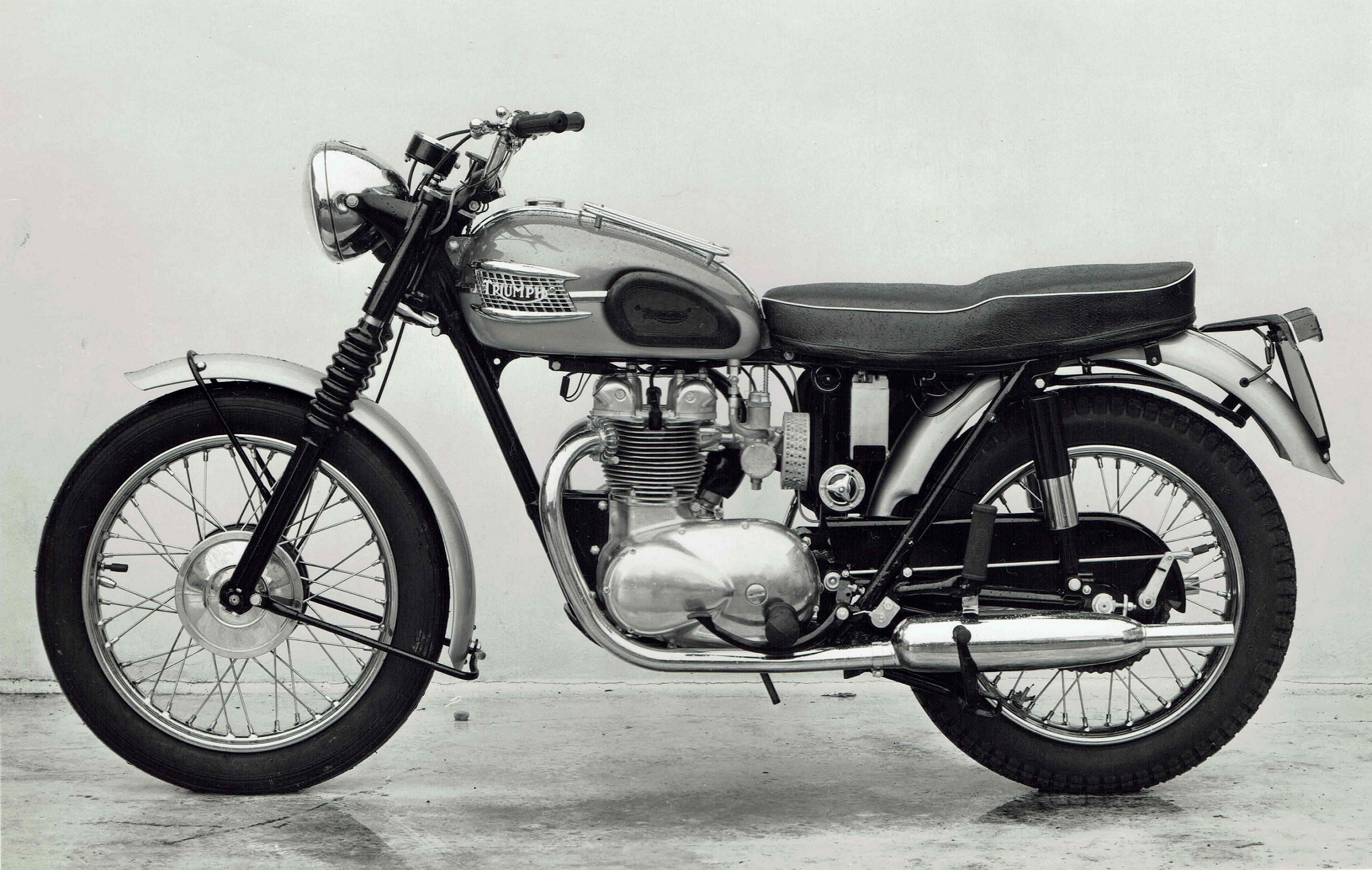

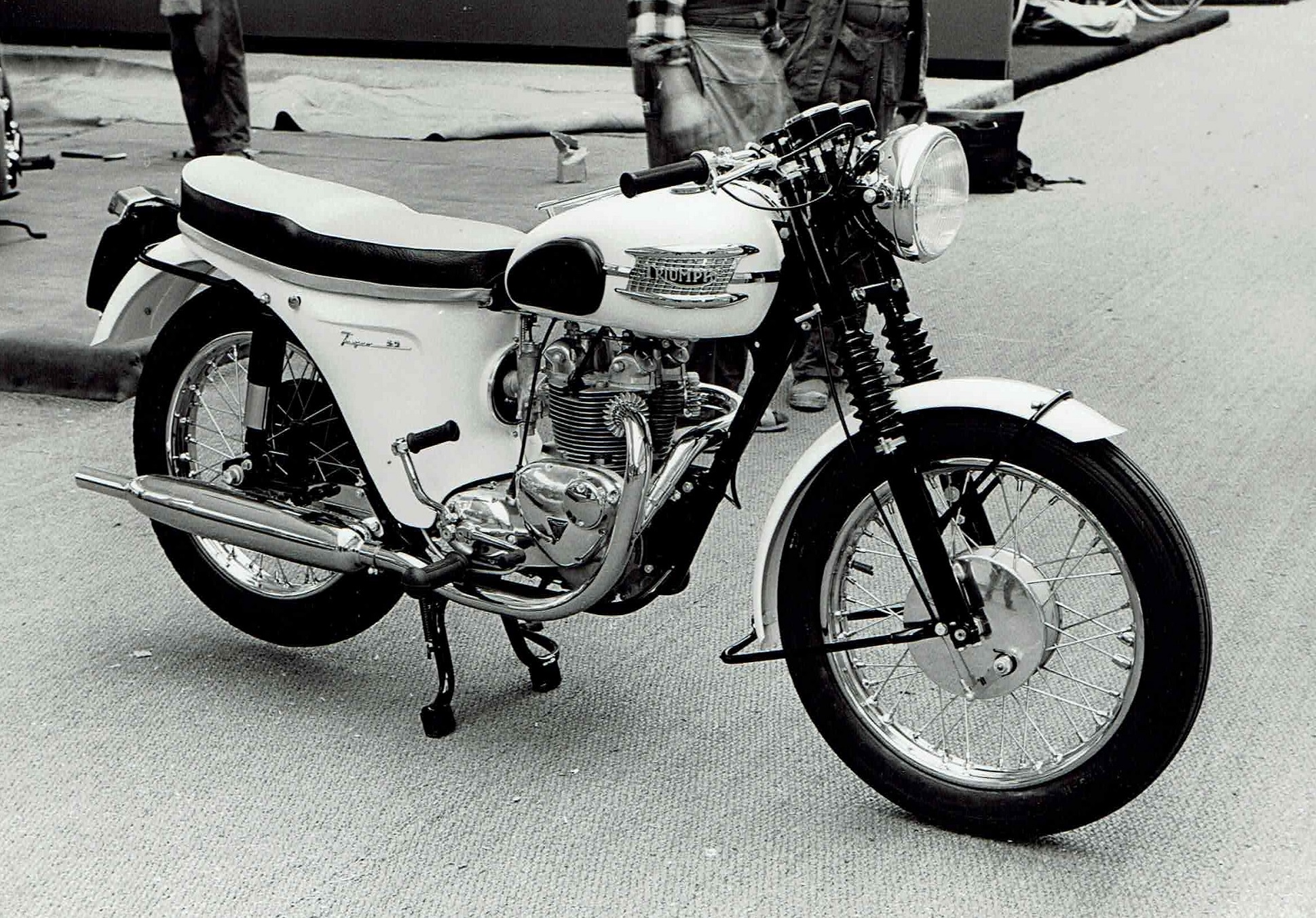

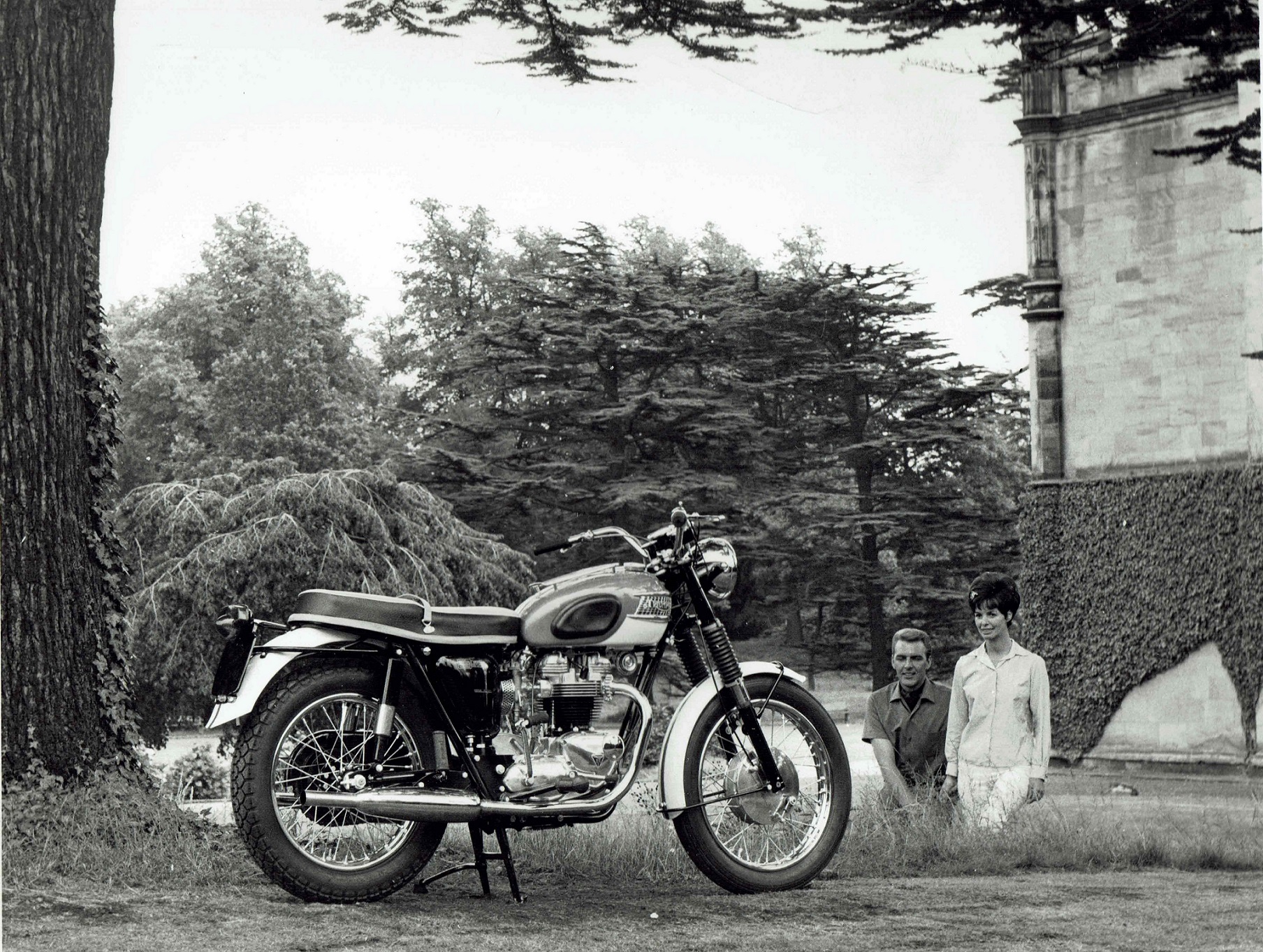

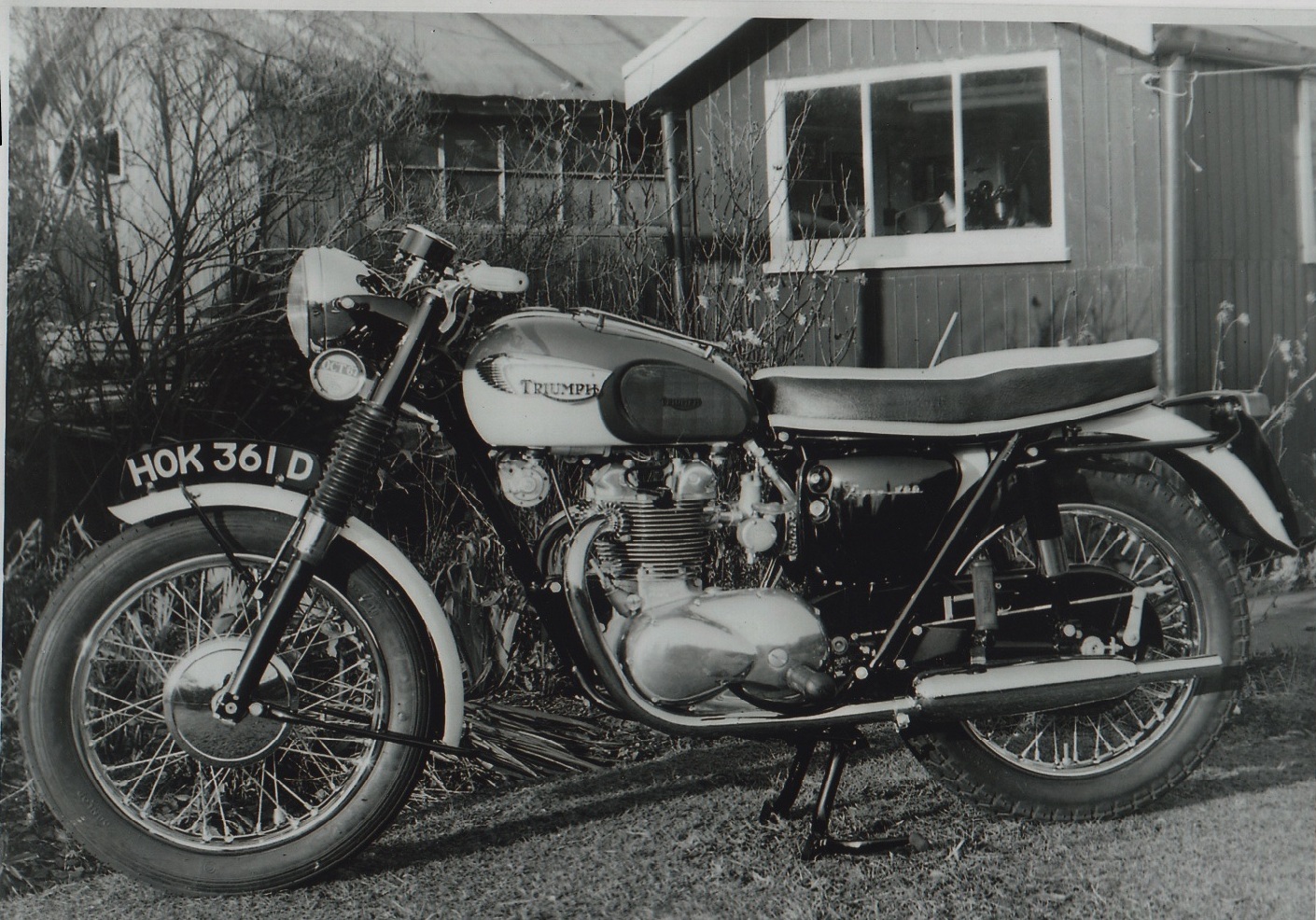

One of the very early production models in a publicity shot, from the VMCC Library Collection.

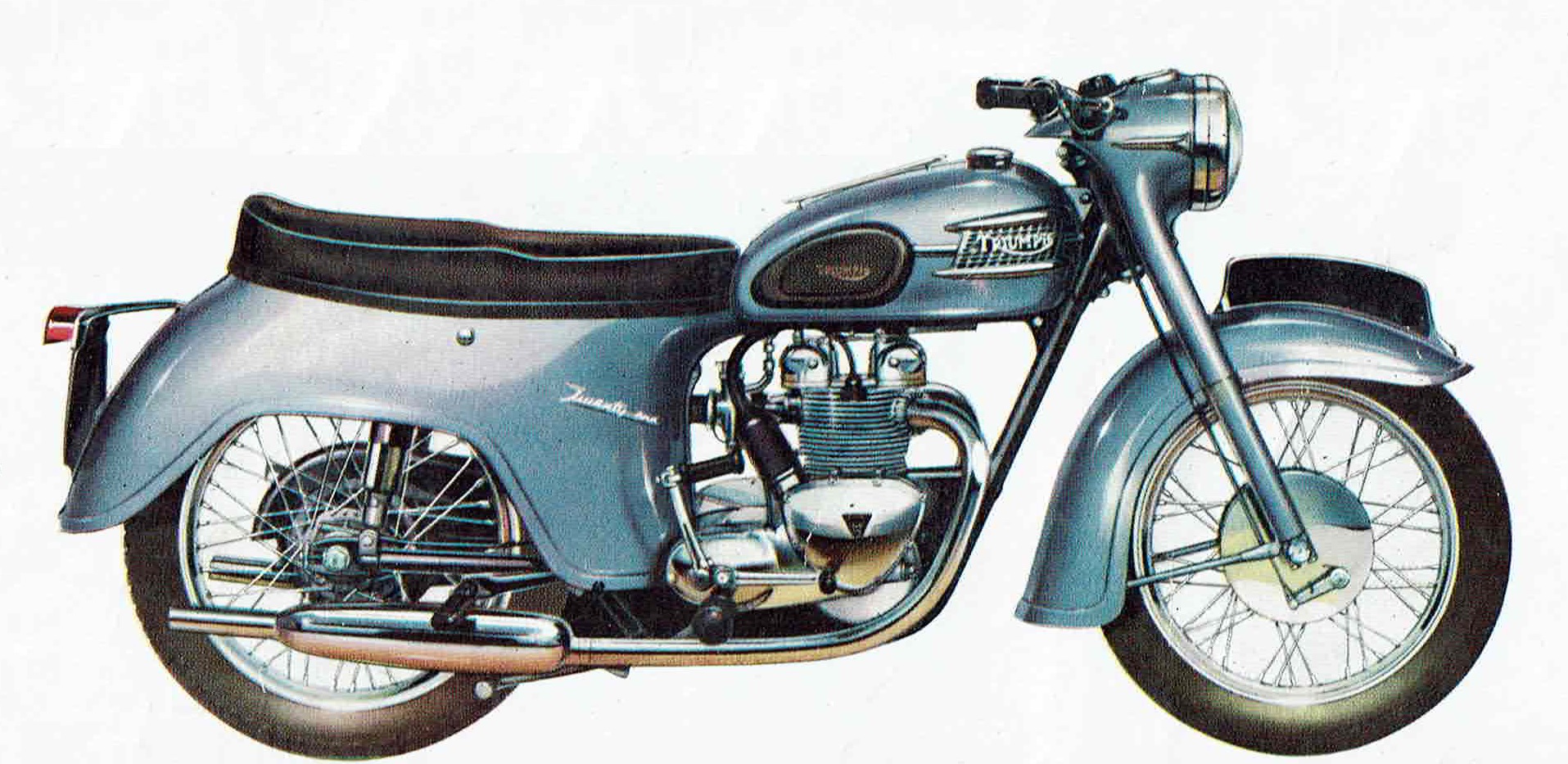

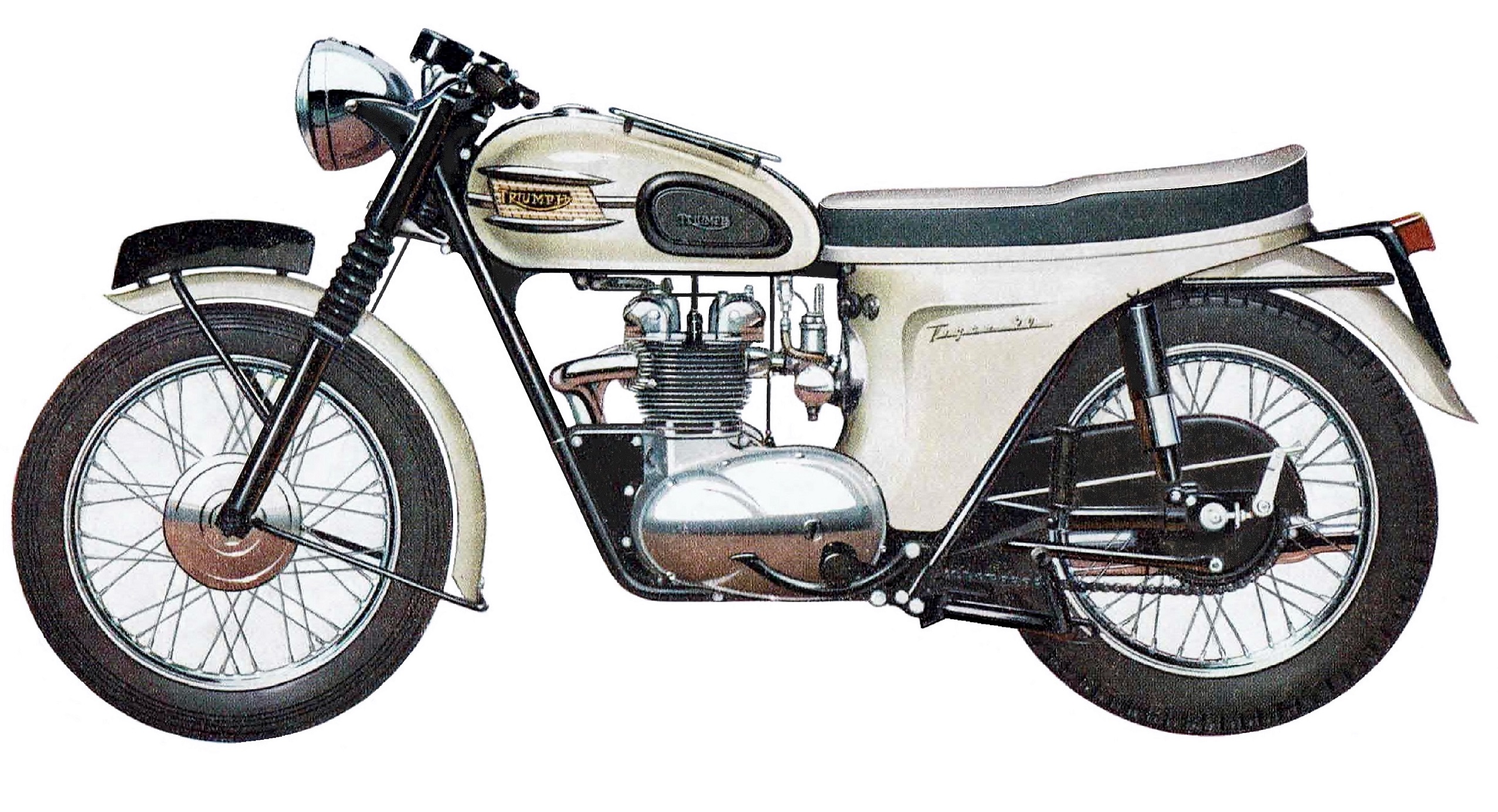

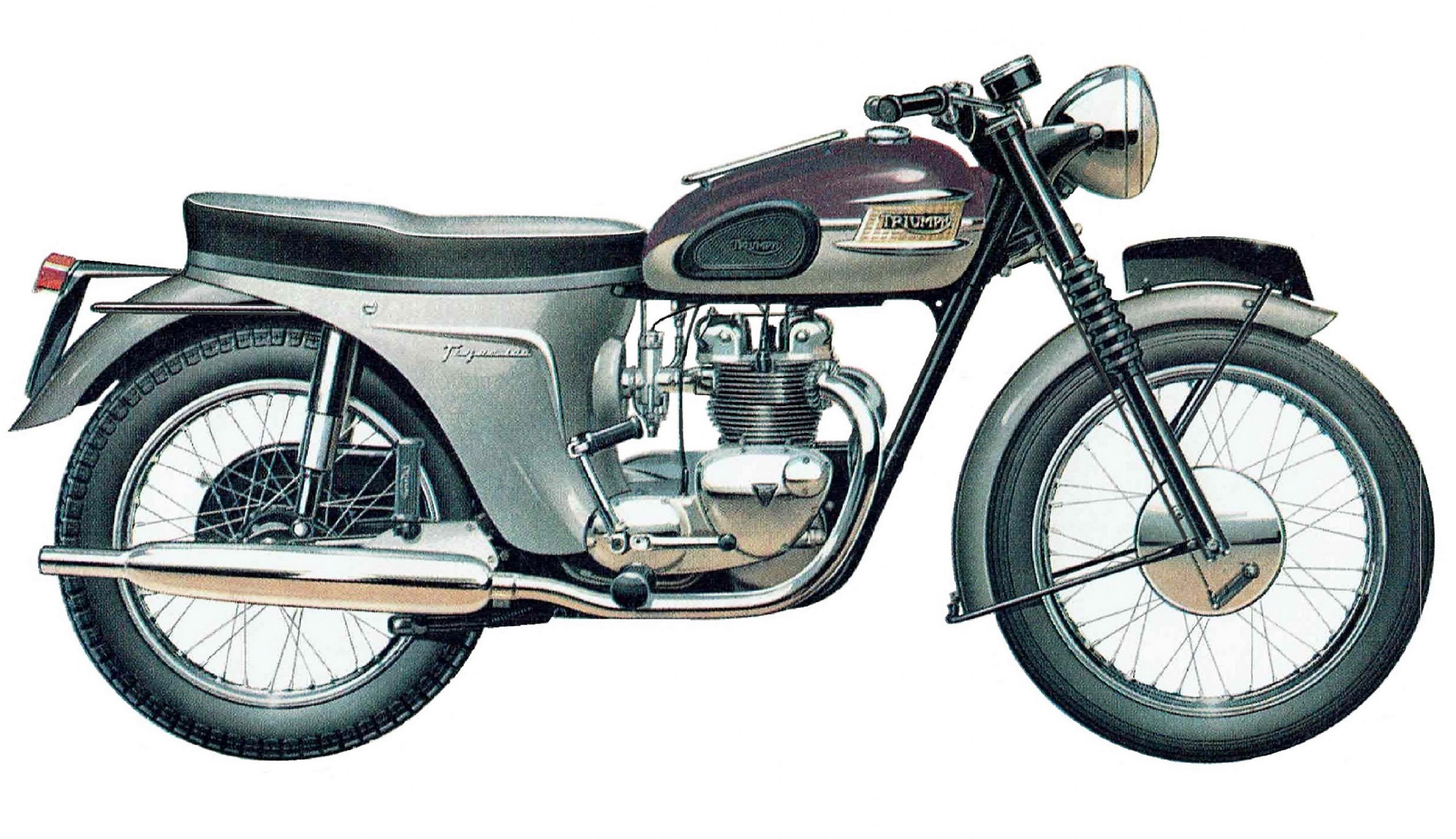

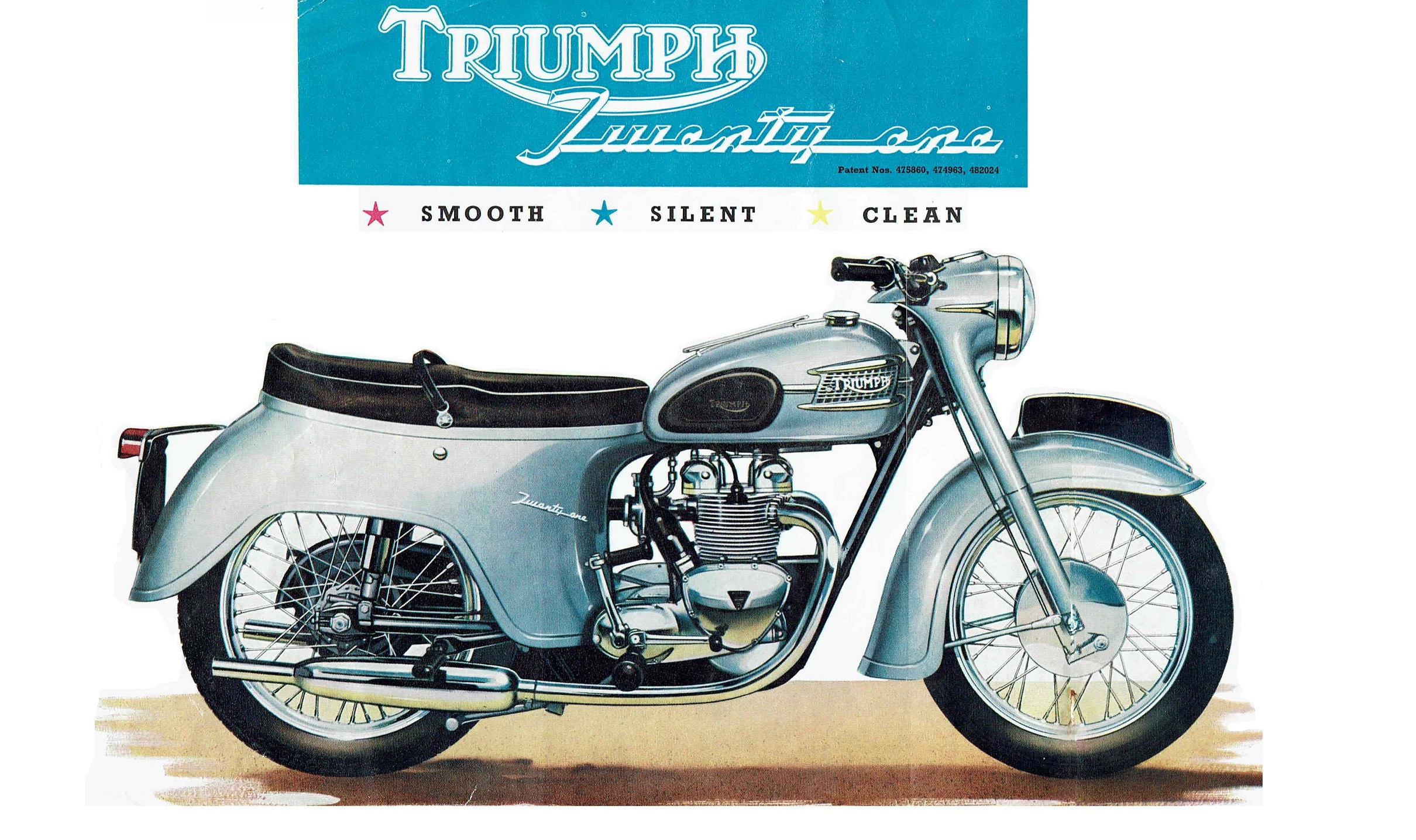

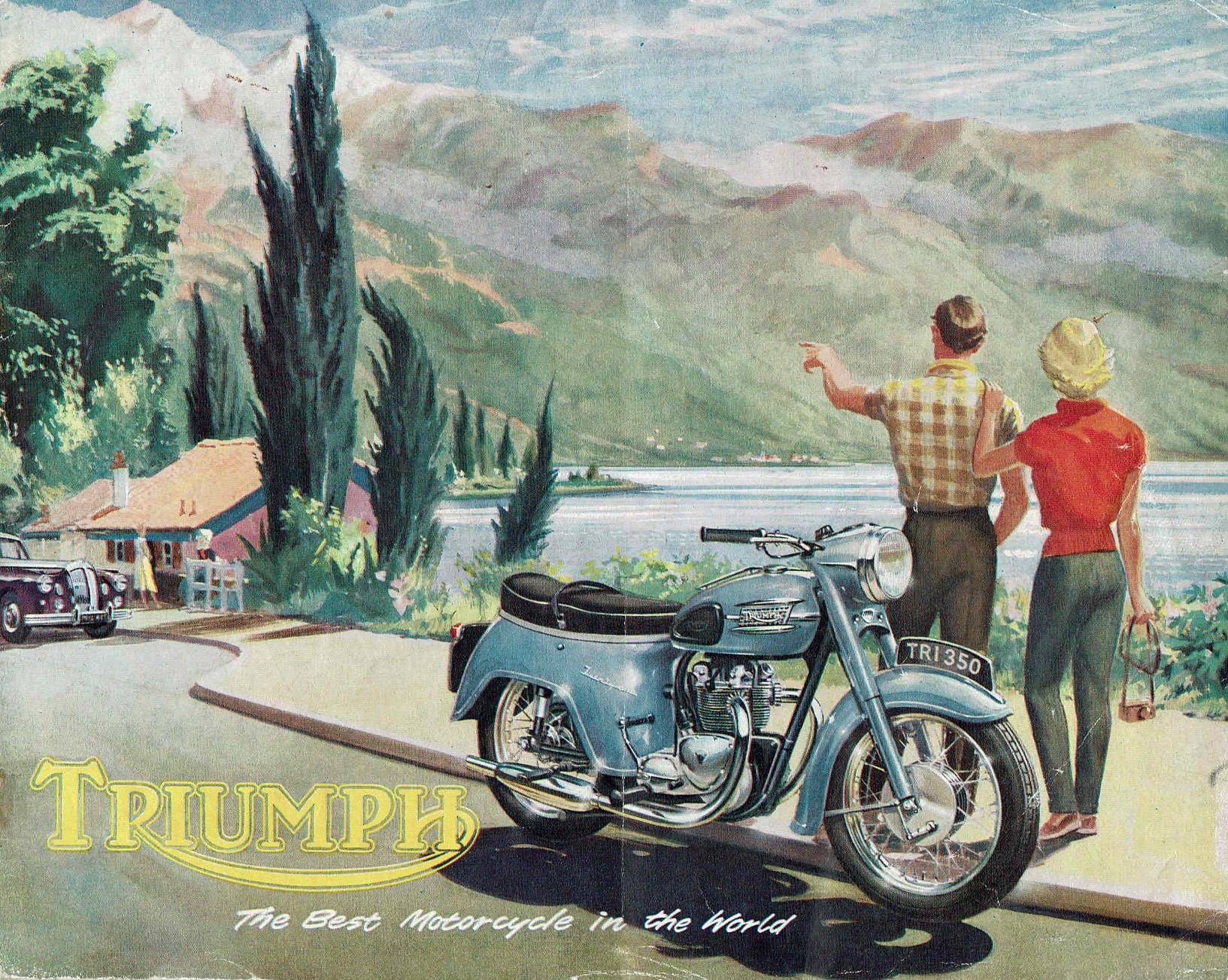

The T21 was designed from the outset as a machine incorporating for then; modern features and aimed to attract new buyers looking for clean inexpensive transport.

Named in honour of the Company’s 21st Anniversary, It is the first Triumph model to be fitted with the Bathtub enclosure.

The design brief was for a clean, high performance, 350cc roadster and the components and specifications applied reflect this.

Many parts for the T21 were taken from the T20 (Cub) and also the 500cc and 650cc machines, the abridged parts list published in April 1957 details all the parts shared with the other ranges, you can obtain a copy of this useful document from the VMCC Library, please quote ‘Triumph Article 673’ in your correspondence.

The Frame (pinned and brazed) comprises a single tube loop main frame with castings for the headset and rear engine support/swing arm. A bolted on sub frame supports the seat and rear suspension while additional welded on brackets are provided for other components.

The main frame is made from 1 3/8 OD 12 gauge tubing, duplex frame tubes for supporting the engine are 7/8 14 gauge, while the sub frame is a combination of 1 inch 15 gauge tubing for the uprights and 7/8 14 gauge for the seat support base. The headset and engine bridge support are malleable-iron castings.

For this early frame the Trail is 64.5 degrees as this matches Triumph practice for the period.

The forks are oil damped of conventional Triumph design for the period featuring chromed stanchions held in malleable cast iron brackets with the sliders supported by sintered bronze bushes. The long internal springs and damping control are housed within the stanchions. Externally there are painted covers. The lower sliders feature cast clamps and at the lower end is a mudguard support that can be hinged down to support the front wheel to assist in wheel removal.

The recommended quantity of SAE 30 Oil for each fork leg is 150cc.

The headset is enclosed by the trademark Triumph Nacelle, made in two parts with chrome trims disguising the joins, the Nacelle houses the headlamp with pilot light, combined ignition and lighting switch on the right, ammeter on the left, the speedometer and the horn. The steering damper knob is also mounted on the Nacelle. Shaped Rubber grommets are used where the handlebars pass into the nacelle and these additionally support the control cables and wiring.

The steering stops are associated with the lower fork bridge and there is a facility to lock the steering with a padlock.

The Headset itself is the usual pattern of cups pressed into the machined head-lug with cones, one fixed (bottom) and one adjustable; bearing onto the ball bearings, 24 in each cup. Adjustment is provided by a turreted sleeve nut in the top yoke that is locked into position by a pinch bolt and specialised nut. By inserting a tommy bar underneath the nacelle the headset can be adjusted once the pinch bolt is slackened.

The slightly upswept 1inch handlebar is attached by U bolts to the upper fork yoke, the brake and clutch levers are plain with vertical clamps and feature distinctive “One Finger” adjustment of the clutch and brake cables. This type of adjuster slides easily within the lever clamp and has a knurled adjuster turning half a turn at a time to change the cable tension. On the right the handlebar is swaged down to 7/8 in for the Twistgrip.

On the left is a Lucas 25SA Combined dip/horn switch attached to the Clutch lever by a specialised clamp (Alloy casting), the wiring is grey. The Throttle on the right is the Doherty pattern and features a curved a sleeve so that the cable enters the nacelle smoothly, the throttle friction clutch is operated by a small adjusting knob.

The grips are similar to the Amal Pattern, Black, quite thin with a fine raised finish and embossed with the Triumph Logo.

The Ignition/Lighting switch is the Lucas PRS8 Type the three-position switch controls the Pilot lighting and headlamp. The Speedometer is the 120 Mph Smiths Chronometric with the trip meter operated by an extension accessible within the Nacelle. The Ammeter is the Black faced Lucas BM4 8-0-8 ampere type while the hidden horn is the Lucas HF1441 model. Look carefully on the reverse for the date code applied to all Lucas components.

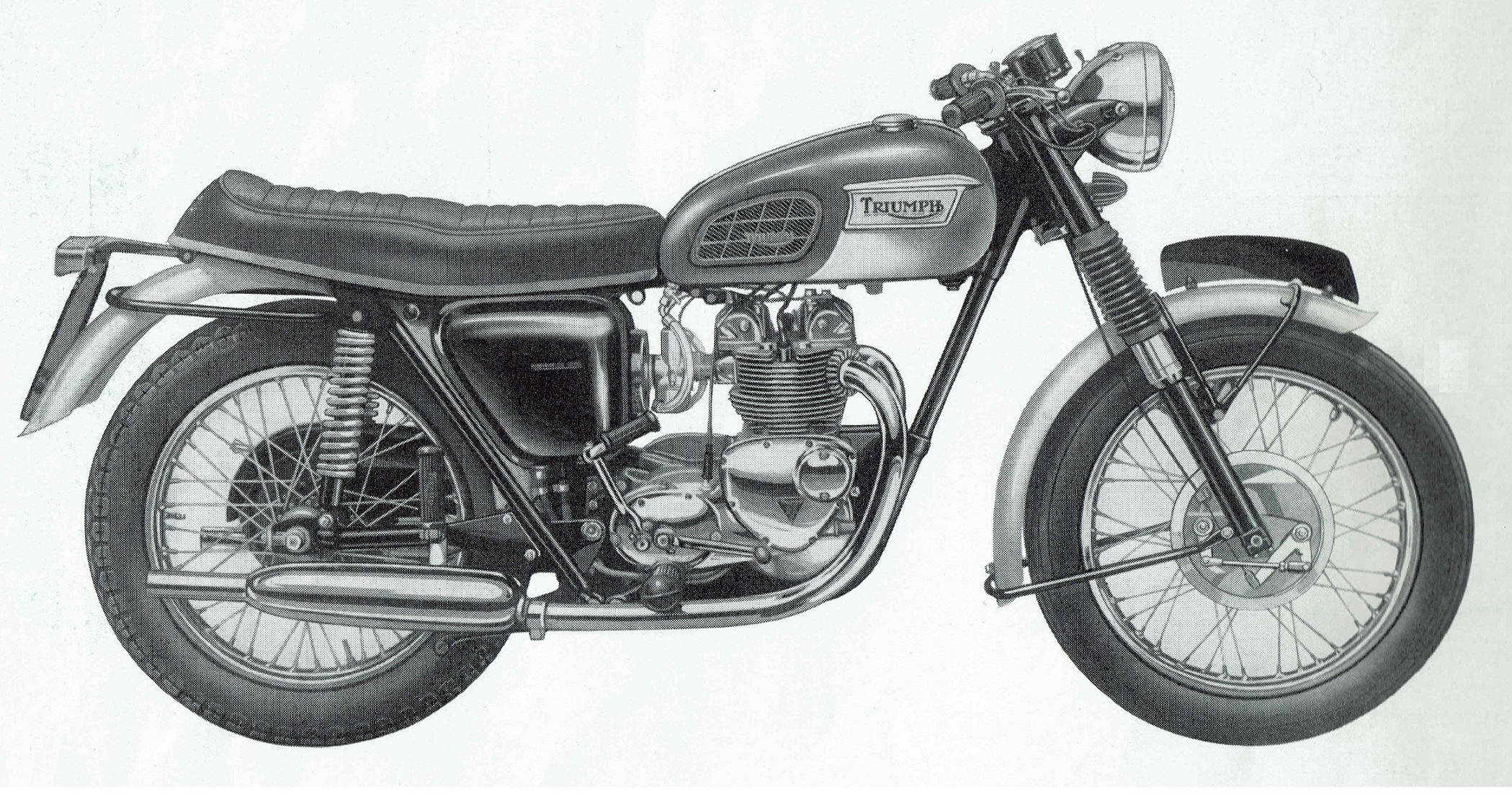

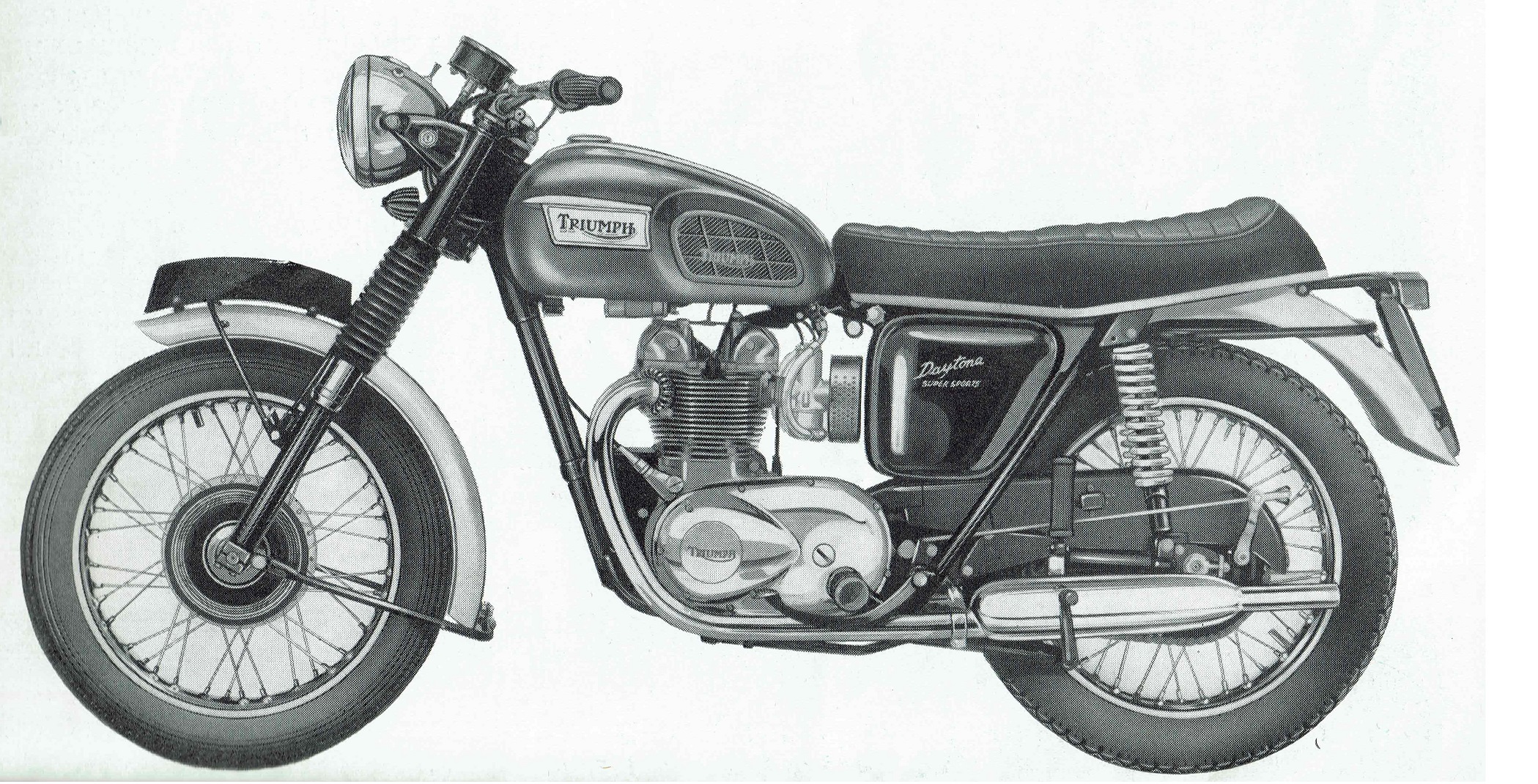

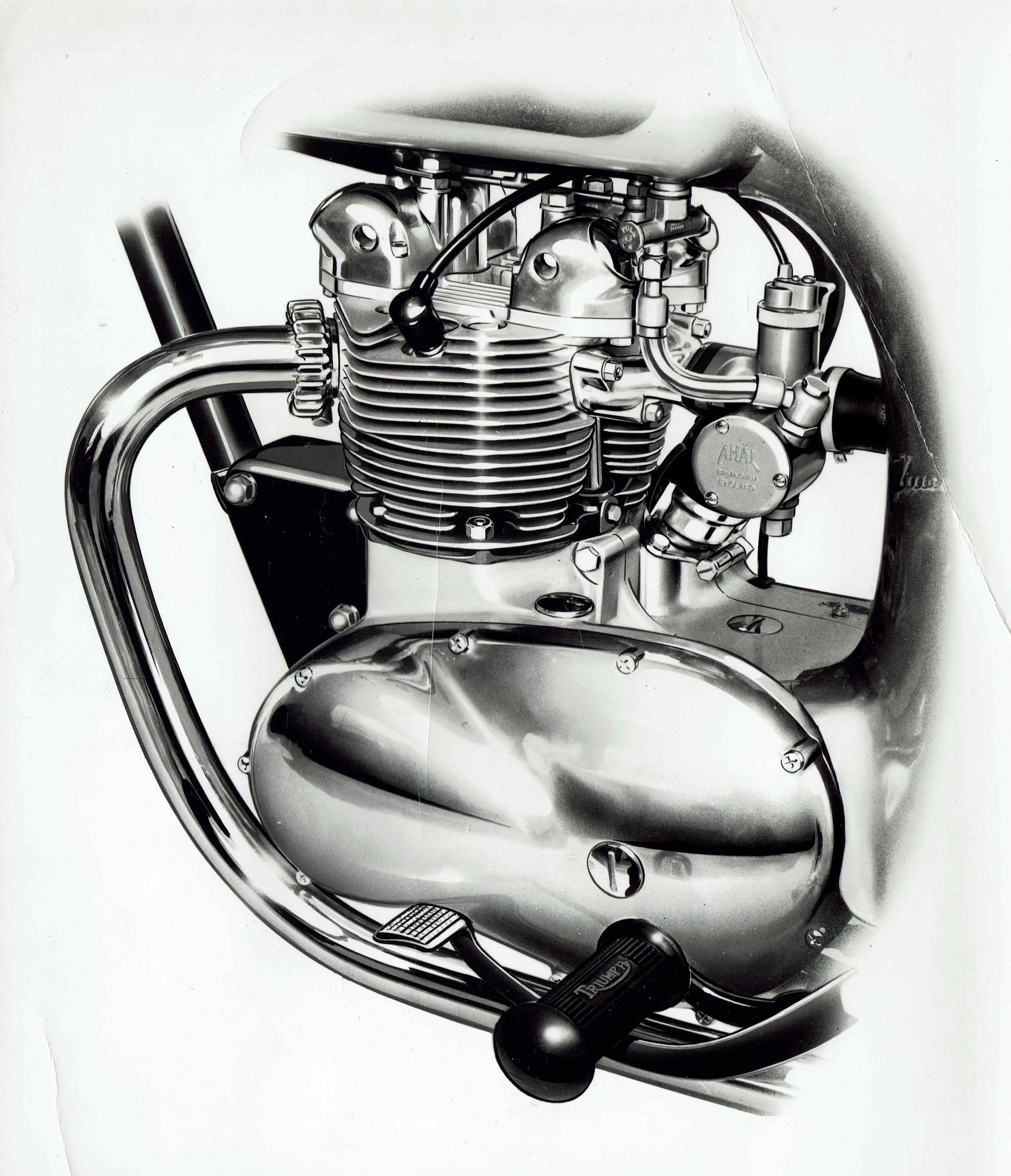

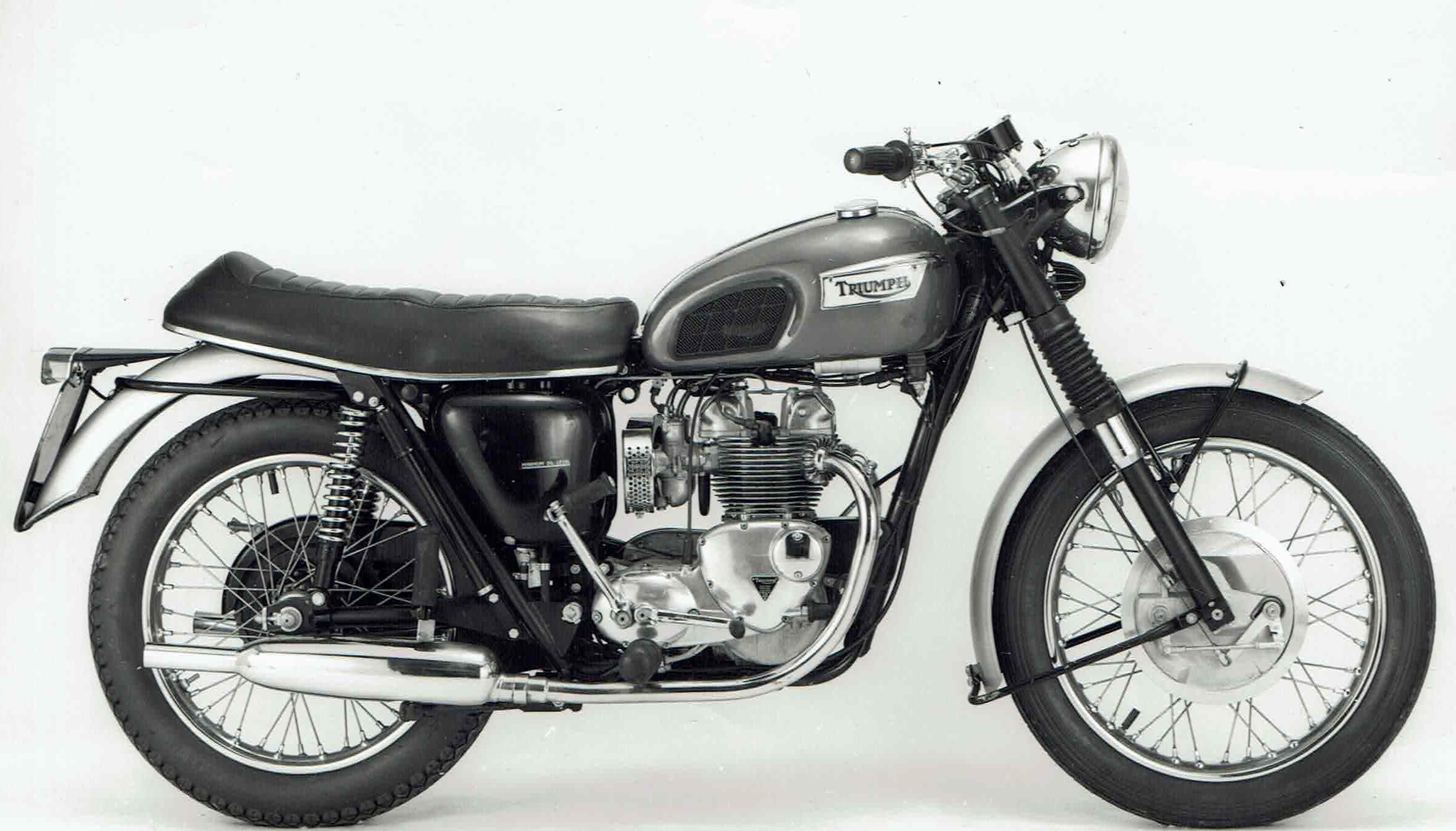

Factory Portrait of the up-to-date engine.

The engine for the T21 was totally new, the first Triumph Twin engine to feature unit construction with the gearbox housing as part of the right hand crankcase casting. The design allows the gearbox to be dismantled without disturbing the remainder of the engine. This form of Unit Construction with the integral gearbox had been applied to the Triumph Terrier for 1954 and continued on in the Terrier and Cub Models with the larger Twins changing in 1963. The 348 cc capacity is achieved with a bore of 58.25 mm and a stroke of 65.5 mm, the crankshaft is single forging (EN.16B Steel) with the central flywheel attached by radial bolts, very early machines feature straight sided crankshaft webs. Within the crankshaft is the removable sludge trap designed to assist in the filtration of the engine oil by separating out particles by the centrifugal action of the crankshaft. Oil is fed to the big end bearings through drillings associated with the sludge trap. On the left of the crank is the single row ball drive side bearing (Hoffmann Metric 330) while on the right is a VP3 Copper Lead bearing bush which is perforated so as to provide pressurised oil to the rotating crankshaft. From H500 the Timing side Crank Journal is heat treated and ground.

The connecting rods are steel stampings, split to hold the white metal thin wall big end bearings and fixed with special high tensile blind bolts and lock nuts. The small ends are pressed in phosphor bronze bushes.

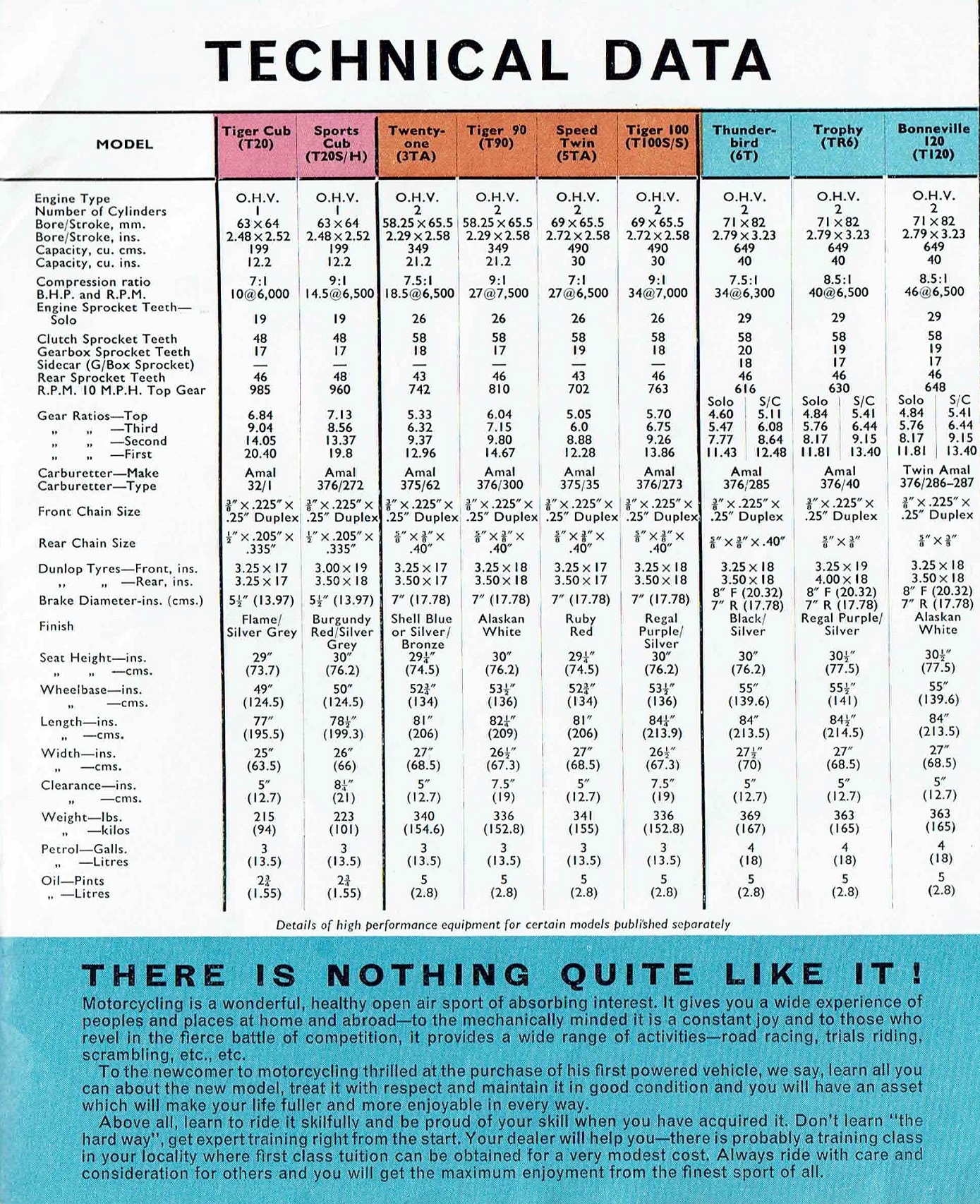

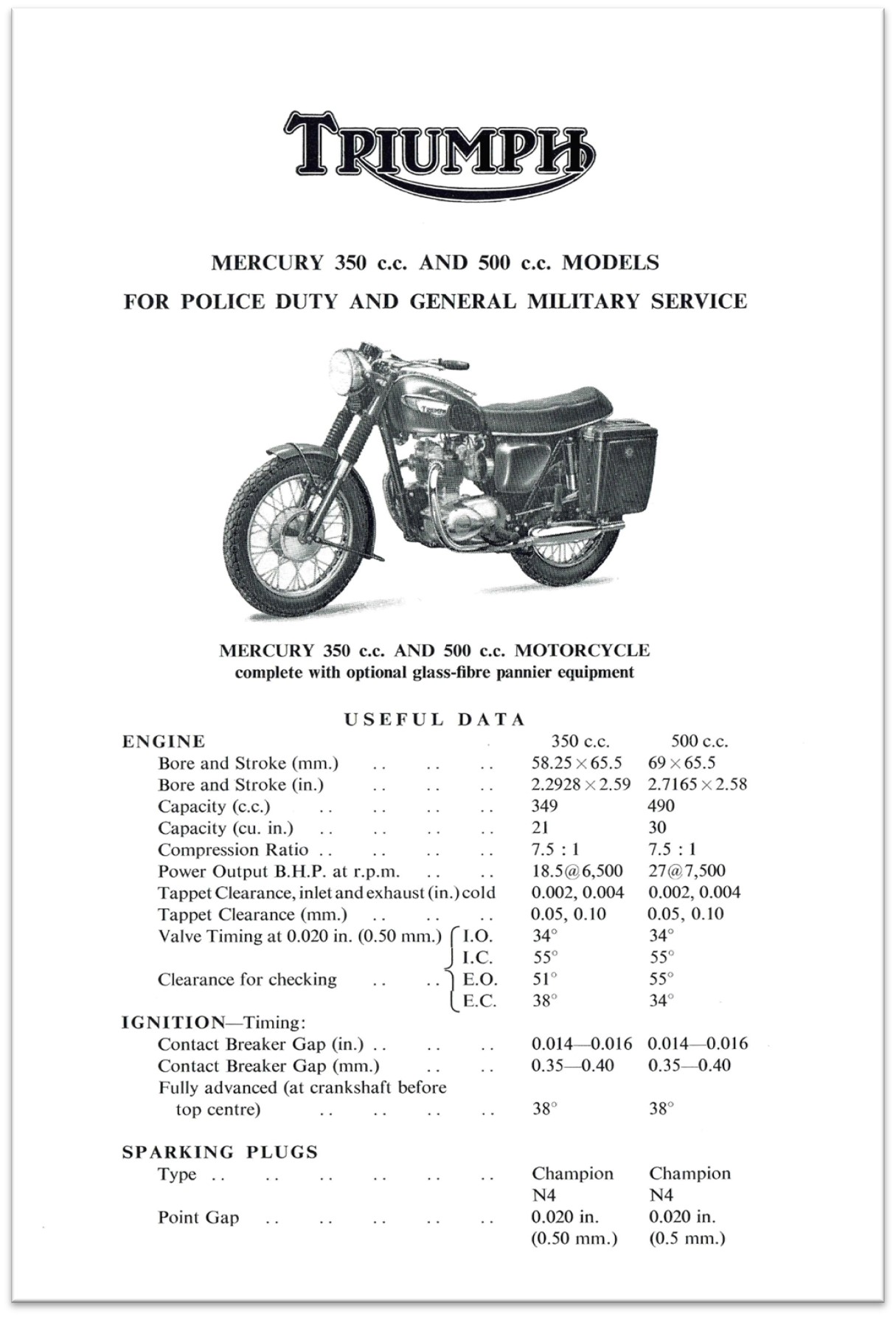

The engine is quoted as producing 18.5 brake-horsepower at 6,500 r.p.m using 7.5:1 pistons.

The finned iron barrels are painted in silver heat resistant finish (see notes) and attached at their base by 8 short specialised studs and nuts. Between the barrels fore and aft are found the chromed push rod tubes which contain short pushrods operating on paired tappets; housed within removable blocks in the cylinder base.

The pushrod tubes are sealed with specialised silicone rubber washers at either end.

Note… The Pushrod Cover arrangement is altered many times over the years and you will see numerous variations in parts. Sealing the tubes and the barrels always presented problems and was never really overcome successfully. Careful assembly occasionally using some sealing compound and new correct parts will minimise but is unlikely to completely eliminate leaks and many machines in regular use will have issues that develop over time.

Leaks at the base of the barrel are often caused by oil creeping up the outside of the tappet block as this is not fully sealed by the cylinder base gasket. Oil leaks can also be attributed to oil creeping up the threads of the two studs closest to the timing cover as the stud holes open into the crankcase adjacent to the camshafts.

The Tappets have stellite faces to reduce wear, are retained in position by the guide blocks and lubricated by oil draining from the cylinder head down the push rod tubes, each tappet is partially hollow with oil collection and delivery holes arranged to ensure adequate lubrication in the guide block while the cams themselves are lubricated by oil splashing from the rotating crankshaft and also dropping from the tappet blocks.

The well-designed light alloy cylinder head is fixed by 8 specialised bolts, four of which pass through the rocker boxes; these have paired rockers moving on hollow hardened shafts. The rockers feature drillings to allow oil to be fed to the adjustable tappets, these adjusters are assessed by removable caps on the rocker boxes. Above the rocker boxes, is the branched oil feed pipe, oil is provided to the rocker shafts via drillings within each box. Each pipe is attached by a shouldered bolt running through the box and sealed with soft copper washers. The nuts associated with the oil ways are domed and cadmium plated. Additionally attached to the forward head bolts are the paired flat metal head steady’s running to an attachment point on the frame, readily visible in period photographs.

Early Cylinder Heads appear to have smaller exhaust ports and stubs than later heads look for the casting number 3699 to identify an early example.

On the cylinder head near the Right Inlet Valve you will find a stamped alpha numeric code, these seem to show a date relationship, I am studying these but have yet to decipher the information, the alpha numeric code is seen on all ‘C; range heads.

The paired case hardened nickel steel camshafts run in plain bronze, replaceable collapsible bushes on the left and un-bushed within the right hand crankcase, oil is supplied to the un-bushed ends and the inlet camshaft bush by collectors and galleries, and oil scrolls assist distribution and lubrication.

The Inlet camshaft additionally operates the paired plunger oil pumps, the distributor drive and the timed breather system. The camshafts are located with steel plates and countersunk screws (1/4 BSF), punched on assembly so as to prevent them loosening. The camshafts are keyed to the timing pinions which feature a short screw thread to allow a special tool to be fitted to assist removal of the pinion. This tool is also designed to aid replacement of the pinion and to remove the crankshaft sprocket.

The breather system is designed to ensure a partial vacuum within the crankcase when the engine is running. The inlet camshaft is hollow with a drilling part way along its length, at the end a light spring and keyways retain a disc that is pierced by two holes (triangular) and as the camshaft rotates the holes in the disc selectively correspond with two holes in a plate secured by the camshaft bush. The holes open as the pistons begin their descent. Any escaping gases and oil pass into a vent tube that emerges from the crankcase adjacent to the gearbox sprocket.

The paired oil pump feeds pressurised oil via drillings to the timing bush and onwards to oil pressure relief valve located in the front of the crankcase. This features a Tell-Tail plunger to indicate the presence of oil pressure. From the relief valve a drilling takes oil to the Timing Side gears and then makes its way to the sump.

Oil having made its way from the crankshaft to the small sump within the crankcase is collected by the return pump via a filter gauze and curved pipe fixed within the right hand crankcase casting to be returned to the oil tank. The filter here is accessed via a removable cap forward underneath the engine.

The brass oil pump of conventional Triumph design features two steel plungers driven in unison by a sliding aluminium block. The feed plunger on the right is smaller than the return plunger so that the system runs on the dry sump principle. At the bottom of the pump are the valves, one for each side, consisting of a spring loaded ball bearing seating into the pump body. Both valves can be dismantled for servicing with the pump in situ. Under the crankcase near the oil pump is the junction and gasket for the oil feed pipes that sweep backwards towards the oil tank. Short lengths of Herringbone pattern oil Pipe connect the tank to the pipework with small pipe clips providing security.

Looking at the junction block the forward oil pipe is the feed and the rearmost one the oil return. (Simple to remember, forward is feed…rear is return)

The primary drive located on the left behind an oval cover is by a 3/8 non-tensioned, non-adjustable duplex chain to the Triumph 4 spring clutch of the period. The hub is fixed to the gearbox main shaft by a taper and located with a woodruff key. The clutch features 4 bonded and 4 plain plates. The clutch hub also incorporates a rubber shock absorber consisting of a rotating four vaned centre, located within eight shaped rubber segments. Within the primary drive case is also located the Lucas three wire Alternator, the rotor keyed to the crankshaft and secured with a shouldered nut and locking washer. Access to the final drive sprocket is via a removable plate (with oil seal) behind the clutch basket. The small attachment screws are punched to prevent them coming loose.

In a Tri-Cor Bulletin of 21st July 1961 the Chain Oiler Tube is described and is recommended to be blocked off to prevent oil leaks.

This blocked off tube remains on the “C” Range machines for several years and is the small hollow stud seen behind the Clutch corresponding with the lower part of the final drive sprocket !

The Clutch operating mechanism is by a quick thread screw; the cable enters the gearbox via a simple grommet on the top of the outer cover and connects directly to the clutch release lever within the gearbox. Replacing the cable requires removal of the entire outer cover and extracting the cable through the rubber cover of the distributor as well.

The four-speed gearbox features plain bushes for the lay shaft and ball bearings for the main, the gears are built up onto an intermediate cover while the outer cover contains the positive stop mechanism and clutch release screw. A useful gear indicator is provided attached to the selector quadrant. The gears are down for down arrangement and selected to make the most of the power available. Ratios are 13.0/9.32/6.30/5.31. The Gearbox sprocket has 18 Teeth.

On top of the gearbox is a recessed screwed filler cap and underneath a drain plug (1/2 in BSF thread) that also incorporates an oil level tube to ease servicing.

The gearbox is designed so that the gears and shafts except for top gear can be removed as a cassette once the clutch has been dismantled and without disturbing the final drive sprocket, chain and gearbox bearings.

The Engine Gearbox unit is held in the frame by shaped plates forward, the fasteners here are studs with distinctive dome headed nuts, while underneath, behind and above the gearbox are spacers and plates fixed by studs with conventional nuts.

The Carburettor is an 375 Amal Monoblock, there is no choke arrangement though the carb features the usual tickler arrangement and receives its air via a rubber hose from an oblong air filter attached forward on the left of vertical main frame rail. Carb size is 13/16 inch.

The twin exhausts are 1 inch in diameter and terminate into the Triumph style of tubular silencer this does not show the offset entry of later silencers. The silencers are attached to the frame by short lengths of tubing with trapped ends. The same support is used to attach the pillion footrests if these optional extras are fitted.

Recent documentation I have seen indicates that Triumph Silencers were made by Burgess one of the many Birmingham companies supplying the British Motor industry.

The short chrome plated Kickstart folds at the top, its ‘Triumph’ monogrammed rubber is closed at the end, while the chromed gear lever forward also shows ‘Triumph’

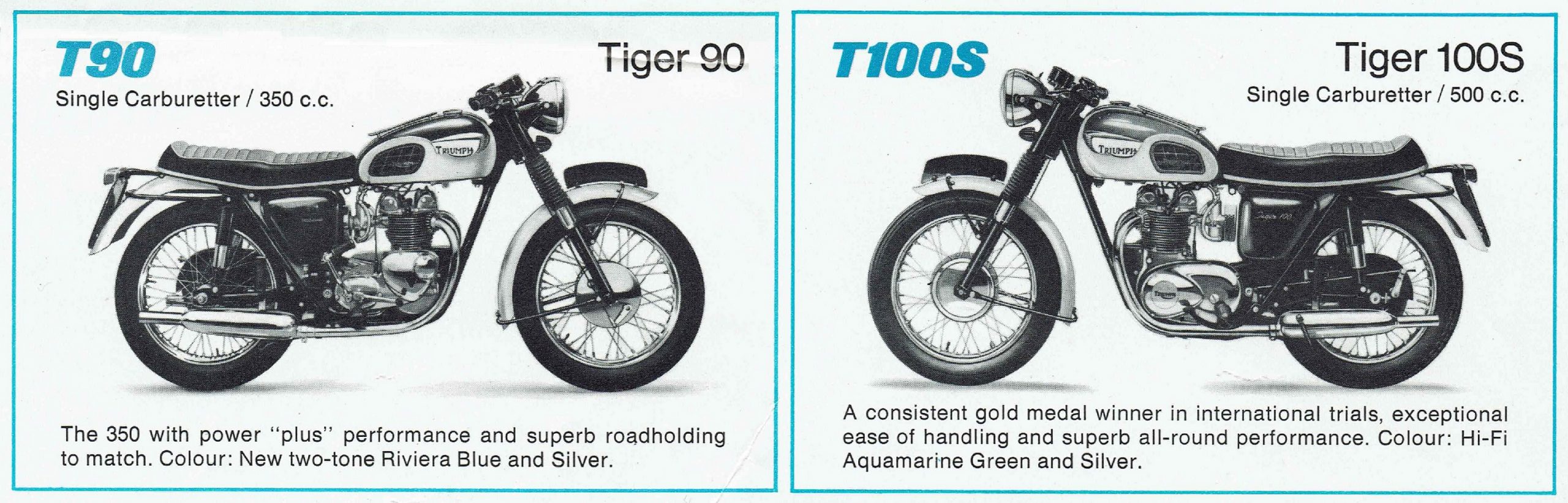

There is a Factory Photograph showing a Radio and Handlebar Fairing Equipped machine which features extended cylindrical silencers. This machine does not represent normal production specification and several details lead me to believe that this is a 1958 display machine to stimulate sales to the Police.

The Distributor located behind the right hand cylinder is the Lucas 18D2 Unit; reference 40573, driven by a skew gear from the inlet camshaft and is neatly covered and protected from the elements by a large rubber sleeve. The ignition timing is adjusted by loosening a clamp located on the crankcase.

The wheels are 17 inch, Dunlop WM2 Chrome rims 3.35 Front and Rear, The front tyre is a 3.25/17 inch Dunlop. Ribbed in the pattern of the modern Avon Speedmaster, while the Rear is a 3.25/17 inch Dunlop universal; the tread pattern of the modern Avon SM.

New for 1957 is the full width front hub, painted silver with a 7inch lightly polished alloy brake plate on the right and a shaped chromed hub on the left showing pressed concentric circles. The brake shoes fitted are not fully floating at this point in production while the cable stop fits on the lower fork.

The brake cable is additionally supported to the mudguard by a small P bracket.

The rear wheel features the common hub from the other Triumph models; there is a combined tubular brake torque stay and lower chain guard. Like the front brake the rear brake shoes are not fully floating.

A single piece upper chainguard attaches to the left side of the swing arm using a specialised fastening at the rear and can swing up to assist wheel and or chain removal once this fastening is loose. The pivot for the chainguard is associated with a small bracket bolted to the swing arm.

Both sides of the rear axle show shaped spacers and have the effective Triumph type chain adjuster, all parts cadmium plated.

It is quite normal for the left adjuster to foul the brake plate when set to the minimum chain length. The nuts associated with the adjusters are an early type of ‘Nyloc’ fastener,

it is important to use this type here.

The Brake rod adjuster is simple in form, T shaped and cadmium plated or chrome plated.

Standard Girling Rear Shock Absorbers (SB3 4234) using 100 lb springs are fitted with painted/chromed covers.

Extended length is 11.9 ins, compressed is 9.4 ins.

The Lucas Brake light switch, new for 1957 is the 6SA unit and operates by movement of a small ear on the brake lever, the switch itself attached to the brake torque stay nearby. The cables to the switch pass through a moulded rubber cover. The brake lever pivots on a specialised trunnion bolting to an eye brazed to the frame, there is no provision for lubricating the pivot but it is located with a large Thackeray washer and nut. All the fasteners here are specialised.

The Smiths Speedo drive unit is the early angular form and appears ‘upside down’! With Smiths speedo drives there is a bewildering array with multiple of types, sizes and gearing ratios. All operate on the same principle (worm drive) and suffer from poor lubrication. The drive unit is arranged to be quickly removed so that the wheel can be taken off for repairs. The routing of the cable heads from the drive unit and follows the swing arm before curving up behind the oil tank towards the junction of the main frame and sub frame before running along under the petrol tank and into the Nacelle.

The ribbed and flanged front mudguard is the full (Roman Helmet) style and is attached to the lower fork sliders by a shaped brace; the lower mudguard stay loops within the mudguard and when released by a single nut is able to act as a stand to help with wheel removal. On the mudguard is fitted the front number plate fitted within a stylish chrome surround (Patented). The rear mudguard is hidden by the bathtub enclosure, which is a new Triumph feature for 1957. The Bathtub enclosure is made from two 22 gauge steel pressings bolted together with a rubber strip between them. The bolts are carefully hidden so that the finish is neat. The panels are supported by the seat loop and fastened by four self-tapping screws around the seat loop together with additional brackets associated with the fuel tank mount. Hidden underneath is a support stay running from the suspension mounts to a point at the rear of the panels. This is nicely illustrated in the description article in “The Motor Cycle” of 28th February 1957. The stay rarely survives and many restored machines omit this feature in error. It is not illustrated or mentioned in the parts book!

The rear number plate is attached by two nuts and bolts at the lower edge, the single upper mounting fits neatly between the Bathtub panels and no fixing is visible from the top.

On each side of the bathtub is found the Chromed ‘Twenty One’ script, while on the right is the removable chromed knob; which releases the seat.

The fuel tank 3½ Gallons (16 Litres) has fore and aft mountings, no tank top grid or central styling strip. Fitted are the chrome styling strips on either side of the Mouth Organ type Tank badge. There are Black rubber knee grips featuring the Triumph motif and are attached by two screws on either side. The 1957 Parts Catalogue has an illustration of an early machine and tank within the preface but the Petrol tank shown later is the later version.

The fuel tap is the Ewarts type which has a in tank filter with separate plungers for main and reserve leading to a single clear plastic fuel pipe connecting to the carburettor

All early machines do not feature the Parcel Grid and I am trying to ascertain if this is fitted to any 1957 machines.

The Oil Tank is hidden behind the Bathtub Panels suspended at the top by two flat steel strips bridging the frame, additionally there is a lower mount associated with the rear engine plate. The cap incorporates a dip-stick, while at the bottom is an extension to allow the drain plug to be reached by a spanner and a removable filter and connection for the oil pipes. By removing the cap, owners could see the returning oil pulsing out of the return tube which was arranged to be visible. Under the tank a T piece in the return pipe provided an oil feed to the rockers.

Triumph Petrol and Oil Tanks were supplied by A.J. Homer and Sons, Solihull, Birmigham who specialised in medium sized steel and aluminium pressings for the Motorcycle Industry. Several companies would have been suppliers of pressed components to Triumph, Ward Brothers were a long established company and it is not currently possible to identify which suppliers were used for pressed components such as the bathtubs and nacelle.

The seat (Supplied by Motoplas) has a shaped a metal base topped with Latex foam; the covering is Black Vynide for both the top and sides separated by white piping. The lower fringe of the seat cover nearest the base is in grey. There is a centrally fixed passenger strap. The seat hinges on the left, raising but restrained by a wire to give assess to the Air Filter, Oil Tank filler, Battery within it’s cradle, Rectifier, Coil and the Tools, which are housed in a moulded tray covering the rear mudguard.

The inner mudguard extends forwards and attaches to the frame at several points, using a tapped hole in the main frame forging as one of the locations, this tapped hole survives for many years and can be seen on all models up to 1967.

The early seat base is nicely illustrated in the parts catalogue and shows the rubber pad for the battery and also the export only Safety Strap.

The Lucas MA6 coil is attached by a loop bracket to the inner rear mudguard and angled to allow the HT cable to exit to the left.

Current Rectification is taken care of by the large Lucas 47111 rectifier mounted to the left of the coil on a welded bracket with the connections protected by a rubber sleeve.

Photographs showing the seat base of the early factory machines (Gloss Black) show an unusual foam rubber extension to retain the battery in position when the seat is closed.

The Lucas alternator is a composite of an RM13 Stator and RM15 Rotor, lighter than the RM15 but efficient at lower engine speeds.

The three cell; six volt Lucas PUZ7E/11 battery supplies charge for the all the electrical needs including ignition, the wiring to the alternator is arranged; in combination with the ignition/lighting switch to provide adequate charging capacity depending on load. There is an “Emergency Start” circuit.

Lighting comprises the Lucas 700 Motorcycle headlamp with Pilot light; look carefully for ‘Motorcycle’ written in the glass. The period Lucas catalogue details variations for export models. On the rear number plate is found the Lucas 564 combined tail/brake/reflector light, look for the Lucas part numbers. The plastic lens is attached by specialised slotted chromed fasteners; mating to studs that pass through extensions within the lens. Pattern replacements do not have these distinctive fasteners.

The finish for the 21 is confusing to say the least, (H1 to H100) are Metallic Silver Grey including the frame and engine mounts. From H101 the finish is Shell Blue Sheen including the Frame parts and engine mounts with only the number plates in Black. Sometime later the frame parts become Black! Possibly from H288 as there is a note in the front of Triumph Record Book 147

The cylinder barrels are shown finished Silver in the brochures but one road test machine shows these as black! The majority of the engine cases are un-polished apart from the three covers and the rocker boxes. These are not highly polished but generally show a satin sheen.

The fasteners for the covers are distinctive Phillips head screws in ¼ BSF.

On the Timing cover is the Triangular Patent Plate; this reads ‘Triumph 350 Twin’ Made under Patent Numbers etc.

Photographs of H120 show the machine having the external Pannier Brackets fitted but these do not appear in the 1957 brochure, the parts book or on period shots of other machines. From H301 Pannier Brackets are recorded as fitted to the frame but holes are not provided in the bodywork and owners must pierce the panels themselves to complete the fittings. The holes that show in the upper suspension gussets are part of the pannier fitting arrangement (these continue for years to come).

From H434 the Side Stand is recorded fitted as standard though this and the pillion footrests are advertised as ‘Extras’!

The Mainstand on early machines is not the ‘Easylift’ Stand indicated in the 1958 Catalogue published in October 1957.

Mainstands on all of the range are weak and prone to damage, distortion and wear. Later models use the same basic stand but with extension feet. Look for wear in the pivots, feet, and distortion where the Easylift action is inclined to distort the left forwards. Careful bending with heat and welding repairs can reclaim these stands.

Note that the stand pivot holes, up to 1966 are threaded (1/2 in 20 TPI BSF) to accept the pivot bolts which are then located with slim nuts and lock tabs.

The same thread form is found on the specialised pivot bolt for the brake lever though this uses a different type of slim nut.

The 57 Parts book in my personal collection does not illustrate all of the parts such as the front mudguard arrangement, exhausts or primary drive cover, it also shows parts fitted which will be appropriate only for the very early machines.

Interestingly part of the manual concerning part ordering is printed in French, Spanish and German

Frame technical data on the “21” and other models in the 1957 to 1960 range can be found in notes taken from the Johnson Motors dealer meeting at the Huntington Sheraton Hotel in January 1960. This interesting book was produced for the dealers and mechanics attending this event and describes pricing, sales, advertising, parts ordering and detailed technical data on both the Triumph and Ariel ranges.

For details of the various road tests for 1957 refer to the Magazine Articles Tab at the top of the page.

Notes for 1957

| 1957 | T15 | T20 | T20C | A Range | T21 | 5T | T100 | TR5 | C Range | TRW | 6T | TR6 | T110 | B Range | Total | % Sales | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Home | 1 | 3960 | 571 | 4532 | 244 | 618 | 495 | 47 | 1404 | 1028 | 42 | 729 | 1799 | 7735 | 37% | ||

| Export | 31 | 3011 | 1167 | 4209 | 294 | 608 | 686 | 88 | 1676 | 2099 | 2099 | 1620 | 1571 | 1872 | 5063 | 13047 | 63% |

| Other | 1 | 1 | 1 | 0% | |||||||||||||

| 32 | 6971 | 1738 | 8741 | 538 | 1226 | 1181 | 135 | 3080 | 2100 | 2100 | 2648 | 1613 | 2601 | 6862 | 20783 | ||

| % Sales | 0.2% | 33.5% | 8.4% | 42.1% | 2.6% | 5.9% | 5.7% | 0.6% | 14.8% | 10.1% | 10.1% | 12.7% | 7.8% | 12.5% | 33.0% |

The Sales figures shown are compiled from the surviving original Triumph account Ledgers held at Warwick University Modern Records Centre.

The now fragile; handwritten ledgers contain comprehensive details of salaries, stocks, materials, buildings, sales etc and are fascinating to study. I have compiled detailed charts of sales of all models from 1950 until 1969 when the records end and you will find these in my book along with other useful information and pictures.

UK registrations of motorcycles over 250cc for 1957 amount to 26498 machines with some 25000 British manufactured motorcycles exported. Look for the small Motorcycle and Scooter Guide booklets published by the Daily Mail for more detailed information.

For an interesting analysis of Motorcycle Sales from 1957 to 1969 look for the article in Motorcycle Sport Vol 10 No7 July 1969

The Reasons for the introduction and popularity or otherwise of the Bathtub are somewhat complex. It needs to be remembered that in the late 50’s and early 60’s the Scooter had become very popular and was seen as clean and inexpensive transport. Many UK manufactures attempted to enter the scooter market with new products Triumph included (Tina Scooter). There have been many attempts over the decades to sanitise mainstream motorcycling and the Bathtub was Triumph’s attempt!

Unfortunately for Triumph the market was moving and the family man who would previously bought a motorcycle for his daily use was now buying a small car and motorcycling especially in America was becoming a leisure activity where style was more important than cleanliness.

Neale Shilton in his book “A Million Miles Ago” indicates that development work on the T21 was done in some secrecy in Litchfield by Charles Granfield whom Edward Turner had recruited from Rolls Royce. Neale is the only source for this information and therefore it cannot be confirmed.

The book itself is an excellent read filled with stories of the authors long career with Triumph as export sales manager and the characters involved in the British motorcycle industry of the 1950’s and 60’s. It’s long been out of print but copies can usually be found on Amazon and other sites.

For the USA the Model Name ‘Twenty One’ conveniently described the cubic capacity, in the period literature this is not indicated and I believe that an Urban Myth has arisen that the model was named to convey the cc rather than the anniversary!

In 1956 by industry agreement there is no London Motorcycle Show the various manufactures would usually have prepared new models for display at this prestigious end of year event. Because there was no show Triumph did not complete development of the exciting new ‘Twenty One’ until early 1957.

Engine Production officially begins with H1 to H4 sometime after the 15th February 1957 though there will have been several months of activity previously to design and arrange a supply of parts for the revolutionary new model. These first engines are not built in the engine workshop but within the experimental department.

Production of engines H5 to H36 is on the 19th March 1957. H36 is sent to the experimental dept and production does not start again until the 13th April when new flywheel balance weights are applied obviously as a result of tests on H36. The engine record book during this early period is fascinating as it details a number of small changes and details, i.e. machines destined for Australia are fitted with +10 thou Pistons and Barrels.

There is an interesting anecdote of Percy Tait achieving 80 mph on one of the test machines in order to escape the pursuing press who were interested in this new and as yet unidentified model!

Complete machines H1 and H2 are recorded as being assembled on the 22nd February 1957 with H3 on the 28th and H4 on the 8th March, the first two machines are shown at the RAI Motorcycle Exhibition in Amsterdam from 28th Feb-10th March 1957.

H1 H2, H5 and H6 are sent to Stokvis & Zonen, Holland, H3 to Germany, H4 to Sweden, and H7 & H8 to Norway while other early machines go to dealers in Denmark, Malta, Japan, Singapore, Chile and Algiers. Machines H5 and H6 are known to survive.

H5 was sold at the Stafford Show Bonham’s Auction in April 2017.

The first machine supplied to a UK dealer is H39.

H39, H41, H45, H50-H52 and H88 are possibly test machines as though made in early 1957 are not recorded as dispatched until November, all of these are sent to UK Dealers with the Factory Records carefully amended.

H39 sent to Elite Motors Tooting Ltd. 951/965 Garratt Lane, Tooting SW17 on 15/11/57

H41 sent to Harveys, Lambeth SW8 on 15/11/57

H45 Sent to Pride & Clark, 158 Stockwell Road, London on 15/11/57

H50 Sent to Kings of Oxford on 22/11/57

H51 Sent to W. Shearings, 23 North Street, Bishops Stortford on 16/11/57

H52 Sent to Pride & Clarke, 158 Stockwell Road, London on 14/11/57

H120 (WAC 574) Sent to Cliffe & Sons, London SE1 on 15/5/57 pictures of this factory/press machine survive in the VMCC archive.

H71 appears to be the first official UK machine sent to Marble Arch Motor Supplies on the 27th May 1957. UK machines in general do not start until H120 (WAC 574) which is sent to Cliffe & Sons London SE1.

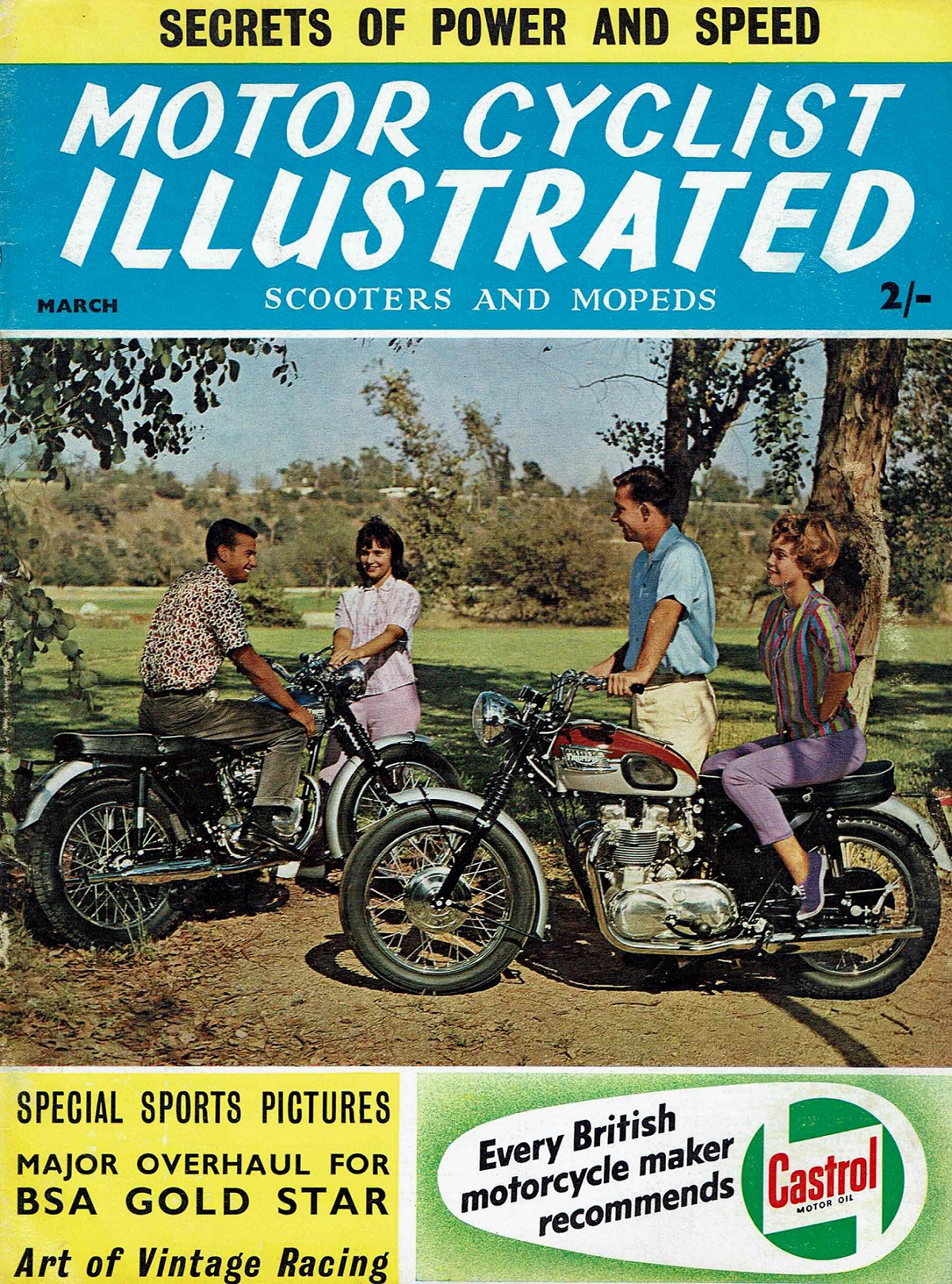

H71 is possibly registered TYM 21, this machine features in some early articles in Motor Cyclist Illustrated. Look for the June 1958 copy which details a 10,000 mile service and assessment undertaken at the factory.

The first USA machine appears to be H85 sent to Johnson Motors with H96 going to Tri-Cor but generally very few of these 1957 machines are sent to the USA.

There are photographs featuring one of these early machines taken in Baltimore where Tri-Cor were based, so it is possible to assume that this machine is H96!

Look for American Motorcyclist of November 1957 for the release article of the new model. Back issues of American Motorcycling can be found on Google Books.

Look for Cycle (USA) December 1957 as this has a Test and a nice illustration of Gill Stratton (Actor, Sports Reporter) with his new T21.

Most of these early production machines are exported with destinations as varied as Costa Rica, Algeria, Borneo, Mexico, Japan, South Africa, Australia etc.

In total some 485 T21 machines are exported for 1957, only 11 machines go to the USA, 5 to Johnson Motors and 6 to Tri-Cor.

Look for “The Motor Cycle” of 28th February 1957 for an extremely detailed and beautifully illustrated write-up. The machine featured is likely to be one of the very early machines H1 to H4 as no others had been manufactured by the date of the publication. Within the magazine are other promotional images and photographs.

Cycle (USA) of December 1957 has a road test on one of the early US machines.

The Motorcycle of 17th April 1958 shows WAC 574 (H120) on the cover though there are no further details or pictures in the magazine.

The VMCC in their archive have a copy of the press brochure together with some excellent photographs of early machines which show

details that are not normally visible.

The Price for the T21 is £ 217 without extras fitted.

Restoration of the model to a basic specification is not complex but availability of the parts such as the bathtub, front mudguard, nacelle, rear inner mudguard, tool pack and original electrical components make the bathtub models a nightmare for a full concourse restoration and costs will quickly outstrip the final value.

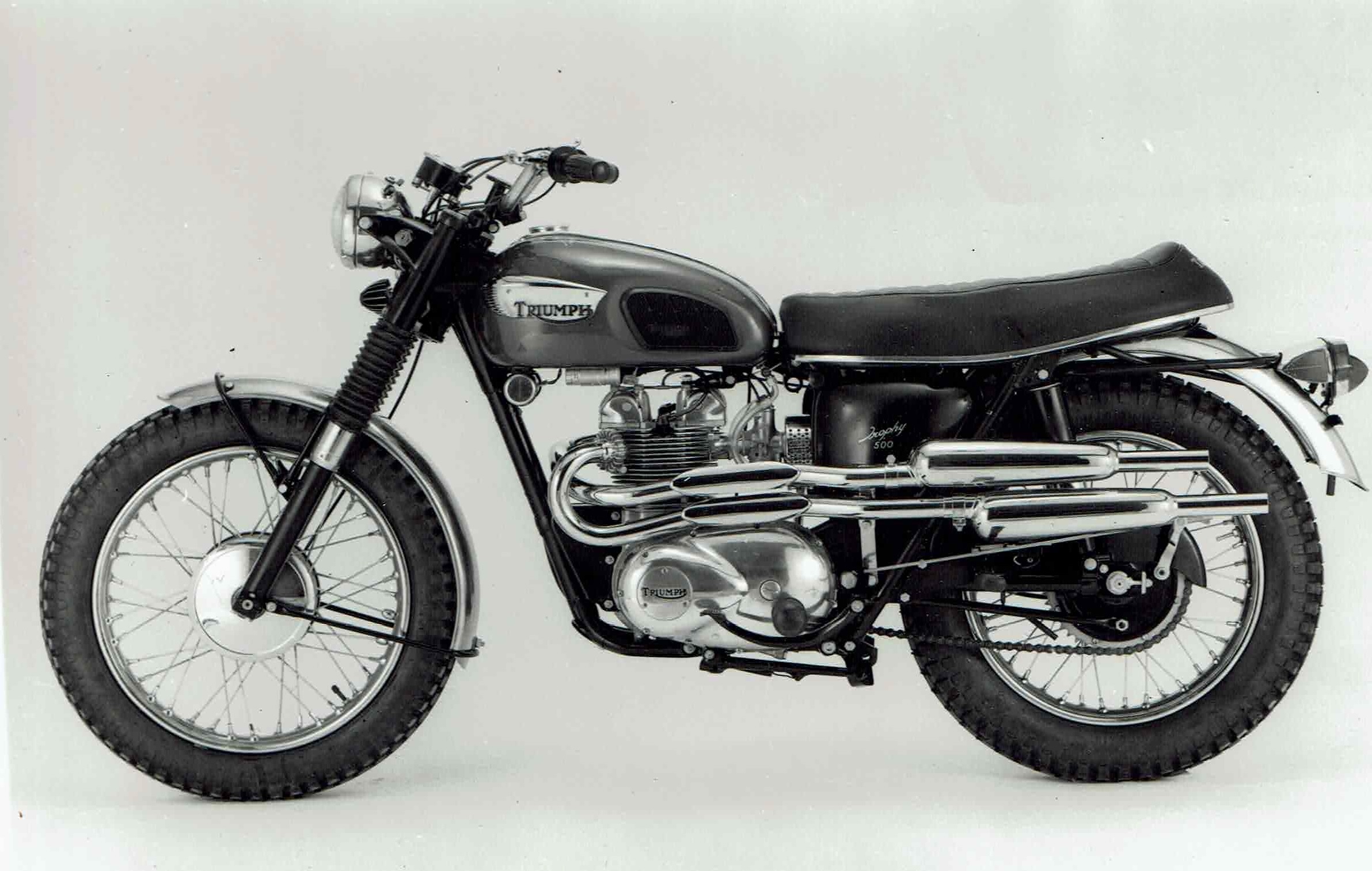

As the basic frame, engine, hubs, brakes, petrol tanks, oil tanks and suspension components remained in production for many years and other parts such as seats, mudguards, headlamps, exhausts and general components are available as relatively inexpensive pattern spares it is easy to create a replica of any of the later sports models from a T21 project bike at a reasonable cost. Buyers of projects should also consider replicas of the various ISDT, Trials, Dirt, Scrambler, Racing and Military models that Triumph built from the same basic components that made up the varied ‘C’ Range Twins. Continue to scroll down or use the tabs to take you to the other sections of the site.

1958

Engine Frame Numbers H761-H5480

| Models Covered | Standard |

|---|---|

| 1958 Triumph T21 | 4720 |

| 1958 Triumph 3TA | 2 |

| 1958 Triumph 5TA | 2 |

Sales for all Triumph Models for 1958

| 1958 | T20 | T20c | T21 | 5T | TR5 | T100 | TRW | 6T | TR6 | T110 |

|---|---|---|---|---|---|---|---|---|---|---|

| Home | 5558 | 714 | 2374 | 592 | 37 | 627 | 1260 | 54 | 1394 | |

| Jomo | 189 | 508 | 275 | 10 | 30 | 10 | 125 | 812 | 180 | |

| Tri-Cor | 474 | 524 | 351 | 10 | 66 | 8 | 183 | 643 | 531 | |

| Export | 1699 | 171 | 1263 | 599 | 336 | 511 | 27 | 820 | 178 | 720 |

| 7920 | 1917 | 4263 | 1211 | 469 | 1156 | 27 | 2388 | 1687 | 2825 |

Total Sales for Triumph in 1958 is 23836 machines. 53% are Home Market, 21% USA and 26% Export Sales.

By the late 1950’s the output of British Motorcycle Manufacturers is falling from its peak of 187,000 in 1954. In 1958 Honda build 285,000 Machines!

Triumphs are extremely popular in America, out selling most other makes with distribution of machines and parts handled by Johnson Motors and Tri-Cor.

Jomo or Johnson Motors, formed by Bill Johnson and Wilbur Cedar in 1938 in Pasadena, distribute complete machines and parts to 150 dealers in the 19 western states including Texas, Oklahoma, Kansas, Nebraska and North and South Dakota with California being the main location for motorcycle sales.

Tri-Cor in Baltimore begun in 1949 as a wholly owned subsidiary of Triumph Engineering is the distribution hub for hundreds of dealers spread across the eastern United States from the Canadian border to Key West in Florida.

For more information and images look for Lindsay Brooke and David Gaylin’s excellent “Triumph Motorcycles in America”

Many of the details for the 1957 T21 apply for the 1958 model.

For 1958 there is a new frame with revised steering angle (possibly 67 degrees) and a new ‘Stressed’ petrol tank, now showing the raised central seam covered by the chrome trim, with the addition of the parcel grid on the tank top. This new tank is ‘Stressed’ by the inclusion of a squared beam running longitudinally between the fixing points, the top of the beam is visible through the fuel cap aperture.

The front brake hub is now painted black and on the offside is shown a fluted chrome cover, this only applies for 1958!

For 1958 there are new Silencers, now asymmetric with the exhaust pipe entering lower down and therefore raising the silencer slightly, the brackets to attach the silencers to the machine and to support the pillion footrests change to an improved shape which now becomes standard for the model until 1963.

The Mainstand is now the ‘Easylift’ stand indicated in the 1958 brochure and displayed in the 1959 brochure.

After H3330 the carb size changes to 25/32 inch, now with the plunger choke fitted though this is likely to have been added earlier in production.

The Dualseat illustrated in the 1958 catalogue (above image) shows the seat strap but this is inaccurate on UK machines, it may remain on some export machines.

From July 1958 the method of securing the battery changes to the later form where a rod passes across the battery holding this in place.

1958 T21 machines will be finished overall in Blue Sheen with Black Frames and ancillary parts including hubs. Cylinder fins are generally Silver Sheen.

Parts Book No: 1

Notes for 1958

This is a summary of the engine modifications made during 1958 and the models that they apply to/from, these details are taken from the Factory Engine Build Records

H1584 Modified Valve Springs Fitted from here

H2297 Primary Chaincase Metering Jet Reduced (This is a mystery to me as I was not aware there was one!)

H2458 Modified Big End Bolt (Shorter) fitted from here

H2769 Battery Securing Method Changes.

H2828 First engine fitted with endless chain (primary drive)

H3663 Longer Distributor Clamp Bolt fitted

H4184 New Pattern Tappets Fitted from this number

H5169 New Clutch inserts on all machines (Neolangite)

H5015 Modified Bottom Seal on the push rod tubes

A Tri-Cor Bulletin of 10th January 1958 describes a Plastic Battery Cover that should be fitted before the machine is sold and to not overfill the battery.

This probably covers machines before H2769 when the Battery Tray is changed to eliminate the earlier issues of acid vapours causing corrosion.

Production for 1958 begins on the 10th September 1957 with H761 sent to Hacks Cycle Store, British Guiana on the 20th September

The first UK machine is H774 sent to F.H. Blackpool and Co Ltd, Stanstead Road, Forest Hill, London on the 18th September.

Only 637 machines are sent to the USA with approximately equal numbers to Johnson Motors and Tri-Cor.

33 T21 machines are supplied to UNICEF (Kenya), a picture is available in the BSA Group News Centenary booklet, this rare and fascinating book can be viewed at the VMCC Library in Burton on Trent (Open to Members of the VMCC)

The 1958 brochure shows the under seat area of a T21, I have identified this machine as H120 as the image is taken from the publicity shots of this machine and therefore does not actually represent a 1958 model !

I have in my photo collection a number of images of T21’s taken at the factory in September 1957, kindly provided by Mike Estall of Tiger Cub Fame.

There are no UK road tests on the model in 1958 but look for “The Motorcycle” of 24th October 1957 for an article on the Improvements to the Triumph Range for 1958. These annual improvements are generally announced in the press at about the time of the Earls Court Show and are a valuable source of information for restorers.

The article also includes an exploded diagram of the T21 Engine, a description and picture of the crankshaft, details of the “Slickshift” featured on the larger models and images, specifications and prices.

Look for American Motorcycling of January 1958 for the release article and images. These show a black framed T21, one of only a handful dispatched in time for this publication.

In the 1958 ISDT (West Germany) Roy Peplow is riding for the Great Britain A Vase Team is on a 500cc Triumph this is in fact an earlier Triumph Trophy (UAC 534)

Look at the superb site www.speedtracktales.wordpress.com for details on the ISDT including many previously unpublished photographs.

The Barber Museum in Birmingham Alabama have an excellent restored example of a ‘21’ (H2158) along with several other Triumphs, the museum is a motorsport mecca housing a diverse collection of rare motorcycles and cars, well worth a trip, especially for the Barber festival in October.

List Price for the T21 from Sep 1st 1957 (1958 season) is £ 228/5s/11d

List price in the USA is $ 818

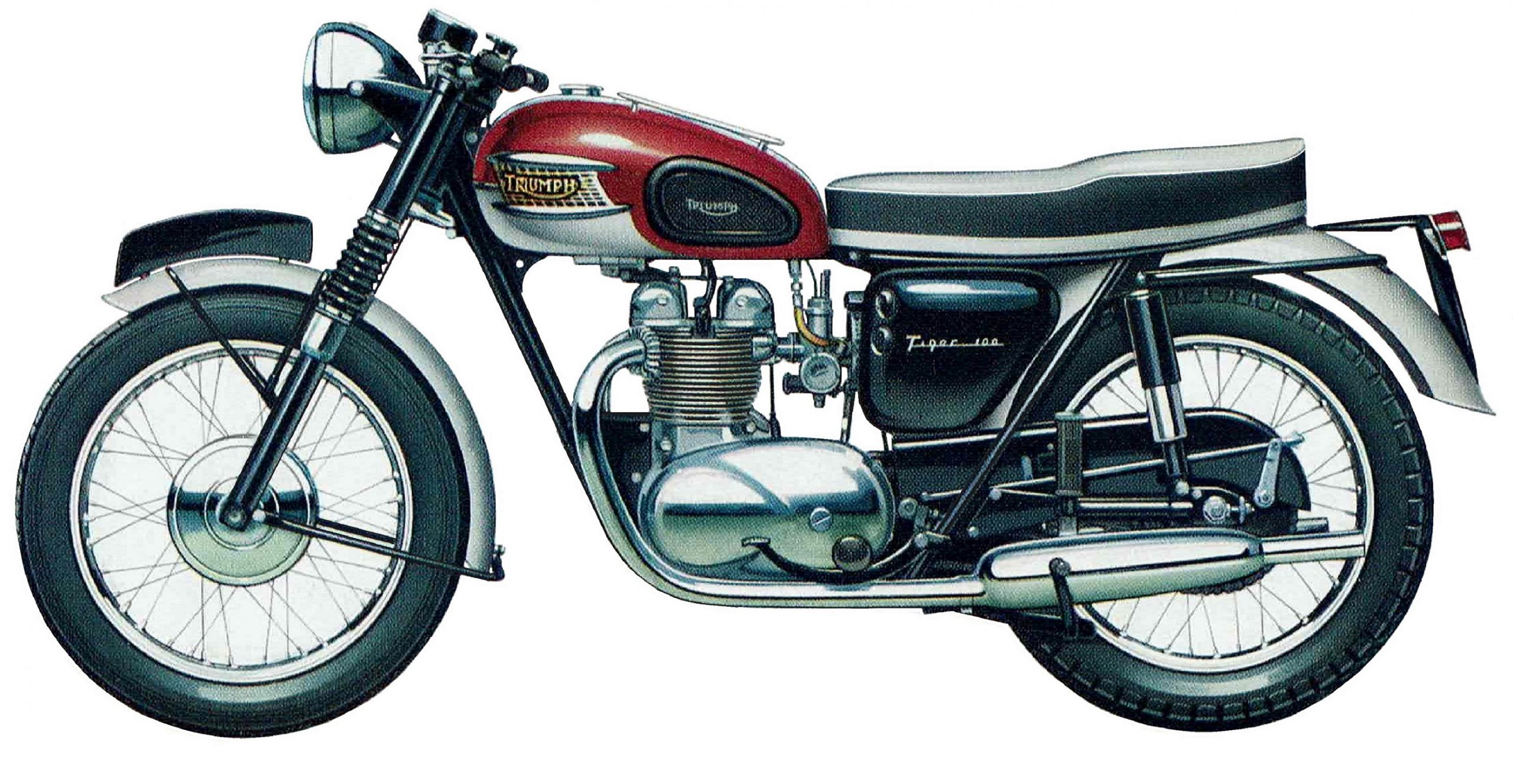

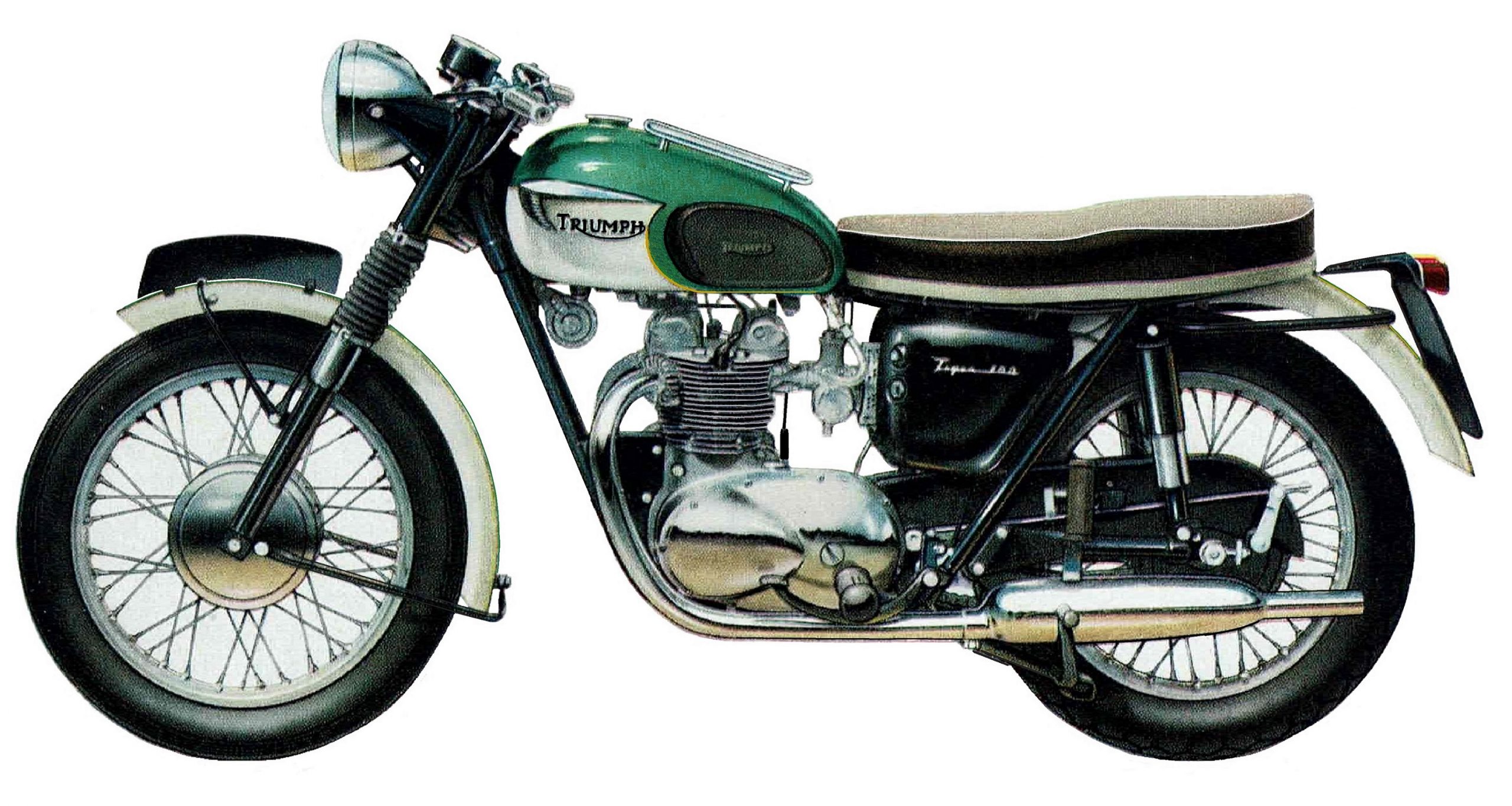

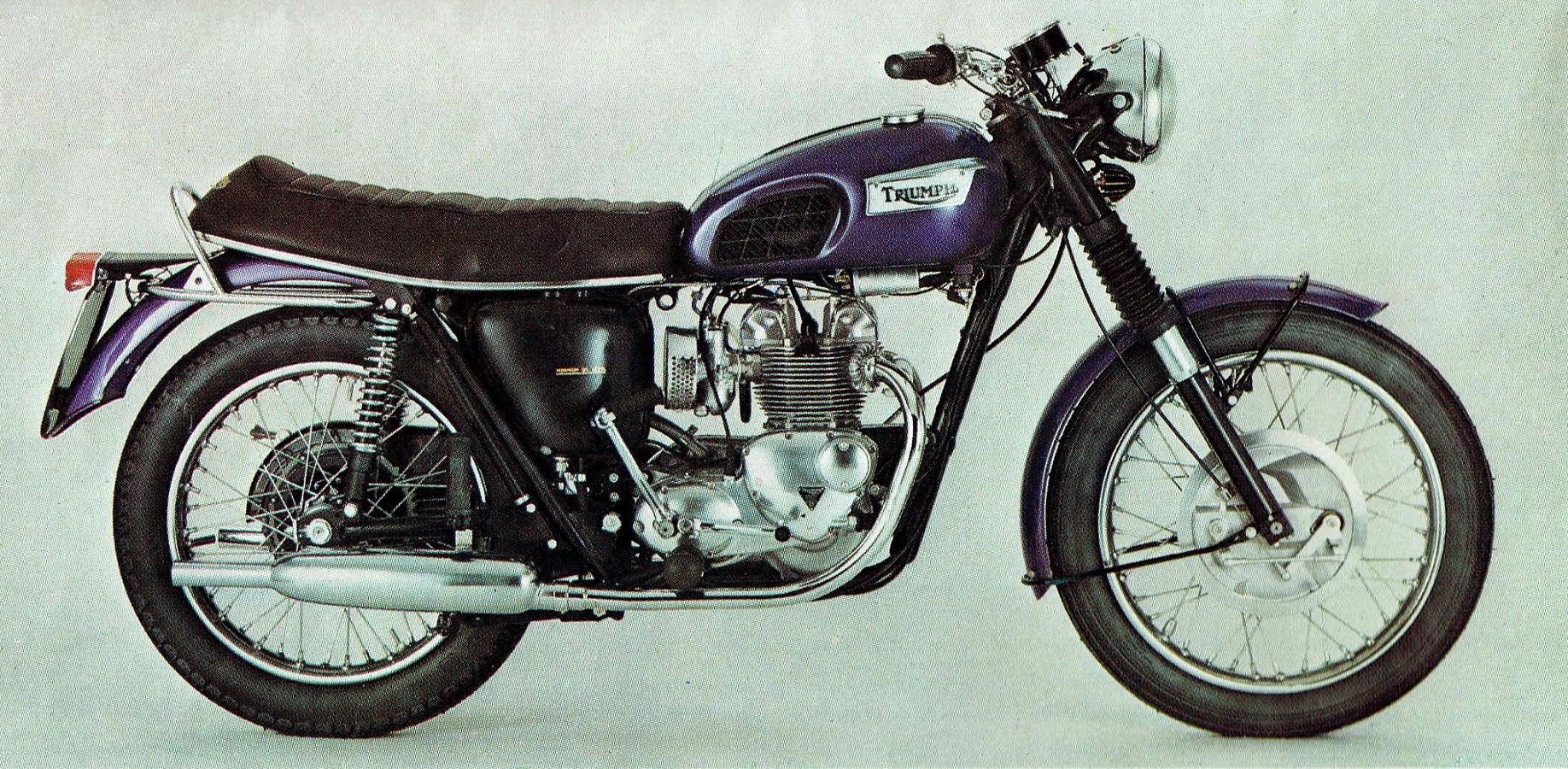

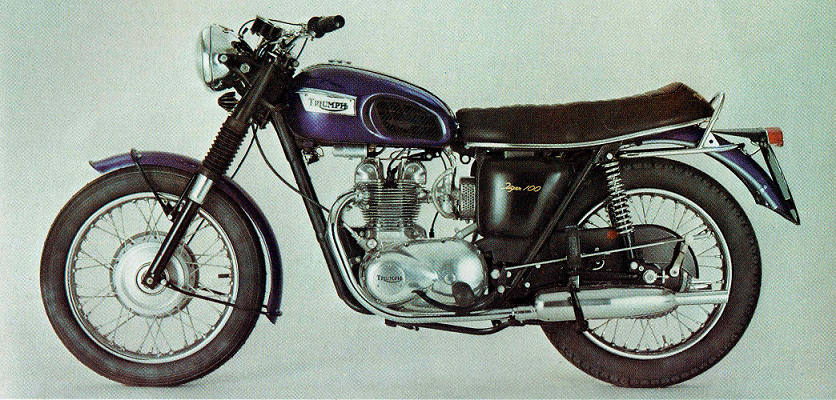

1959 5TA

1959

Engine Frame Numbers H5481-H11511.

| Models Covered | Standard | Police |

|---|---|---|

| 1959 Triumph T21 | 34 | |

| 1959 Triumph 3TA | 2802 | 59 |

| 1959 Triumph 5TA | 3112 | 18 |

| 1960 Triumph T100A | 2 | |

| 1960 Triumph TR5AR | 1 |

Sales for all Triumph Models for 1959

| 1959 | T20 | T20C | T20S | 3TA | 5T | 5TA | TR5 | T100 | TRW | 6T | TR6 | T110 | T120 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Home | 5868 | 307 | 169 | 2220 | 45 | 1867 | 1 | 514 | 1 | 1274 | 91 | 1821 | 271 |

| Jomo | 254 | 159 | 425 | 10 | 92 | 50 | 2 | 111 | 461 | 95 | 310 | ||

| Tri-Cor | 441 | 317 | 432 | 1 | 226 | 30 | 5 | 193 | 584 | 351 | 799 | ||

| Export | 1968 | 86 | 73 | 853 | 66 | 562 | 18 | 347 | 100 | 626 | 128 | 590 | 500 |

| 8531 | 869 | 1099 | 3084 | 111 | 2747 | 99 | 868 | 101 | 2204 | 1264 | 2857 | 1880 |

Note that the Sales figures do not represent how many of each model were built for that model year.

From the sales data you will note the failure of the 3TA in the US Market but strong sales into the UK

The accounting period is August 1st to July 31st with production for 1959 starting on the 18th September with quantities of 3TA’s and 5TA’s.

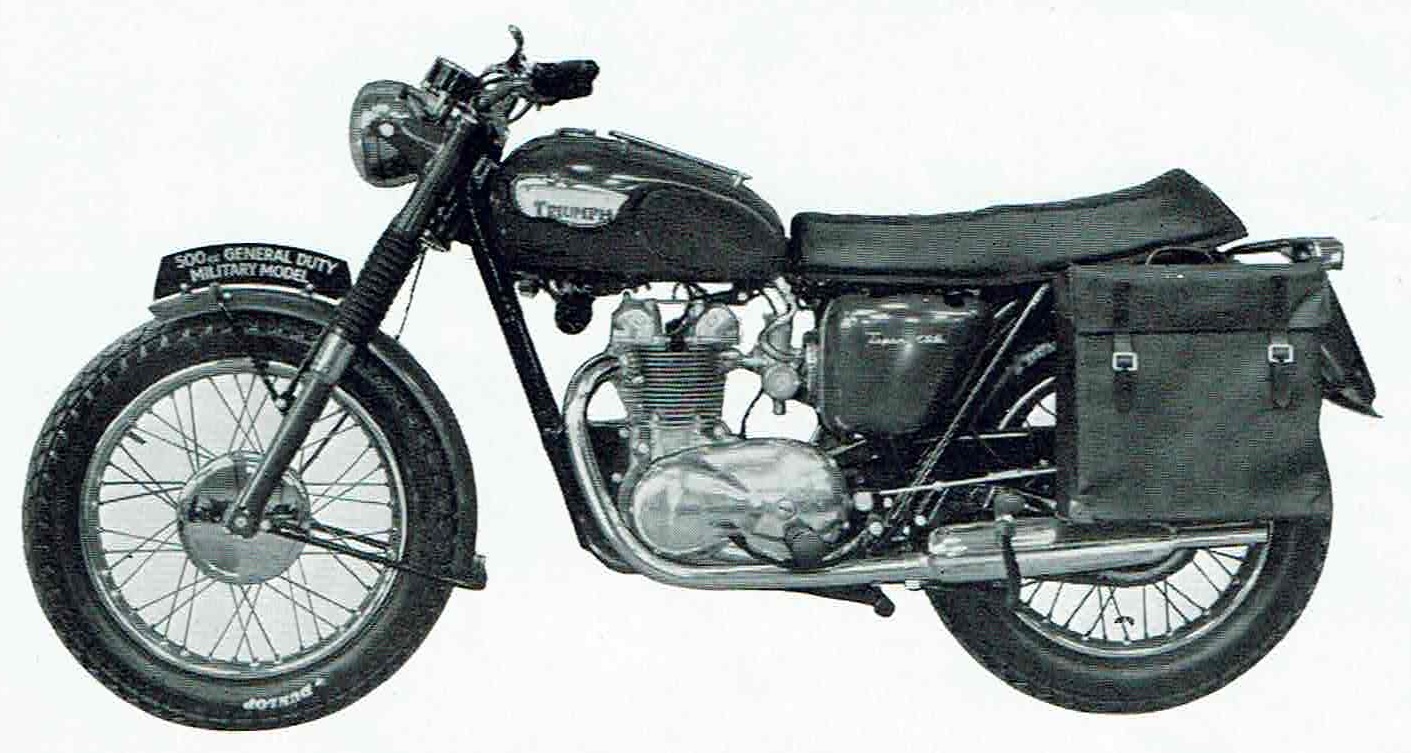

The engine number will be preceded by the model type to indicate the general specification. Machines were supplied to a variety of overseas customers and it is important to identify the original destination and user of your machine before commencing restoration. Machines supplied in batches to overseas governments would have been made to a particular specification often far removed from Home market (UK) machine specification.

Police machines indicated in the build and despatch records are for both UK and Export and feature detail differences from Standard Machines.

In the Factory Records it can be very difficult to identify machines built to non-standard specifications, to the casual observer without knowing which dealers dealt with Police orders for their county or municipal force these can be easily missed.

The 3TA for 1959 remains largely unchanged and remains popular in the Home market.

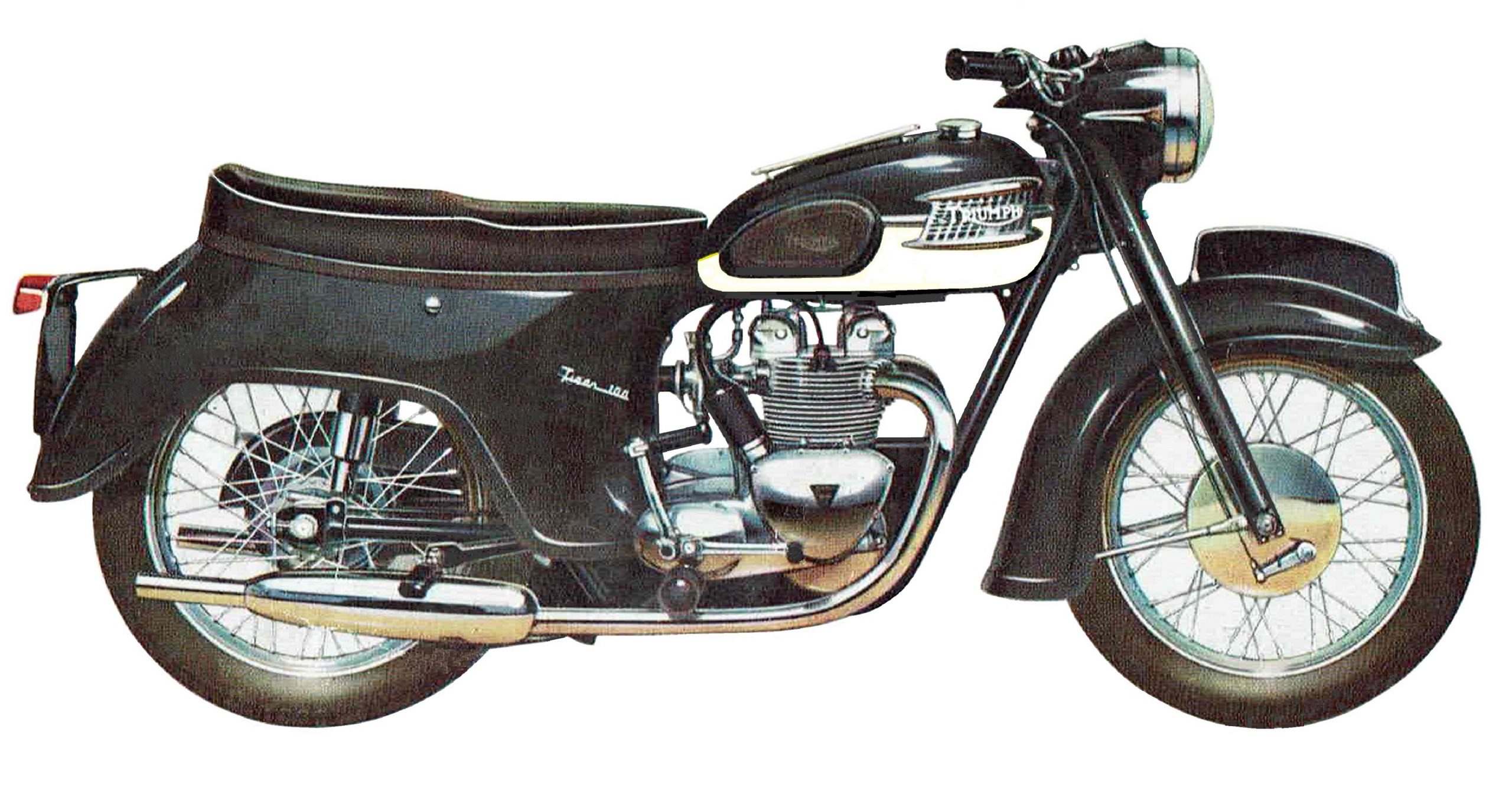

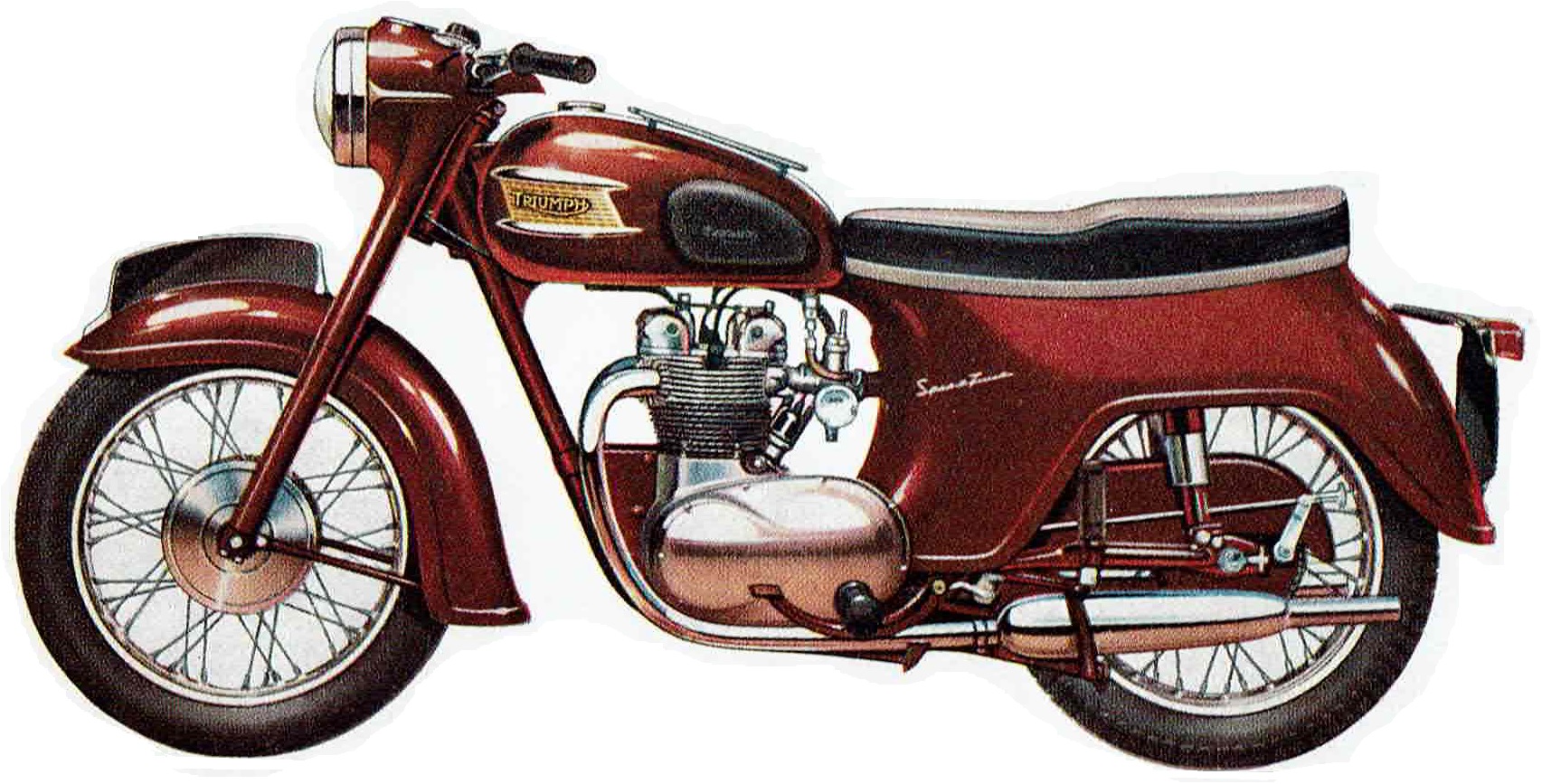

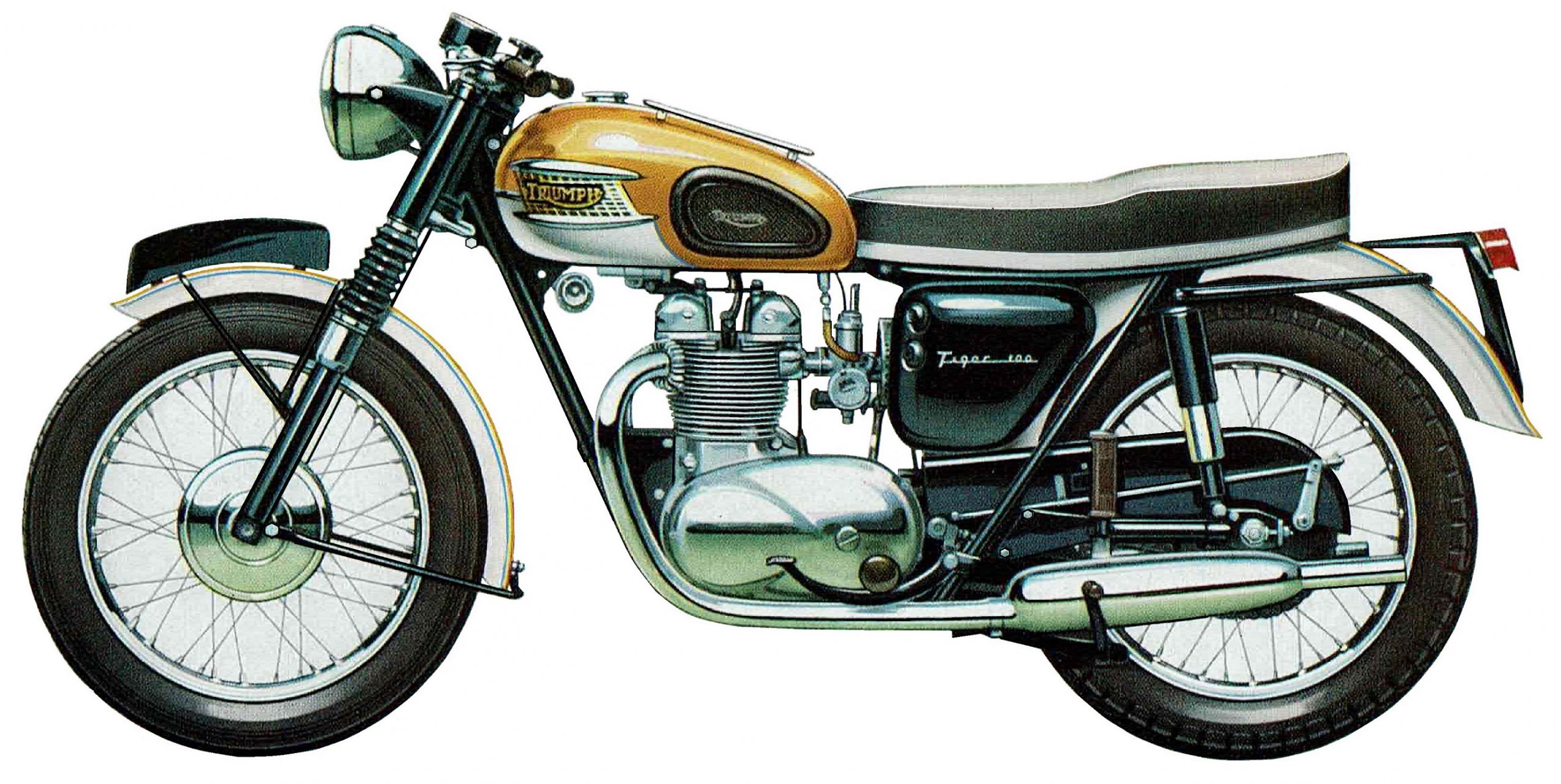

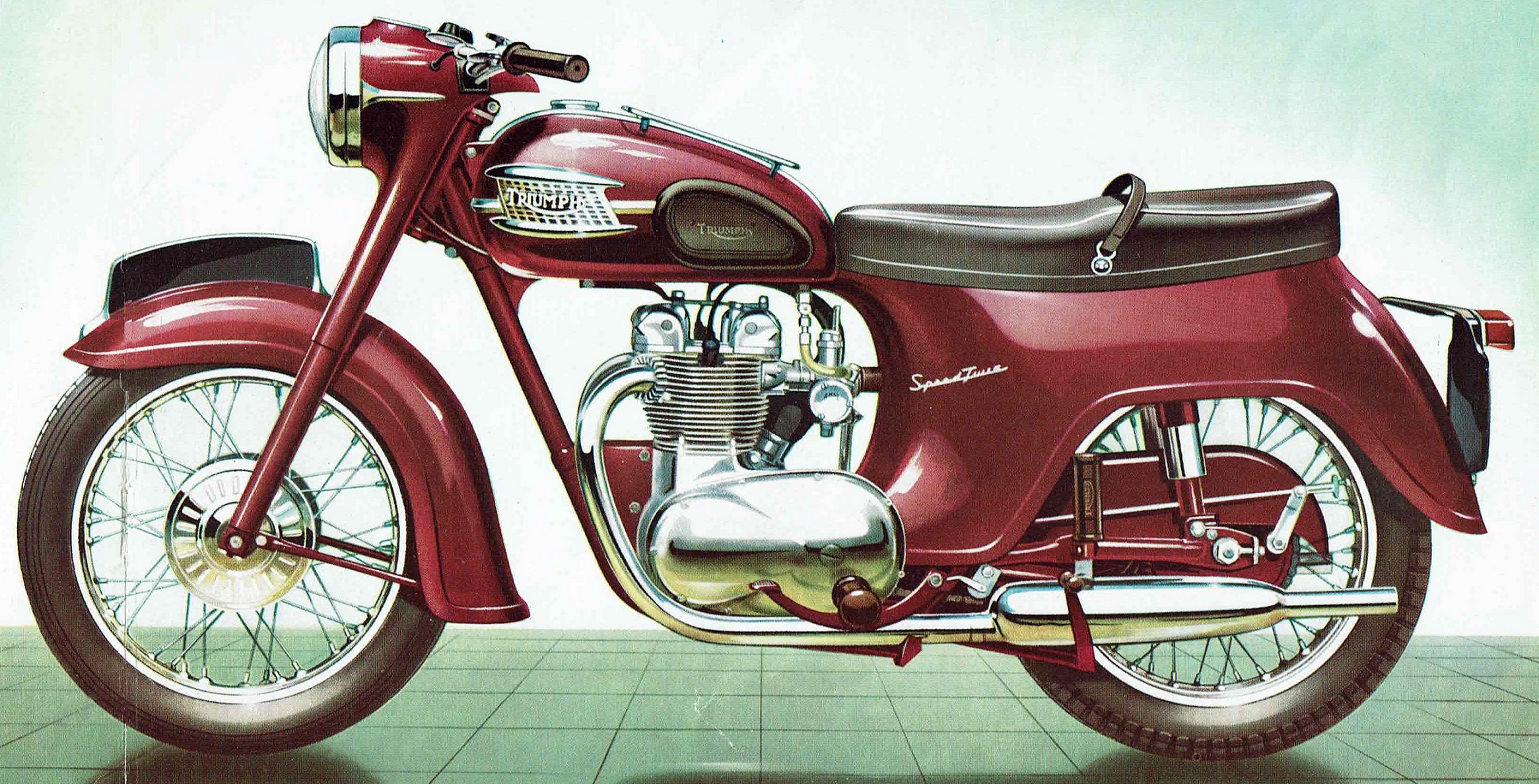

1959 sees the introduction of the 5TA, which replaces the earlier 5T, the ancestor of the famous Speed Twin of 1938

The crankshaft for the 3TA and 5TA are common but rather than the stamped steel conrods of the 3TA the 5TA uses Light Alloy H-Section rods. The stroke remains at 65.5 mm but the bore is increased to 69.0 mm to give the new capacity of 490cc and fitted with 7:1 pistons the performance improves to 27 b.h.p at 6,500 r.p.m.

The 5TA has a 20 tooth gearbox sprocket in place of the 18 tooth one of the 3TA/21. Both machines have the same gearbox internal ratios but the 20 tooth sprocket raises the overall ratios to 11.56,8.35,5.62 & 4.8 to 1.

The 5TA also features a slightly larger 375/3 (7/8inch) Amal Monoblock Carb.

The 5TA features an increase in rear tyre width to 3.5 inches while the T21/3TA retains the 3.25 Tyre Size as before..

For both models a revised method of attaching the air filter is used, illustrated in the “The Motor Cycle” of 23rd Oct 1958. This allows the filter to be extracted through the seat opening rather than removing the left hand Bathtub Panel. Also shown in the illustration is the Plunger for the Choke, the clear petrol pipe with ferrule and the distributor clamp.

The modifications feature in “The Motorcycle” indicates that the front brake cam lever is altered to improve the action and that plain chrome covers on the hub replace the fluted covers fitted for 1958, even though the brochure image above shows the fluted cover!

So far No 3TA or 5TA machines have been fitted with the QD rear hub and it is not listed in the optional extras which remain advertised as Prop Stand and Pillion Footrests.

Colours for 1959 are …

3TA Shell Blue Sheen, Black Frame, Silver Sheen Front Hub and Cylinder Fins

5TA Amaranth Red Overall including the Hubs and rear brake drum. Black Cylinder fins

US brochures describe the colours as Azure Blue and Continental Red.

A few machines are supplied in other Colours, 3TA’s H8945 and H8946 are supplied to the Ministry of Supply London. H8946 in Charcoal Finish !

Other machines supplied to the Police or in batches to foreign governments such as Vietnam may be in an alternative scheme.

Parts Book No: 2 this starts from H5485! Like the earlier parts book not all the parts are illustrated.

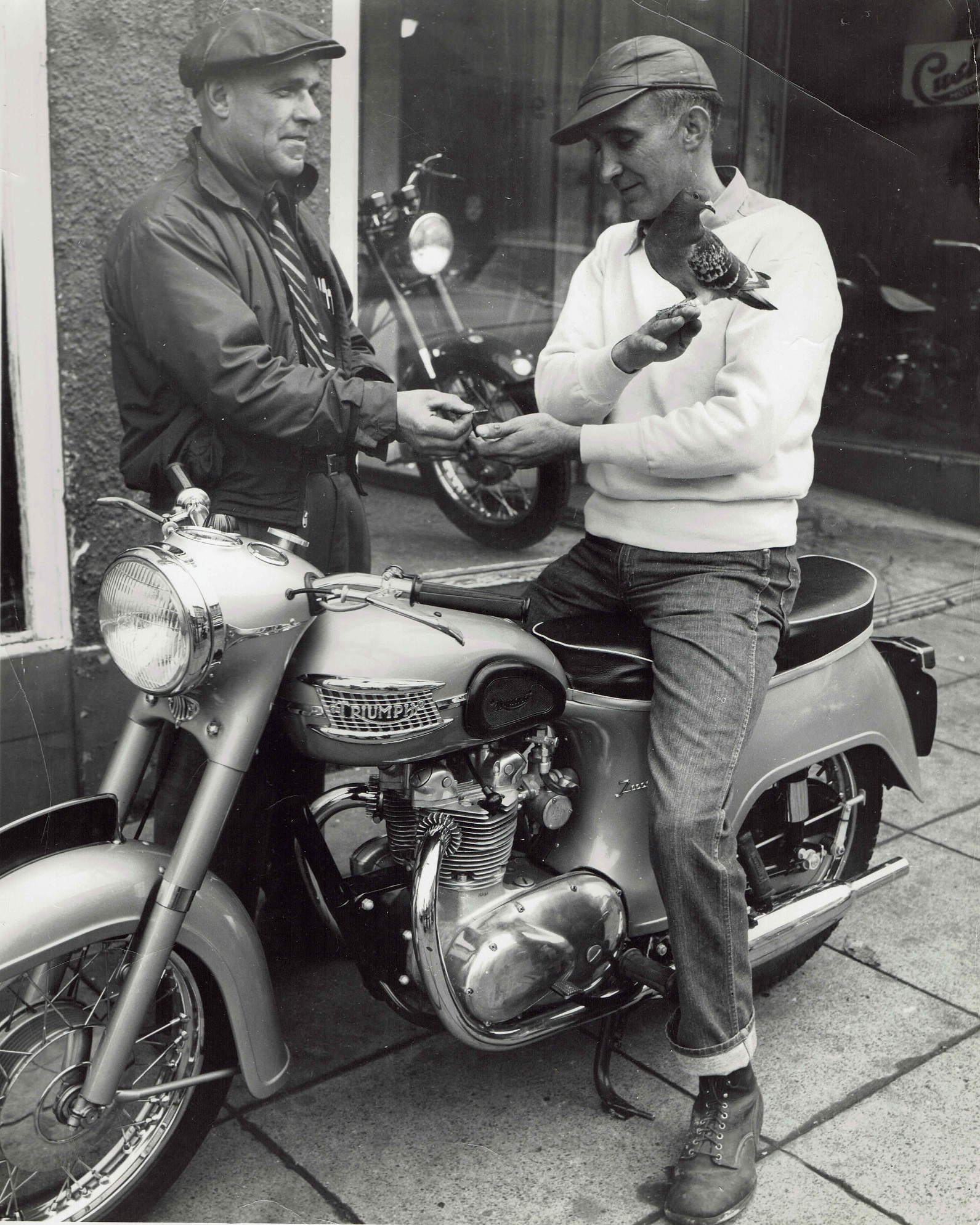

From my collection of original Triumph Publicity photographs.

Notes for 1959

| 1948 | % | 1949 | % | 1950 | % | 1951 | % | 1952 | % | 1953 | % | 1954 | % | 1955 | % | 1956 | % | 1957 | % | 1958 | % | 1959 | % | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Australia | 18880 | 46% | 25107 | 61% | 22171 | 44% | 24180 | 41% | 6872 | 21% | 6678 | 20% | 9474 | 22% | 6692 | 20% | 3923 | 13% | 4490 | 16% | 2271 | 11% | 1921 | 9% |

| New Zealand | 924 | 2% | 1787 | 4% | 2235 | 4% | 5600 | 9% | 3186 | 10% | 2168 | 6% | 3140 | 7% | 1371 | 4% | 705 | 2% | 1264 | 5% | 756 | 4% | 614 | 3% |

| South Africa | 2907 | 7% | 1234 | 3% | 1282 | 3% | 2054 | 3% | 1885 | 6% | 1843 | 5% | 1957 | 4% | 2334 | 7% | 2418 | 8% | 2606 | 10% | 1456 | 7% | 843 | 4% |

| India / Pakistan | 3258 | 8% | 552 | 1% | 1625 | 3% | 3511 | 6% | 3413 | 10% | 1849 | 5% | 4565 | 10% | 3325 | 10% | 2247 | 7% | 2357 | 9% | 2784 | 13% | 3136 | 14% |

| U.S.A | 8178 | 20% | 4267 | 10% | 8582 | 17% | 8195 | 14% | 7075 | 21% | 5136 | 15% | 8172 | 19% | 9598 | 29% | 13651 | 44% | 12383 | 45% | 10601 | 51% | 12834 | 58% |

| Canada | 3790 | 9% | 5404 | 13% | 6225 | 12% | 3326 | 6% | 1047 | 3% | 2062 | 6% | 1595 | 4% | 1196 | 4% | 2562 | 8% | 1411 | 5% | 1228 | 6% | 1387 | 6% |

| Denmark | 321 | 1% | 591 | 1% | 480 | 1% | 505 | 1% | 1325 | 4% | 5641 | 16% | 4040 | 9% | 1537 | 5% | 584 | 2% | 338 | 1% | 114 | 1% | 180 | 1% |

| Sweden | 804 | 2% | 299 | 1% | 3653 | 7% | 5283 | 9% | 4340 | 13% | 5762 | 17% | 5689 | 13% | 2086 | 6% | 643 | 2% | 813 | 3% | 693 | 3% | 423 | 2% |

| France | 587 | 1% | 150 | 0% | 1907 | 4% | 5015 | 8% | 3117 | 9% | 3044 | 9% | 2539 | 6% | 2358 | 7% | 2662 | 9% | 963 | 4% | 695 | 3% | 658 | 3% |

| Netherlands | 1495 | 4% | 1468 | 4% | 2097 | 4% | 1899 | 3% | 1171 | 4% | 43 | 0% | 2552 | 6% | 2240 | 7% | 1725 | 6% | 799 | 3% | 343 | 2% | 320 | 1% |

| Ireland | 1101 | 3% | 586 | 1% | 1206 | 2% | 1291 | 2% | 1211 | 4% | 3003 | 9% | 3266 | 7% | 3365 | 10% | 2052 | 7% | 1151 | 4% | 1322 | 6% | 3383 | 15% |

| Total | 41144 | 40859 | 50257 | 59568 | 33431 | 34226 | 43723 | 32737 | 31120 | 27424 | 20941 | 22316 |

The table above gives an overall view of all British Motorcycle Exports to 1959 and has been compiled from information taken from a Daily Mail publication, one of a series of data books produced until the early 1960’s that contain interesting details for any motorcycle historian.

The figures above do not include the buoyant home market, at the peak in 1954 the British factories build 187,000 motorcycles! From above you will note the changing fortunes of each market and the increasing importance of the USA which is reflected in Triumph’s sales figures shown elsewhere. These figures represent the whole of the British Motorcycle Industry and the numerous manufactures and products that they are producing. By the mid-sixties many of these companies have gone or been absorbed and motorcycles begin the change from being predominately forms of transport to a means of leisure.

This is a summary of the engine modifications made during 1959 and the models that they apply to/from, these details are taken from the Factory Engine Build Records

H5785 Modified Kick Starter Shaft Bush from here

H7039 Shorter Valve Guides Fitted from here

H7116 All subsequent 5TA’s now have Tapered Piston Rings

H8141 Modified Tappet Guide Blocks to improve sealing of the Push Rod Covers

H8141 Thicker Push Rod Cover Seals from here

H9001 New Alternator Grommet

H10049 Modified Distributor Oil Seal

Production for 1959 begins on the 17th September 1958 with show models for the Paris Show (3rd Oct 58) and the Earls Court Show (Nov 15th-22nd)

3TA H5481 is eventually sent to Nigeria (10th December)

3TA H5482 is sent to Decat of Belgium on the 6th December

5TA H5483 is sent to Campbell & Cameron

5TA H5484 is sent to F. Llewellyn & Co Ltd, Liverpool on 18th Dec 1959

5TA H6187 is sent to The Daimler Company, Coventry for a Mr Hopper on the 18th Feb 59

One of the 5TA’s is shown at Earls Court fitted with a Radio in the Tank Top I believe that this is H5484.

The first Production 3TA for 1959 is H5485 sent to Kingston Motors, Kingston on Thames

The first Production 5TA for 1959 is H5785 sent to Julius Martinez, Nicaragua as part of a batch of 23 machines.

H5881 is a 5TA built by the experimental dept, eventually dispatched to J Surtees on 23rd Oct 59

H5939 is a 5TA possibly a press machine or factory machine eventually dispatched to Slocombes of Neasden (3rd Oct 1960)

H6549 is possibly the first Police Specification 3TA, supplied to the Bucks Constabulary on 21st November 1958.

H6550 is also a Police Specification machine but is retained until March 1959 when it is sent to Surtees, West Wickham.

H8656 appears to be the First Police Specification 5TA supplied to Hadlers of Chelmsford followed later by H8900

3TA’s H8945 and H8946 are supplied to the Ministry of Supply, London. H8946 is in a Charcoal Finish !

H6159 is a 5TA which is converted to a TR5AC by the competition department, this machine is registered to the Factory as 565 AAC.

H6282 is an engine taken from a 3TA production batch on the 12th November 1958 and transferred to the Experimental Department for conversion to a T100A.

This machine is sent to Slocombes of Neasden on the 16th November 1959.

H9480 the T100A production prototype is a taken from a batch of 5TA’s on the 22nd May 1959 and built for the Experimental Dept with high compression pistons.

Two sets of photographs of this machine survive in the VMCC archive, one with the machine finished in Blue or Silver Sheen (unregistered) and the other set with the machine in Black over Ivory (registered 148 AUE), see next section. Also see the road test in “Motor Cycling” March 10th 1960 featuring this machine.

Both sets of photographs clearly show the engine stamped as 5TA H9480, it later is sent to Jack Surtees, West Wickham on the 8th July 1960

The whereabouts of this interesting machine is as yet unknown, one to look out for …

A photograph of this machine is in the 1960 Section.

H5886 appears to be the first 5TA sent to the USA (Tri-Cor) part of a batch of 50 with H5934 a single 5TA from this production batch to Johnson Motors

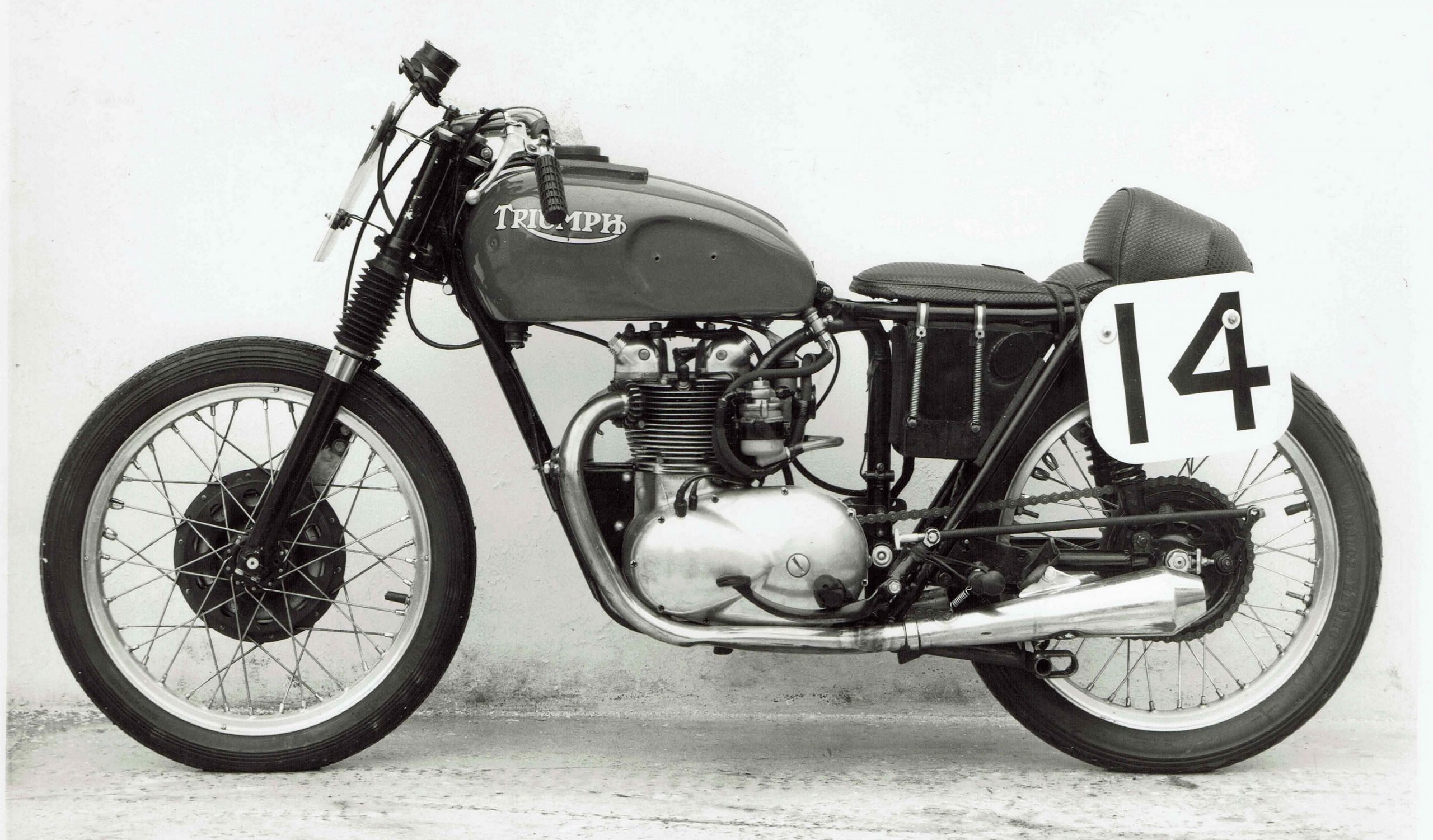

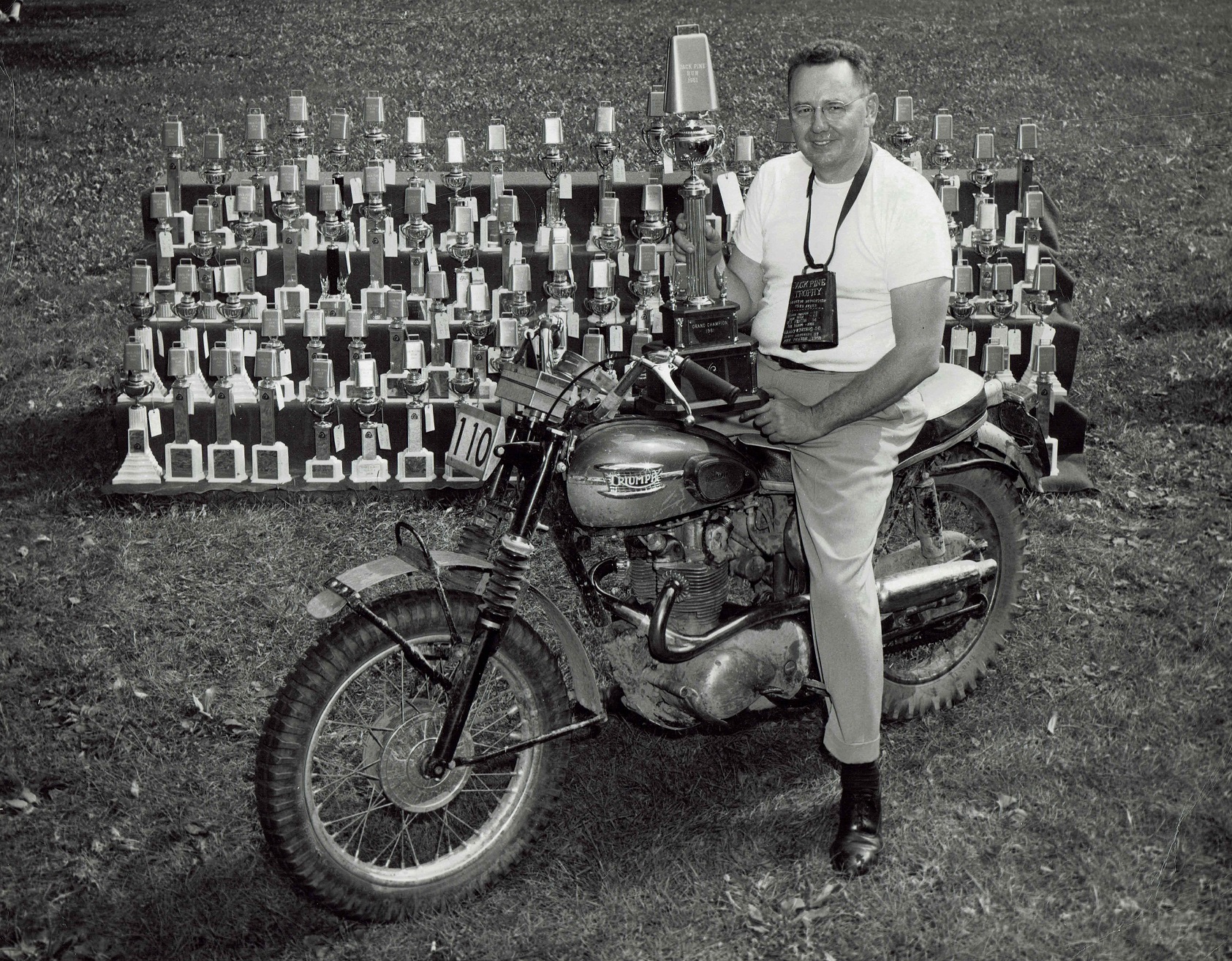

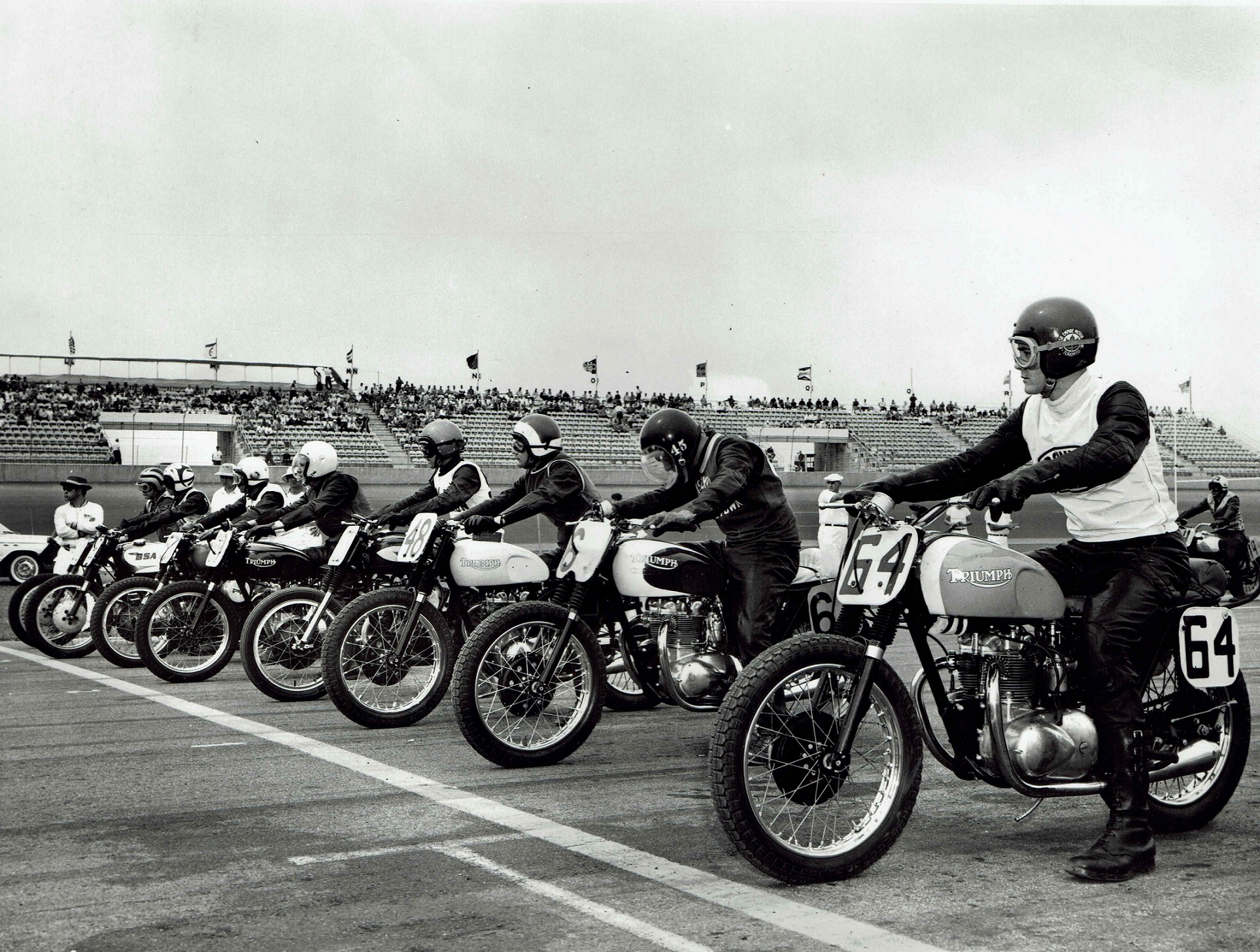

From my collection of Tri-Cor Bulletins and articles is a Brochure Sheet describing converting the 5TA to an AMA Class “C” Racer, this sheet details the soon to be available “Race Kit” and gives comprehensive details of the modifications required and parts needed for Class “C” Road Racing and Class “C” Dirt Track Racing. Included are Photographs of Two Machines, see above.

At Daytona a modified 5TA ridden by Ralph Tysor from Charlotte NC puts in the second fastest qualifying time at a speed of 120 mph, there is a picture of the machine and rider in Motor Cycle News of Wednesday March 18th 1959

If you have a 5TA Project Bike, you could consider these specifications as an option to an original restoration. If you have found a 5TA in the USA carefully assess the engine specification as your machine may have been converted into one of these exciting machines.

Two machines are reported to have been entered for the National Championships at Laconia in June 1959.

Riders on Triumphs at the one mile Laconia circuit are Jimmie O’Dell and Sammy Tanner, finishing 13th and 19th respectively,

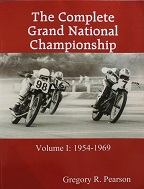

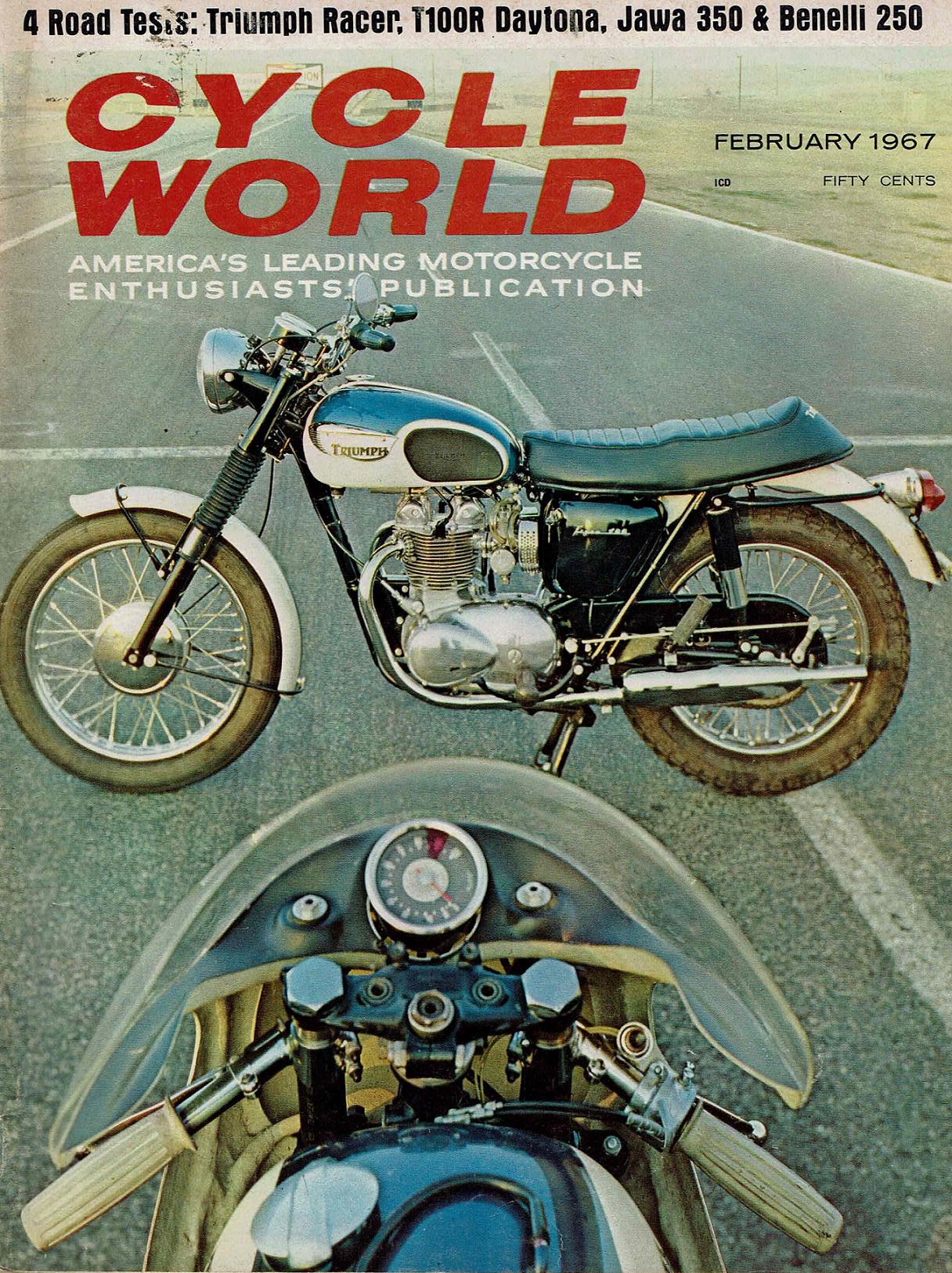

For more information look for “The Complete Grand National Championship Volume 1” by Gregory R Pearson. This excellent work contains the results lists for all the Grand National Championship races from 1954 to 1969 with numerous photos and anecdotes. A must have book for fans of the USA race scene.

A good source of period photographs, advertisements and event reports will be found in copies of American Motorcycling, now available on-line and searchable.

Also look for copies of Cycle and Cycle World, for a small subscription these can be viewed and enjoyed.

An early production 1959 5TA was entered in the 1959 Thruxton 500, coming seventh in the unlimited multi-cylindered event, the machine is used in other production bike events at Silverstone and Snetterton before being converted by Cyril Jones to a track bike in 1962. See the article in Motorcycle Mechanics September 1965.

The interesting modification on this machine is the swing arm to frame support as used on the later Daytona bikes and 1967 production machines.

1959 Production ends on the 4th September 1959 with H11511 a 3TA sent to Austria (part of a group of six)

Exports for this year are to varying locations as usual but relatively few machines are sent to the USA.

3TA machines (H6237 & H6557-H6585) and 5TA machines (H6938 & H6955-H7088) are sent to Aziz, South Vietnam. One Survives in the UK!

New export markets recently opened by Triumph are South Vietnam and Peru; 30 Twenty-Ones for the Vietnamese Customs service and 137 Speed Twins for other departments. The Peru Dispatch was for 30 Speed twins to be used by the Police in Lima, the capital. 100 TRW’s are going to Pakistan, which means that the Pakistan army now has nearly 1000 Triumphs in service. A repeat order is from Jamaica for 21 Speed twins to replace earlier models used by the police. Motor Cycle 26th Feb 1959.

For Illustrations of the 5TA you will need the “Motor Cycle” Road Test of 15th January 1959 and 14th May 1959,

both featuring 698 AAC (H6782)

Also look for Harry Woolridge’s excellent book on the Speed Twin which covers in detail the development history of the model from 1938 to its demise in 1966.

ISBN 0-85429-722-7.

The 14th May 1959 Cover of the “Motor Cycle” as described above.

There is a 1959 road test of a 3TA with excellent photographs available in the 30th April copy of “Motor Cycling”, this features 914 AAC.

I have yet to identify the Engine number of this machine.

Also look up images of Kwame Nkrumah’s Motorcade. Ghana 1959 which features a number of 3TA’s.

To find the 1959 Road Tests for all Triumph models use the “Magazine Articles” Tab at the top of the page.

Prices for the 1959 season are …

3TA £ 228/5s/11d

5TA £ 245/15s/2d

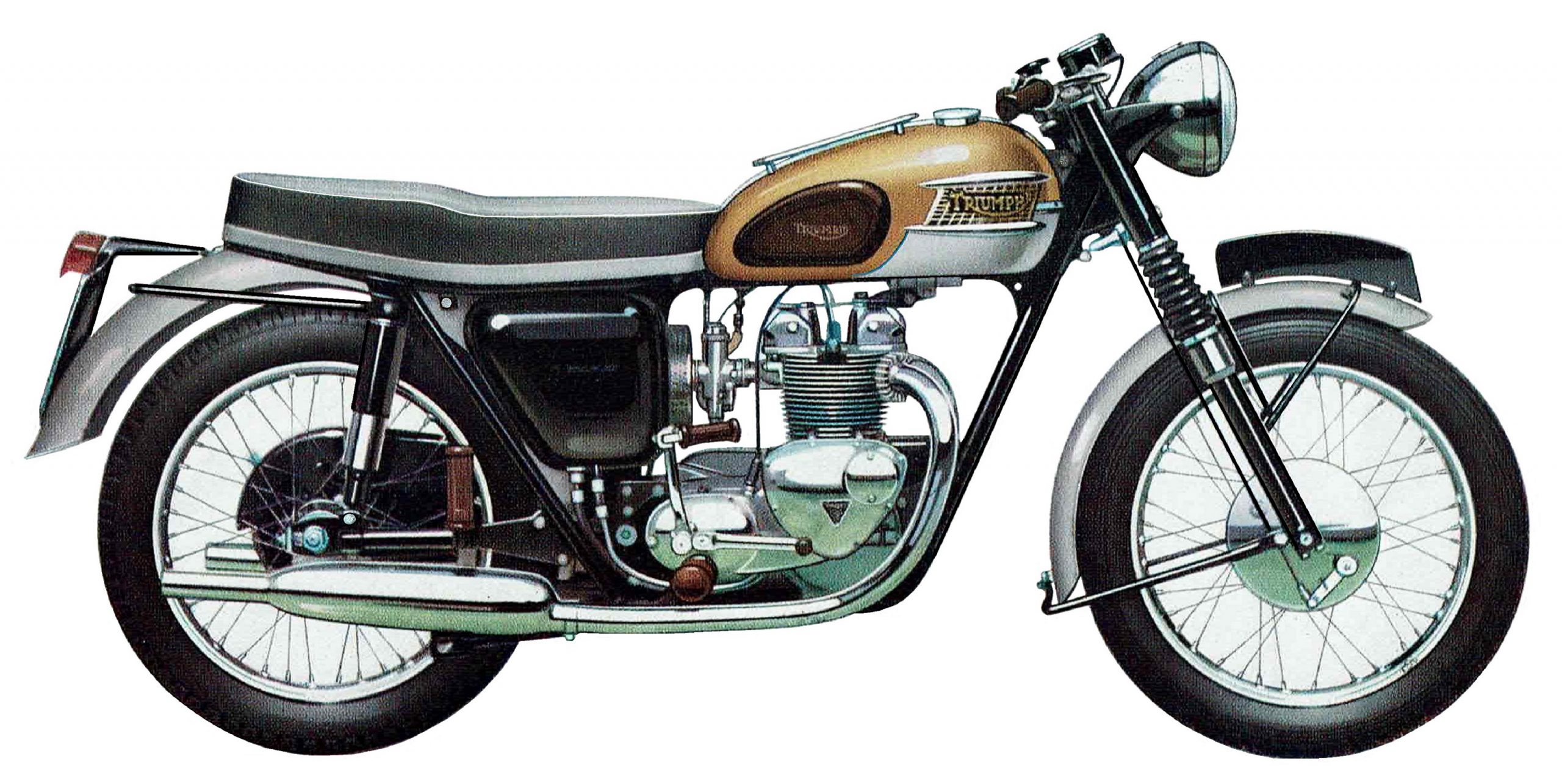

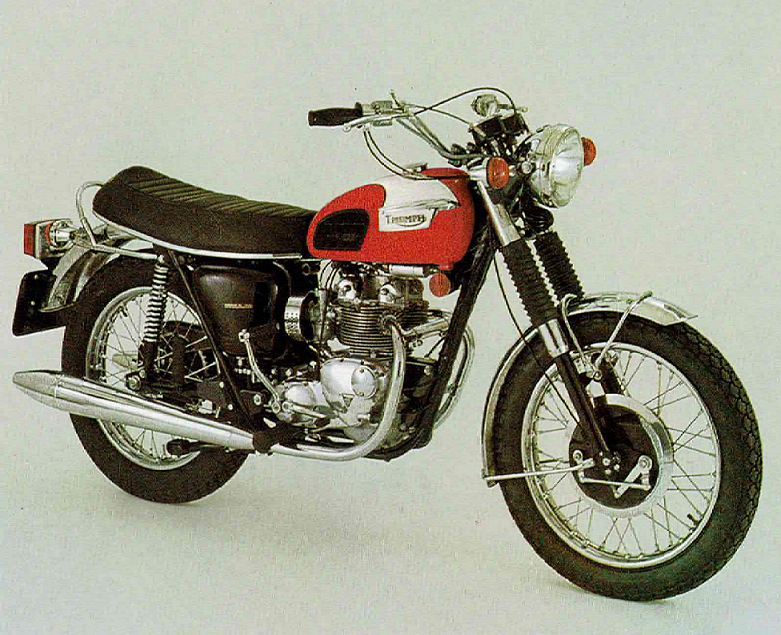

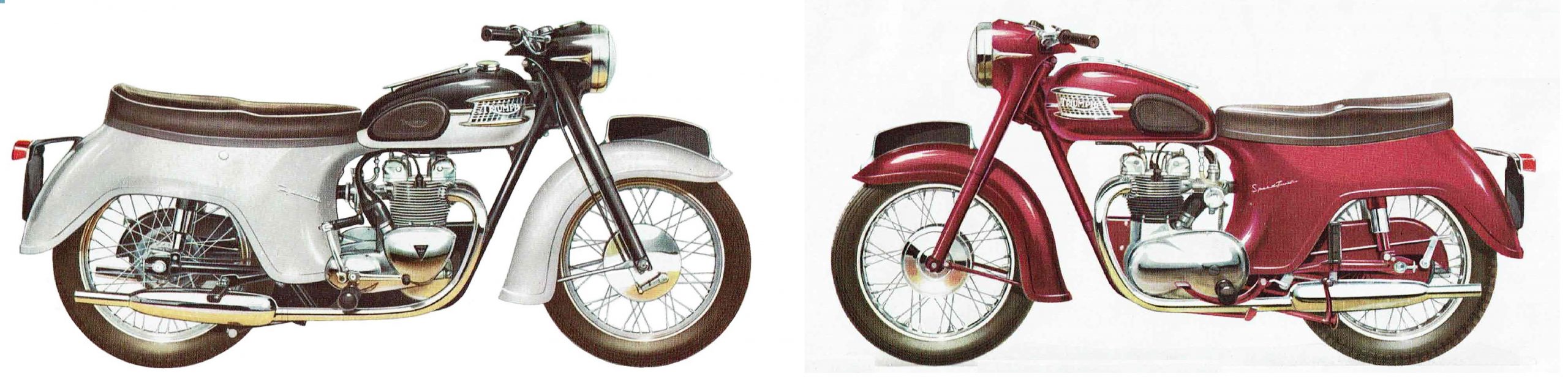

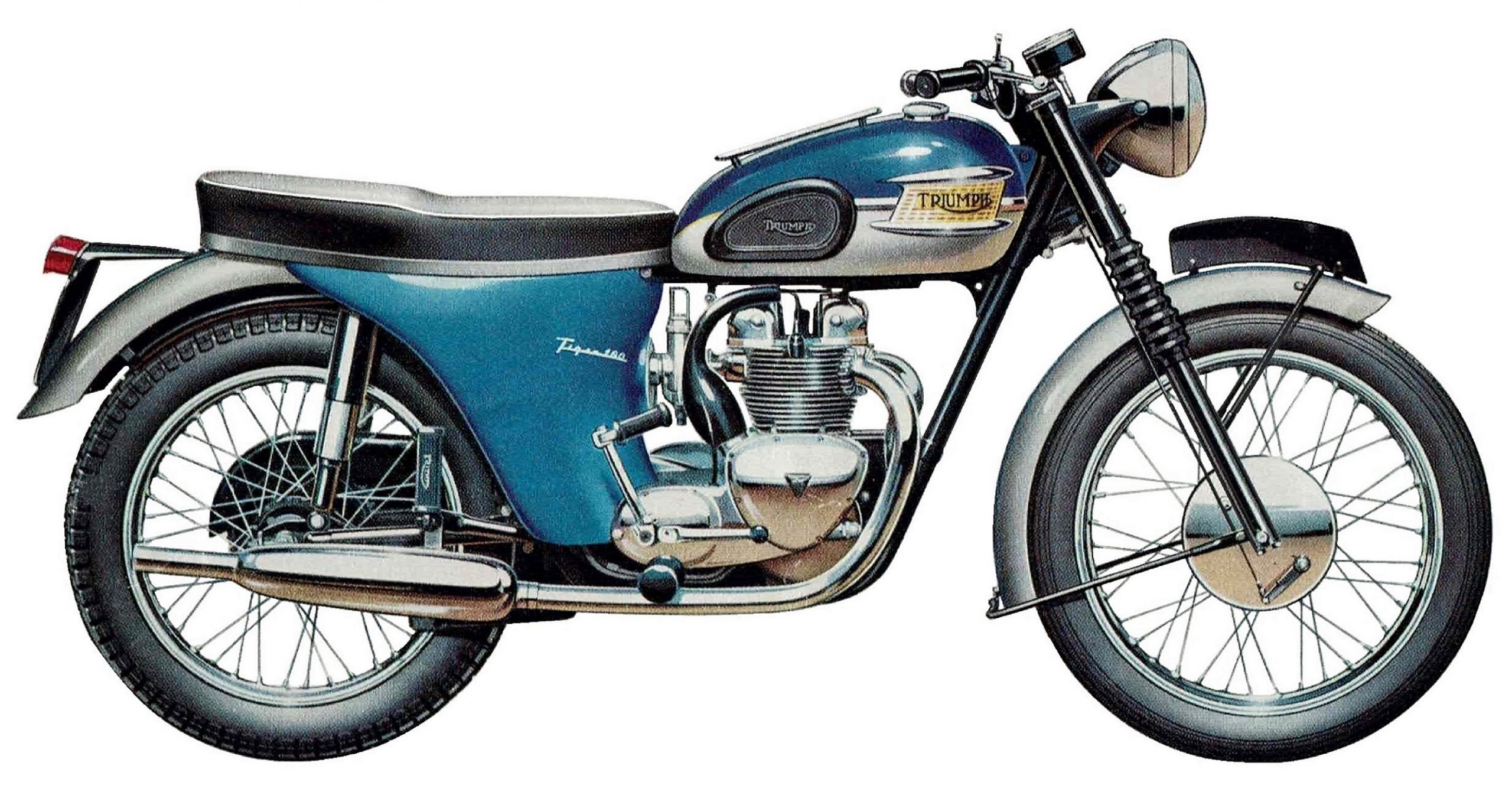

Shown here the 1960 3TA and T100A

1960

Engine Frame Numbers H11512-H18611.

| Models Covered | Standard | Police |

|---|---|---|

| 1960 Triumph 3TA | 2758 | 6 |

| 1960 Triumph 5TA | 2172 | 42 |

| 1960 Triumph T100A | 2120 |

Sales for all Triumph Models for 1960

| 1960 | T20 | T20S | 3TA | 5TA | T100A | T100 | TRW | 6T | TR6 | T110 | T120 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Home | 7416 | 728 | 1697 | 1592 | 1209 | 1383 | 155 | 1581 | 201 | ||

| Jomo | 358 | 720 | 24 | 33 | 122 | 50 | 652 | 122 | 598 | ||

| Tri-Cor | 540 | 582 | 30 | 77 | 114 | 171 | 638 | 274 | 878 | ||

| Export | 2135 | 169 | 988 | 544 | 327 | 12 | 198 | 601 | 274 | 375 | 479 |

| 10449 | 2199 | 2739 | 2246 | 1772 | 12 | 198 | 2205 | 1719 | 2352 | 2156 |

The Sales figures above show the popularity of the Cub dwarfing all other models, with larger models becoming popular in the USA.

Note the poor sales of the 3TA and 5TA into the USA but strong sales into the Home Market. Most surviving machines are UK machines.

For 1960 the 5TA (not illustrated) remains in much the same specification as the previous year apart from the general changes introduced during production.

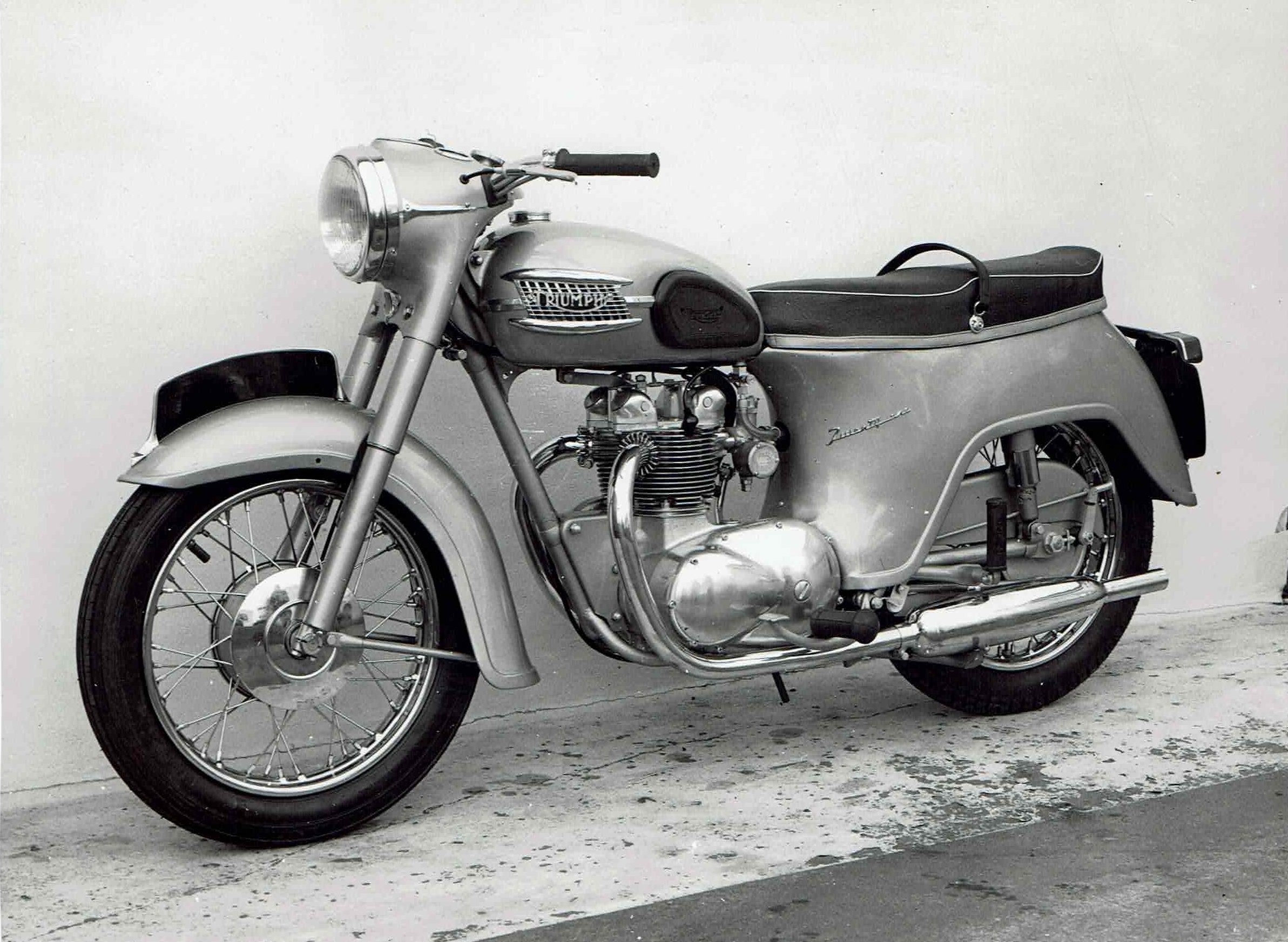

Factory Portrait Photographs were taken outside in a small area behind the canteen that had been prepared, at times such as in this photograph the reflections of the distant background is visible in the timing cover and bathtub. These “Factory” photographs are quite distinctive and can be picked out from most others by the background, they often feature mock up, pre-production machines or test machines that do not represent actual production models and should be considered carefully by restorers.

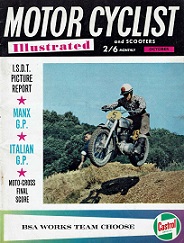

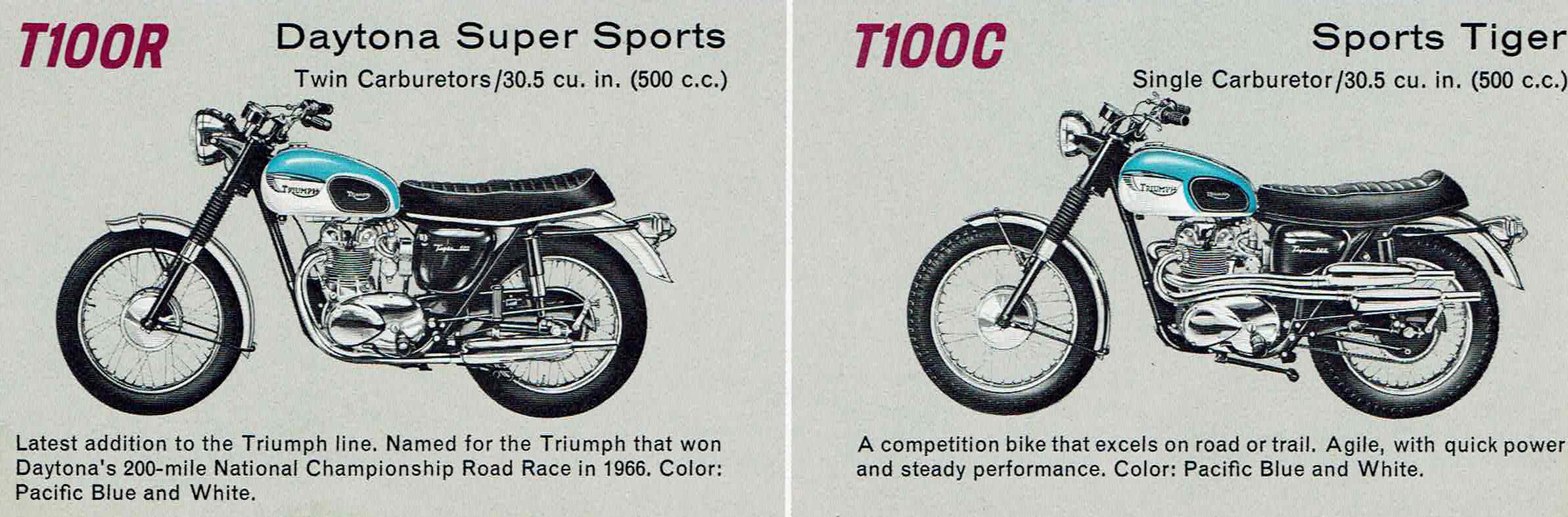

1960 Sees the introduction of the T100A which replaces the successful pre-unit T100, like the 5TA earlier it uses many parts common to the range but is improved by using 9:1 Pistons and sports camshafts giving 32 b.h.p at 7000 r.p.m. The Cylinder Head, Carb and the gear ratios remain as for the 5TA.

Another innovation is the use of energy transfer ignition allowing a battery and rectifier to be dispensed with though both are retained to provide current to the lights.

It needs to be considered that the Pre-Unit Tiger 100 that this model replaces is a sporting model and was often modified for racing and off road use.

Potential owners should not dismiss the T100A, it is a fine machine with excellent performance in a small package, very few survive in original condition and the model sharing many parts with its siblings is easy to maintain but with a distinct performance advantage for modern road conditions.

The 3TA and 5TA share the E3858/E3839 Camshafts but for the T100A E4022/E4023 camshafts are fitted. The Tappets are common across the range.

The alternator on the T100A is not keyed to the crankshaft but is driven by a dowel on the face of the engine sprocket engaging with one of two marked sockets on the rear of the rotor. For normal use the driving dowel engages with the socket marked S but for racing purposes the R socket can be used to advance the ignition timing.

Distributor part numbers for the models are ….

3TA 40573

5TA 40646

T100A 40710 40710B after H17466

The T100A features the Lucas 2ET Ignition Coil while the 3TA and 5TA continue with the Lucas MA6 ignition coil.

Police Machines supplied with the High Output Alternator have additional wiring and a switch to enable the higher charge rate to be enabled at any time.

Alternative Lucas Parts are provided on these machines. Often with these machines the Engine Number will have a W after the number.

The T100A though sharing the same gearbox components as the other models does feature new clutch components to allow two more plates to be fitted. Though complete Clutches are interchangeable be aware that the Clutch components are not!

The 1960 Parts book shows the 5TA and T100A now fitted with the Primary Chain Tensioner this consists of a spring steel blade which can be adjusted to bear upon the chain by access to a screwed sleeve inside the primary drive drain plug. The Chaincase of the 3TA retains the earlier form and so the part numbers differ (E3107-E4122).

During the production year the 3TA is also fitted with the adjuster starting with H18392. See Notes for 1960.

Unlike the 3TA and 5TA which are fitted with silencers incorporating baffles the T100A has less restrictive absorption type silencers (E4157-.8) with removable mutes.

All models now have the QD rear wheel as an option, interestingly most early machines manufactured have this option.

The Nacelle of the 3TA and 5TA remain as for earlier but there is a new Nacelle Top for the T100A to accommodate the smaller Lucas SA41 Lighting switch.

From H13116 the Bathtub Panels change so that the fixing flanges are now external and easier to assemble, a new number plate design is required. I also believe that the support stay seen with the earlier Bathtub is deleted. This stay is not illustrated in the parts book and is only seen in the 1957 3TA press bulletin.

From 1960 all the models have uprated shock absorber springs now at 130 lb, optional springs, of 110 and 145 lb’s are available.

The parts book shows that the 5TA has a different damper unit!

Factory illustrations show that the front Hub Plate has reverted to the plain non fluted style.

Another press illustration shows the presence of a tyre pump located under the Petrol Tank.

American models feature higher bars and appropriate cables.

Colours for 1960

3TA Shell Blue Sheen, Black Frame and ancillary components, Black Hubs; Silver cylinder fins.

5TA Now in Ruby Red overall, Black Cylinder Fins

T100A Black over Ivory separated by Gold lining on the petrol tank, all other cycle parts Black, Black hubs, Silver cylinder fins.

It needs to be noted that machines supplied to overseas governments and Police models will have differing specification.

I urge you to contact the VMCC or the Triumph Owners Club to confirm the original destination of your machine and conduct an internet picture search.

Optional extras include QD Wheels, Pillion Footrests and Prop Stand

Parts book No: 3 Covers machines from H11512

While the earlier parts books are not fully illustrated parts book 3 is and shows the components for each of the models.

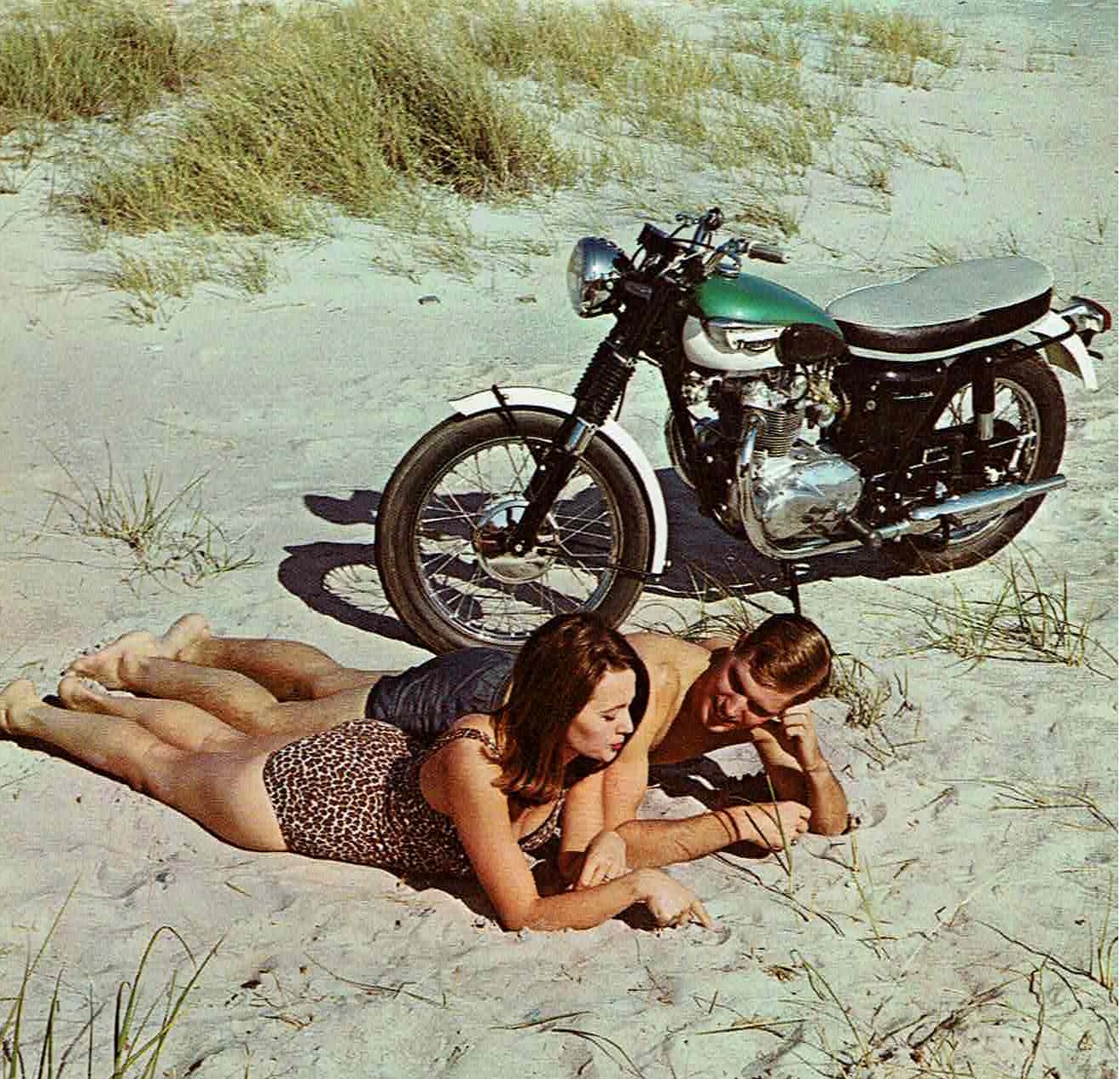

I have several images from this Shoot in my collection, can you name the film?

Notes for 1960

This is a summary of the engine modifications made during 1959 and the models that they apply to/from, these details are taken from the Factory Engine Build Records

H12014 Crankshaft Timing Side Bearing a Locking device is fitted comprising a small plate located by a screw. (Remains until 1967)

H12107 New type engine sprockets fitted, incorporating drillings for an extractor.

H12313 First T100A with primary chain tensioner

H13115 First 5TA with primary chain tensioner

H18392 First 3TA with primary chain tensioner

Police machines become identifiable within the build records as the engines are to a differing specification and recorded as such.

As there is no Earls Court show in 1959 no machines are produced for display but 5TA H12614 is a USA Show Machine.

1960 Production begins on the 1st October 1959 with 3TA’s (H11512-H11545) destined for the USA

H11962 is the first 5TA for 1960 (sent to Uganda)

H12313 is the first production T100A made on the 16th October 1959. Sent to Johnson Motors on the 22nd October.

H12331 is the first UK production T100A sent to Pat Keebles, Leiston.

Most early production of the T100A is for export, you will find them in Borneo, Cyprus, Australia, Venezuela and the USA.

1960 production ends with 3TA H18611 on the 2nd September 1960 this machine is dispatched to Nigeria.

The road test of the T100A featured in “Motorcycling” of March 10th 1960 shows 148 AUE the production prototype T100A (H9480).

The test photos show some interesting details; notably that the rocker covers are on the wrong way round and that the cylinder fins are Black! The article states that the machine is ‘new’ and not run in, I suspect that the engine has been re-conditioned.

A photo of this machine is above, more excellent photographs of this interesting machine survive in the VMCC Collection.

Roy Peplows Trials Tiger 100 built by Henry Vale in the competition shop carries the registration 612 BFD, a Dudley Registration from July 1960, this well known machine is pictured in Don Morleys “Classic British Trials Bikes”

Roy told me that he bought the machine cheaply near his home, second hand and the factory helped to convert it for trials use. It eventually became uncompetitive against the lighter Cubs and later foreign two strokes. As with many competition machines, upgrades were regularly added during its life.

This machine, now numbered H24122 a 1961 model was sold from a collection at the Stafford Auction in April 2019

The Tri-Cor Monthly Hints and Tips Service Department Bulletin for January 1960 indicates that nine T100A machines are entered in the 100 Mile Class “C” amateur race at Daytona Beach (March 7th to 13th) and Six Expert Riders on New Triumphs in the 200 Mile National !

Bob Burnett (T100A) Finishes 4th in the Amateur Race.

These race machines are likely to be from between H13749 to H13840 as this is a group of T100A’s dispatched to the USA in late December 1959.

For more information look for Gregory R Pearsons “The Complete Grand National Championship Volume 1”. This excellent book contains the results for all of the USA National Races from 1954 to 1969 with numerous pictures. A must have book for race fan and researchers.

Triumph Riders to research for 1960 are Bob Burnett Wenham Mass, Ray Durham Greenville SC, Everett Brashear and the soon to be famous Sammy Tanner.

Another rare book to look for is J.J O’Malleys “Daytona Hot Shoe, The History of Short Track Motorcycle Racing in Daytona Beach”

From the September 1960 issue of cycle (below) is an extensive report on the Laconia Road Races attended by 22,000 fans with at least five riders entered on Triumphs. Winner of the 25 mile novice race is John Platchek from Sprinfield PA on a modified T100A, fans will recognise many famous names in the line-up.

Interestingly the article has a picture of a 3TA included.

In “Motorcycle Mechanics” June 1960 is a Road Test and Decoke article on a 1960 3TA (683 AWD)

In 1960 at the Bonneville Salt Flats Danny Macias takes a modified 3TA to a new class ‘C’ speed record of 116.42 mph.

The machine survives and appears in a you tube video at www.youtube.com/watch?v=L699Ry3MvRs

Danny Later becomes Triumph’s Racing Manager and appears in several later period photographs.

Prices as stated in September 1959 for the 1960 season.

3TA £ 227/19s/8d

5TA £ 237/12s/8d

T100A £ 247/17s/9d

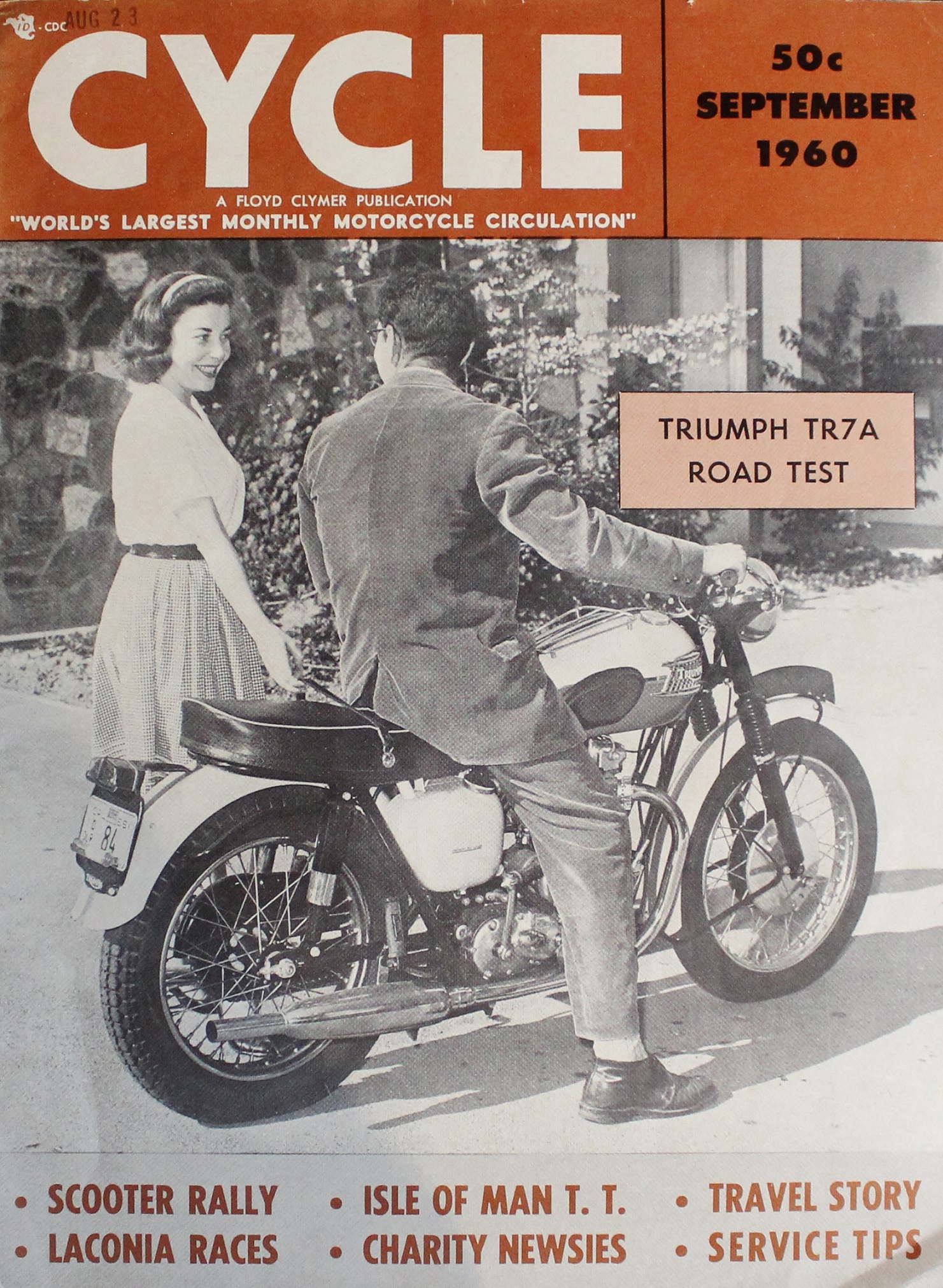

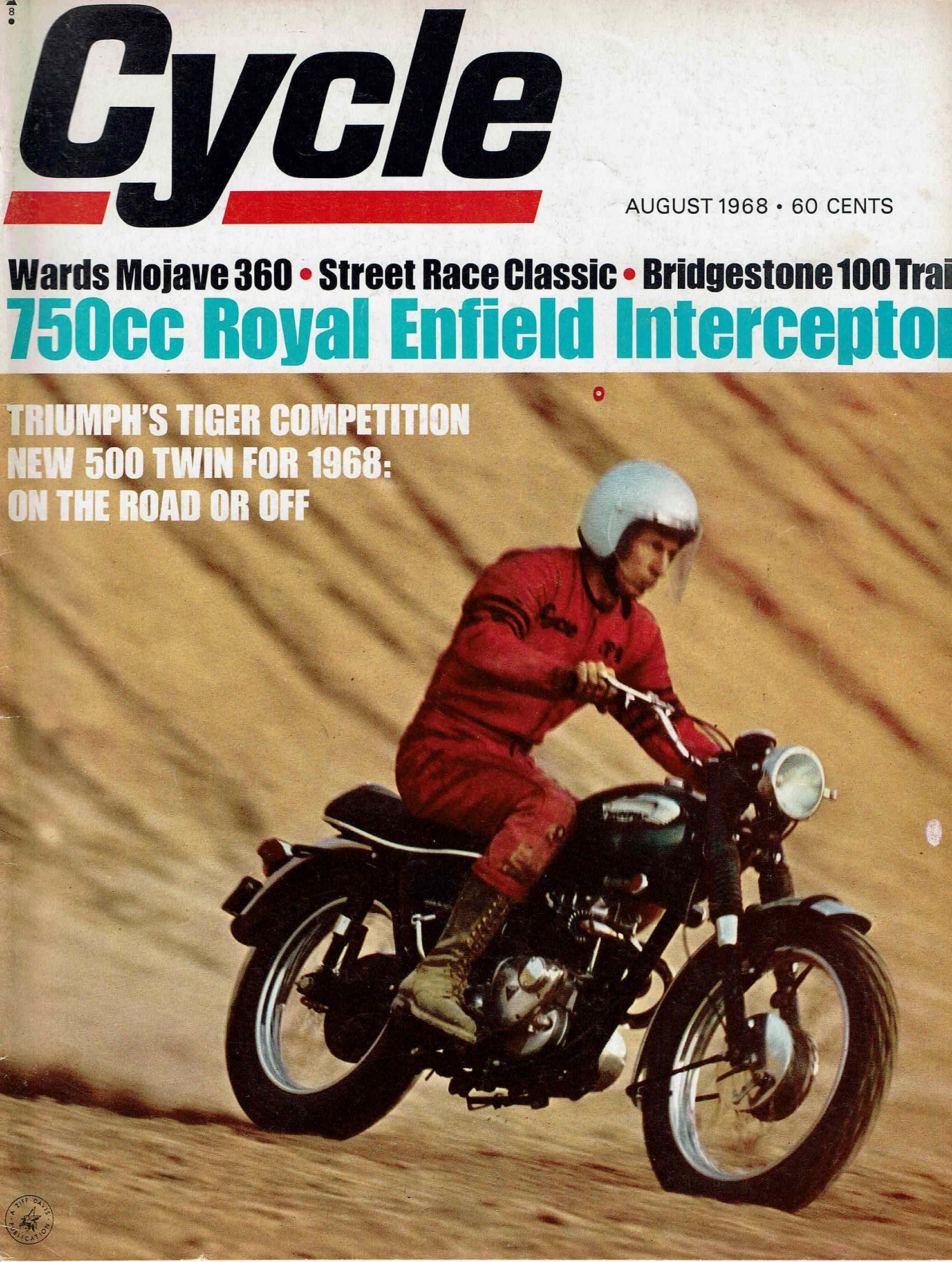

A road test for the 1960 TR7A Bonneville in Cycle Magazine.

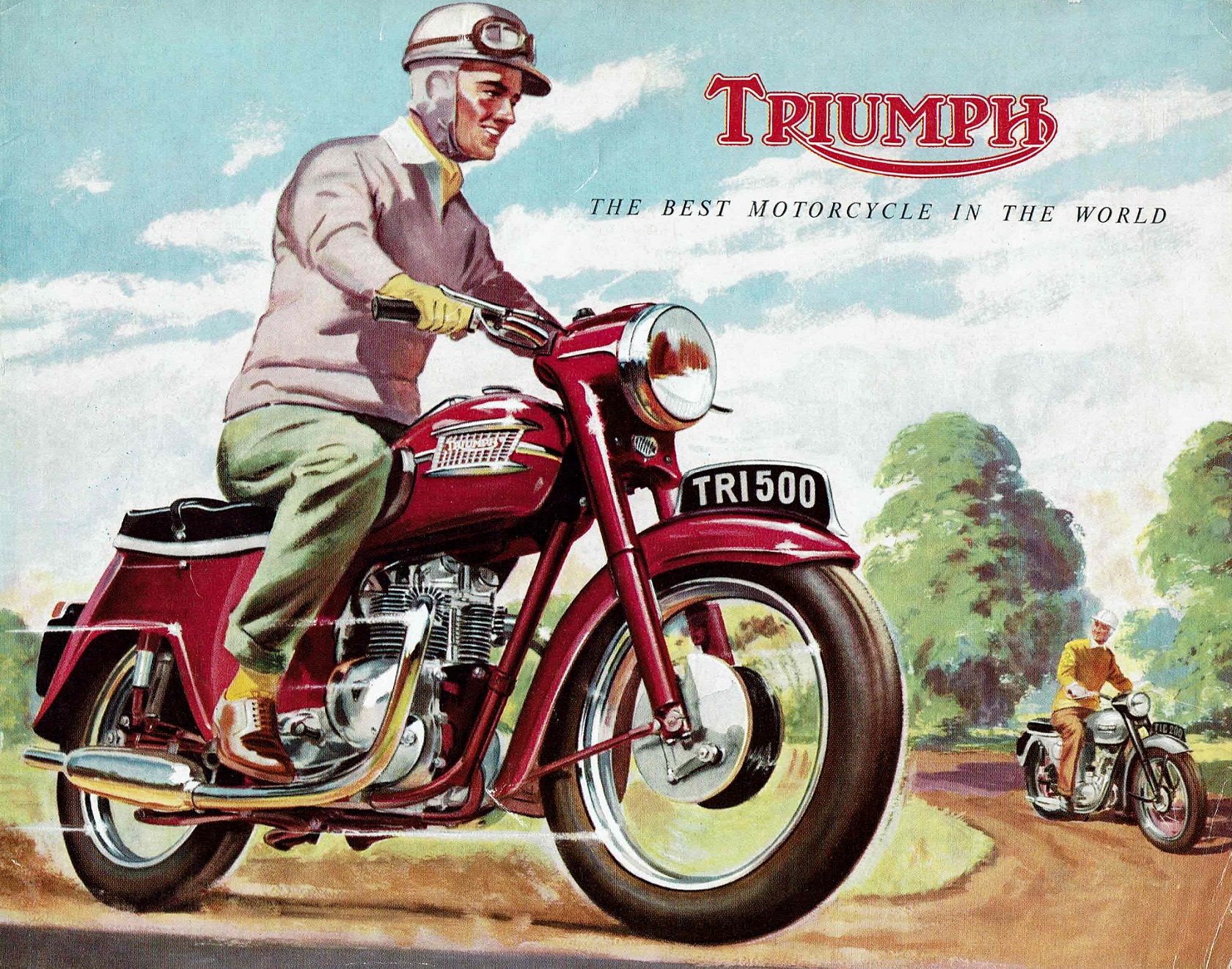

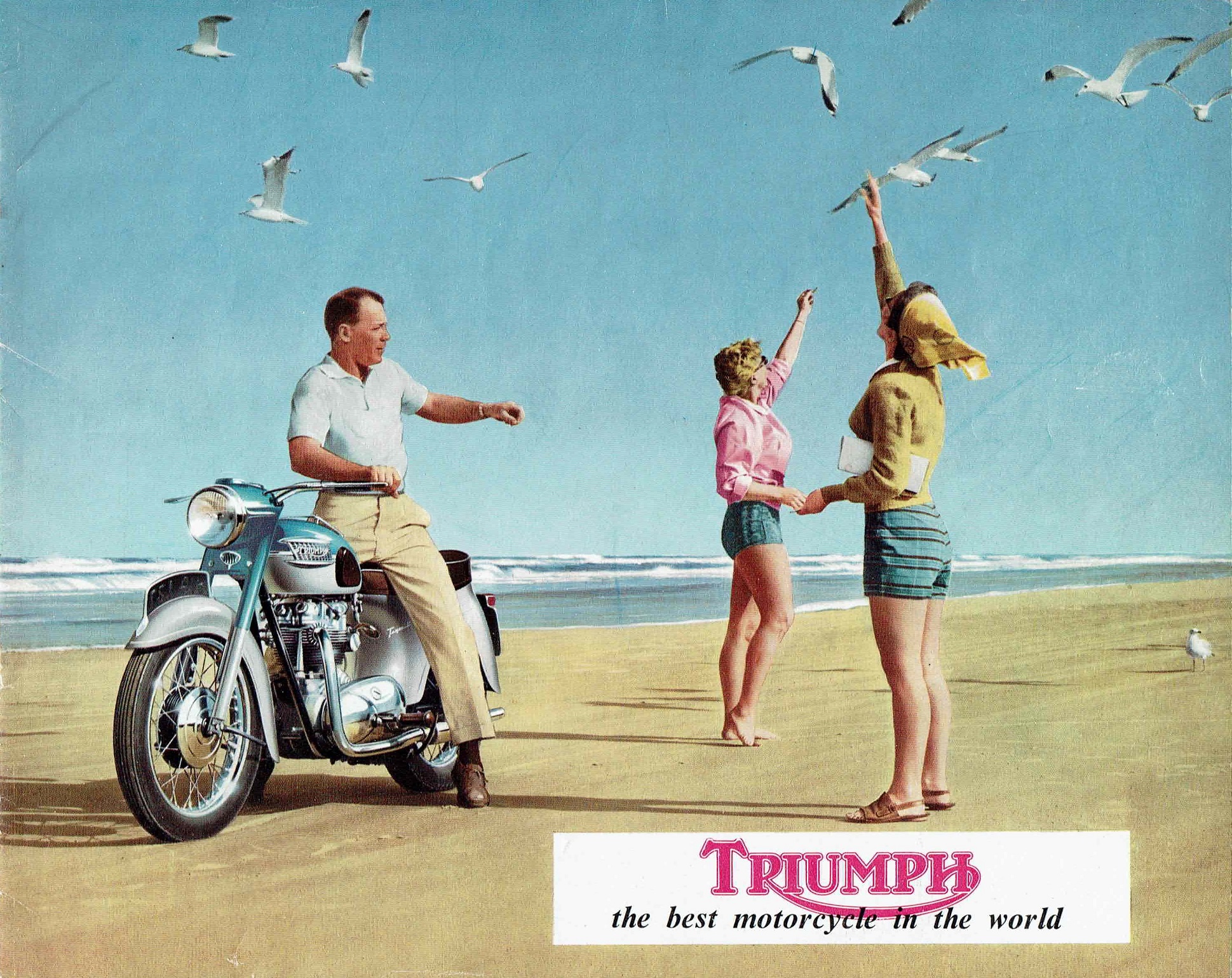

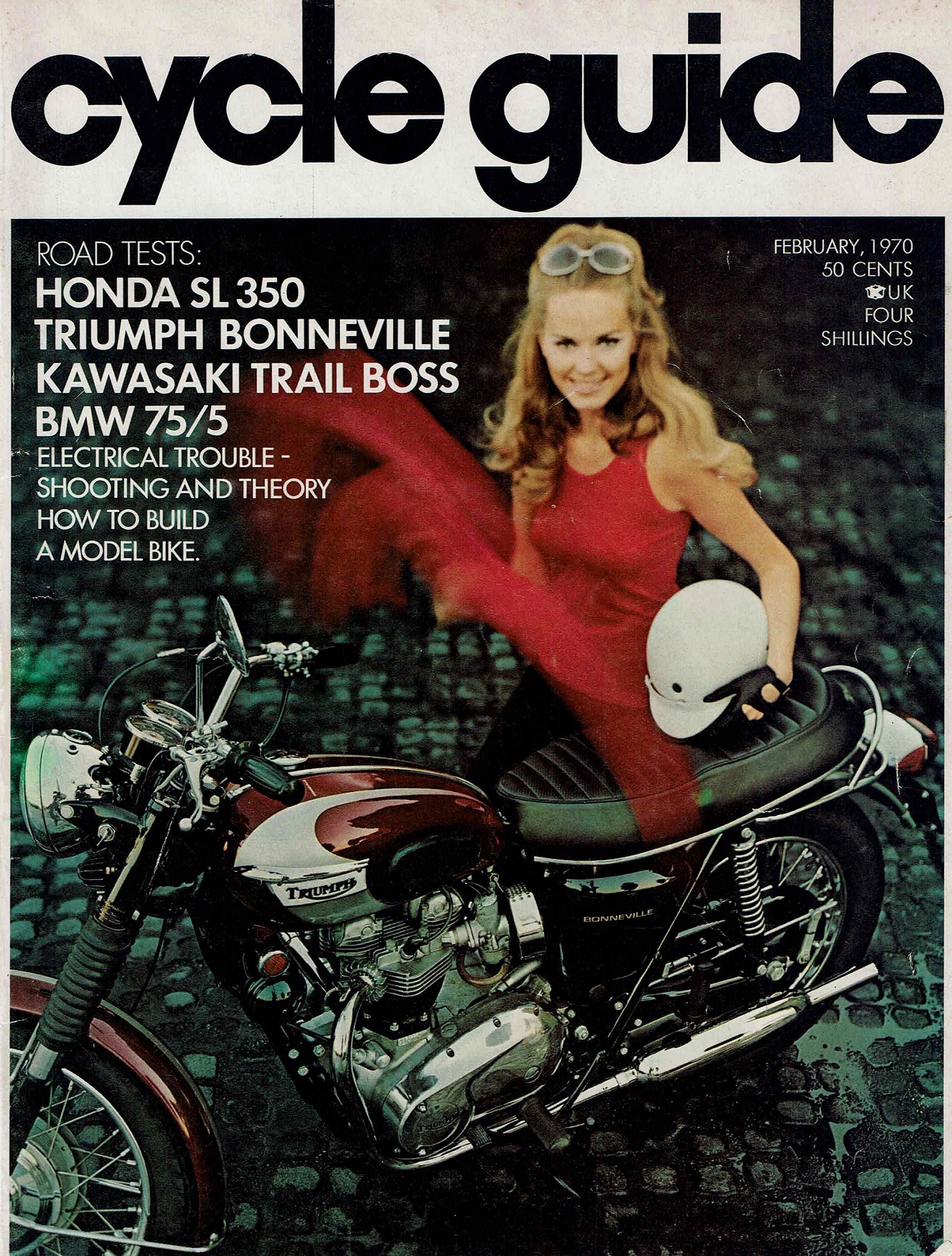

The 1961 Catalogue Cover featuring Walt Fulton a successful Triumph racer.

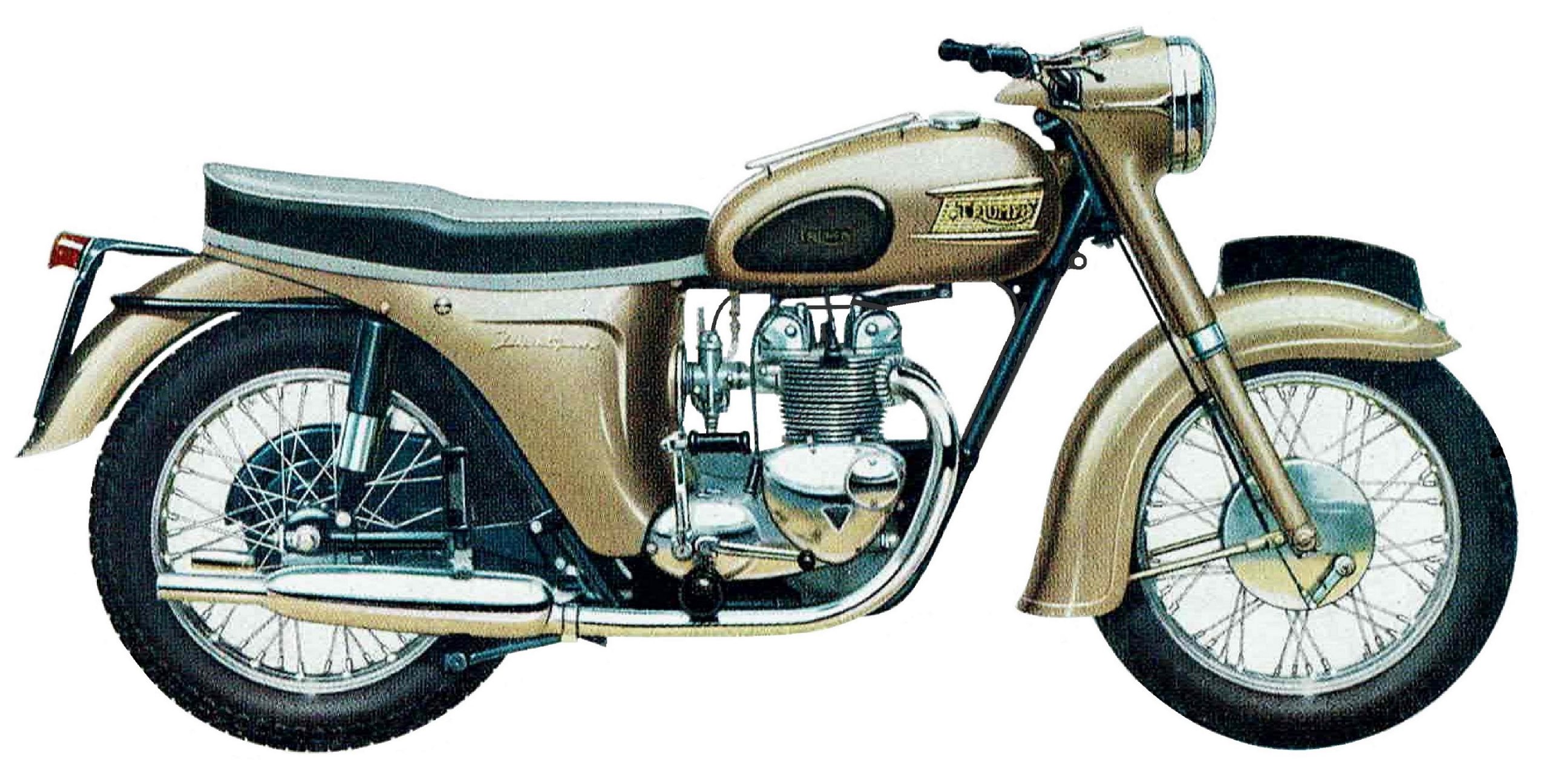

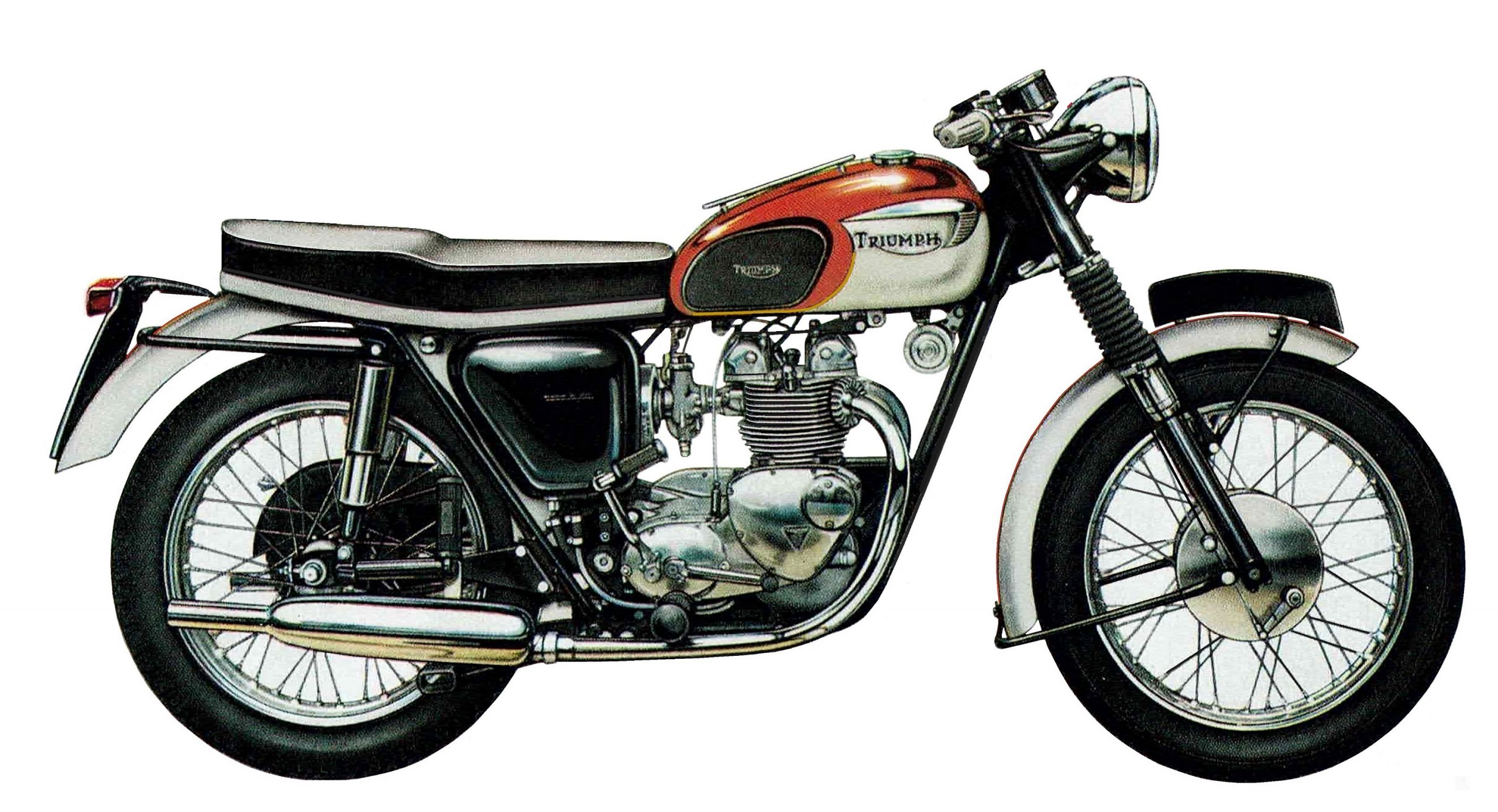

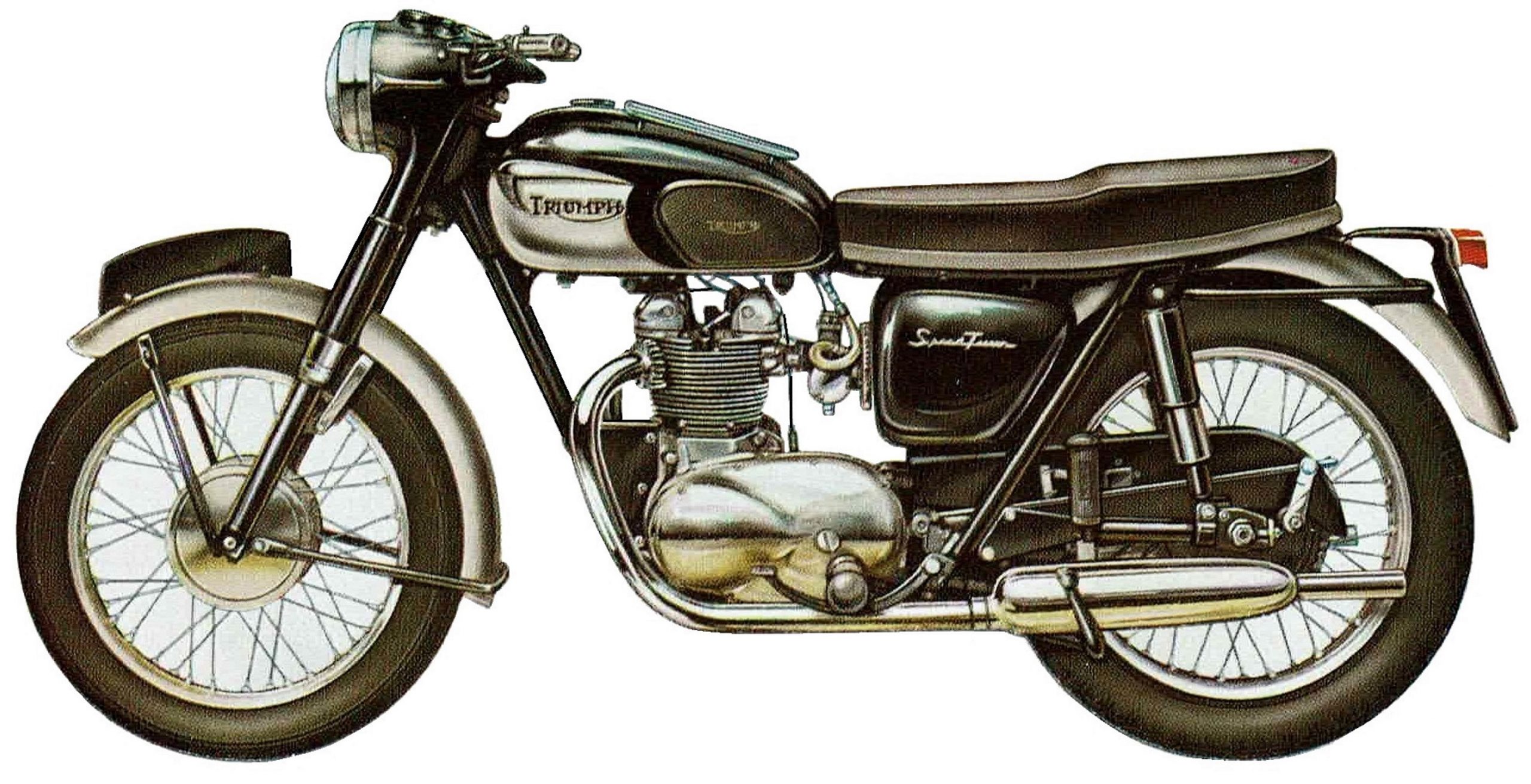

1961 T100A and 5TA .

1961

Engine Frame Numbers H18612-H25251. (H24241)

| Models Covered | Standard | Police |

|---|---|---|

| 1961 Triumph T90 | 1 | |

| 1961 Triumph T100A | 1006 | |

| 1961 Triumph TR5AR | 462 | |

| 1961 Triumph TR5AC | 669 | |

| 1961 Triumph 3TA | 2995 | |

| 1961 Triumph 5TA | 1477 | 18 |

Sales for all Triumph Models for 1961

| 1961 | T20 | T20S | T20T | T20SL | 3TA | 5TA | T100A | TR5AR | TR5AC | 6T | T110 | T120R | T120C | TR6R | TR6C |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Home | 7164 | 1 | 258 | 1262 | 1575 | 1171 | 1013 | 1251 | 1208 | 1326 | 475 | ||||

| Jomo | 56 | 189 | 155 | 193 | 14 | 14 | 12 | 75 | 350 | 22 | 44 | 295 | 139 | 175 | 216 |

| Tri-Cor | 304 | 124 | 150 | 230 | 6 | 32 | 26 | 250 | 255 | 52 | 312 | 530 | 56 | 337 | 75 |

| Export | 2777 | 17 | 43 | 87 | 1401 | 371 | 72 | 135 | 24 | 522 | 322 | 345 | 34 | 123 | 27 |

| 10301 | 331 | 606 | 1772 | 2996 | 1588 | 1123 | 460 | 629 | 1847 | 1886 | 2496 | 229 | 1110 | 318 |

The 1961 Catalogue Cover Artwork shown above originates from a photograph taken earlier showing Walt Fulton on a racing machine with two women feeding seagulls. The composition of the photograph is translated into the artwork above but the machine featured is very different, most triumph artwork until 1967 uses this technique which makes the images of machines used especially accurate.

Sales of the various Cub Models remain strong especially in England, again there is growth in the US Market.

Sales of the 3TA, 5TA and T100A remain poor in the US market but the new sports models show promise.

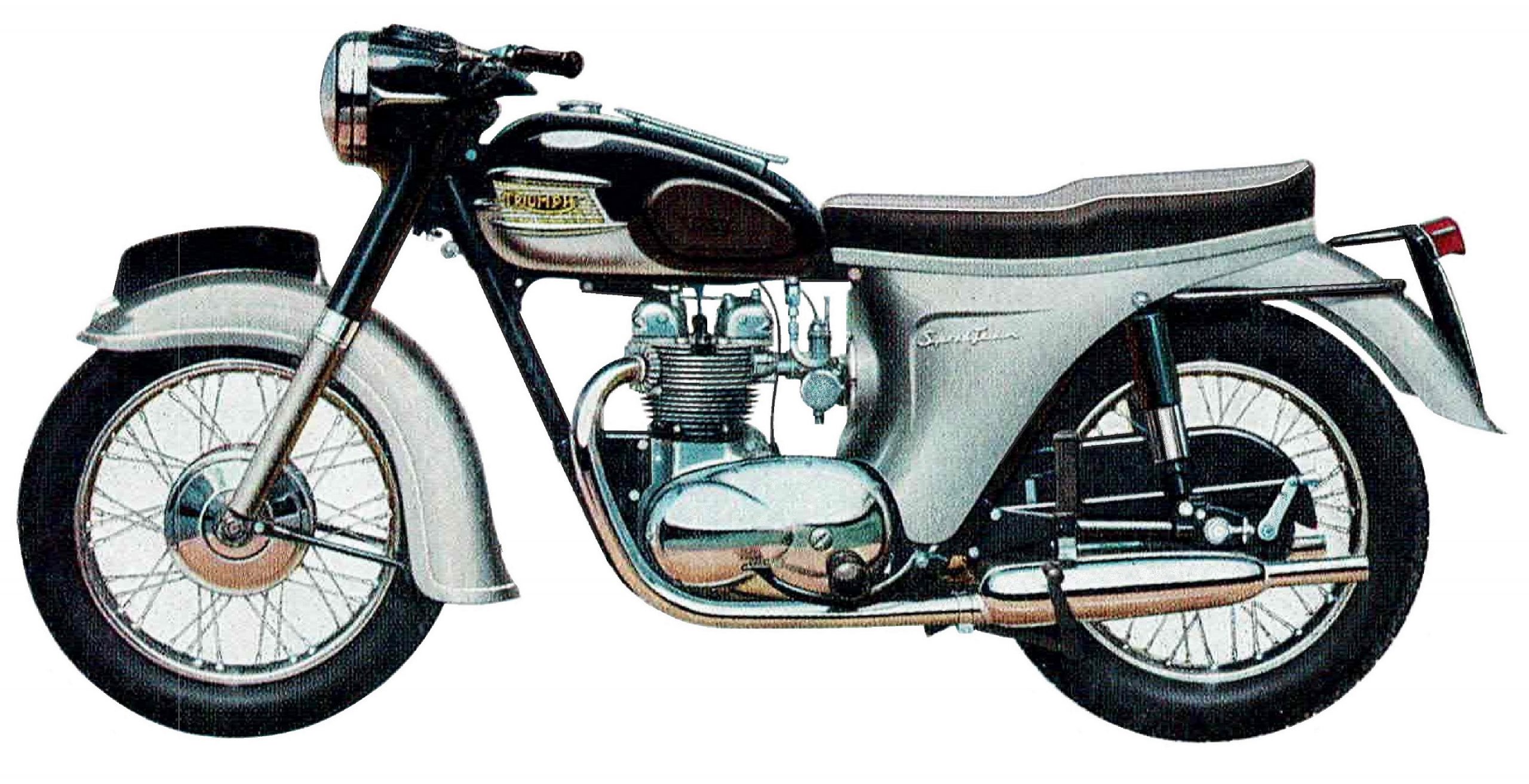

The 1961 Model T100A being attractively displayed at the Earls Court Show, November 1960.

The Factory records show that a number of machines produced after H24241 were converted to 1962 Specification, this includes 73 5TA’s and 177 T100A’s converted to 3TA’s these machines retain the original T100A Frame and Engine numbers although new engines were fitted. If your machine falls within this group it is vital that you consult the factory records held by the VMCC or TOMCC to confirm the model and specification.

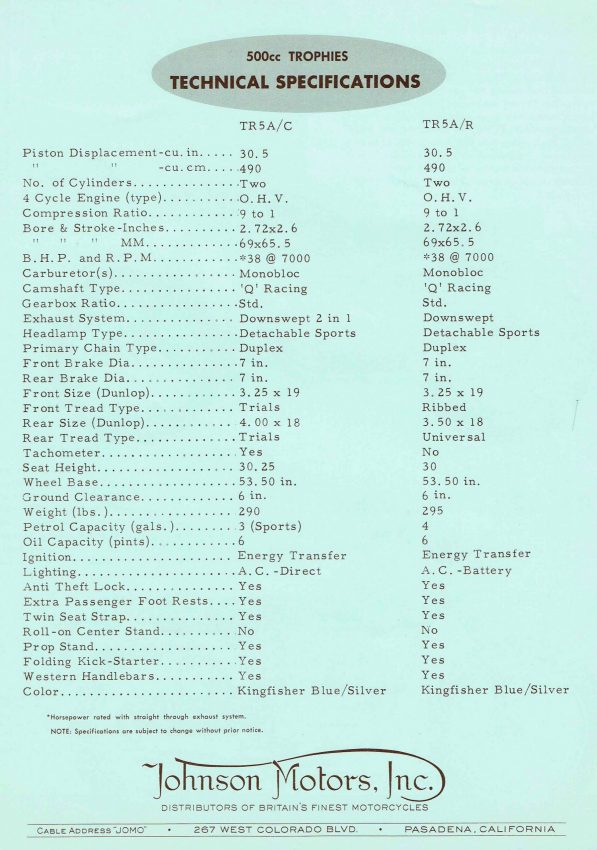

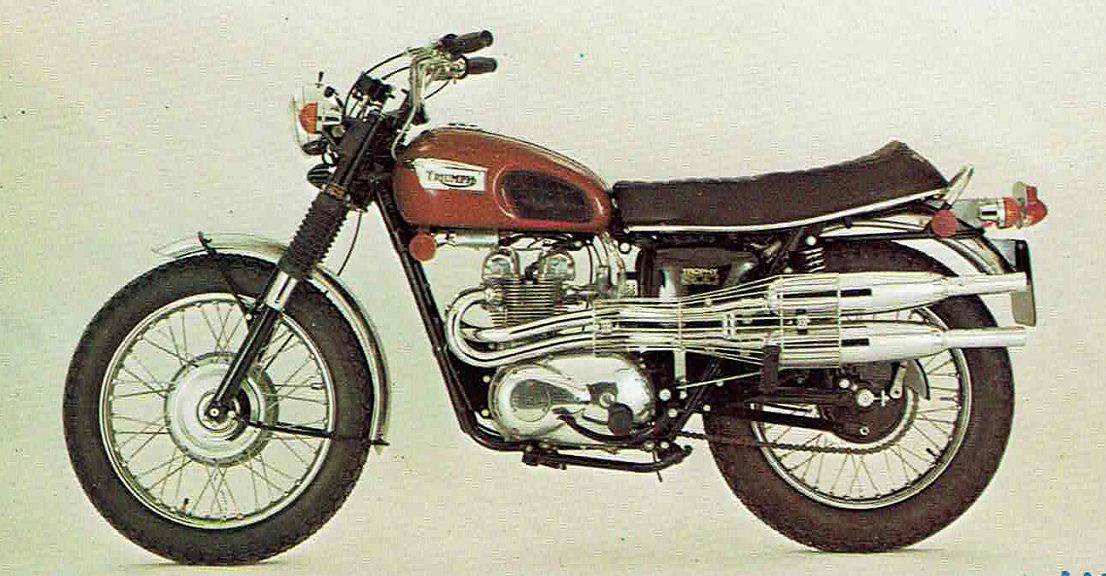

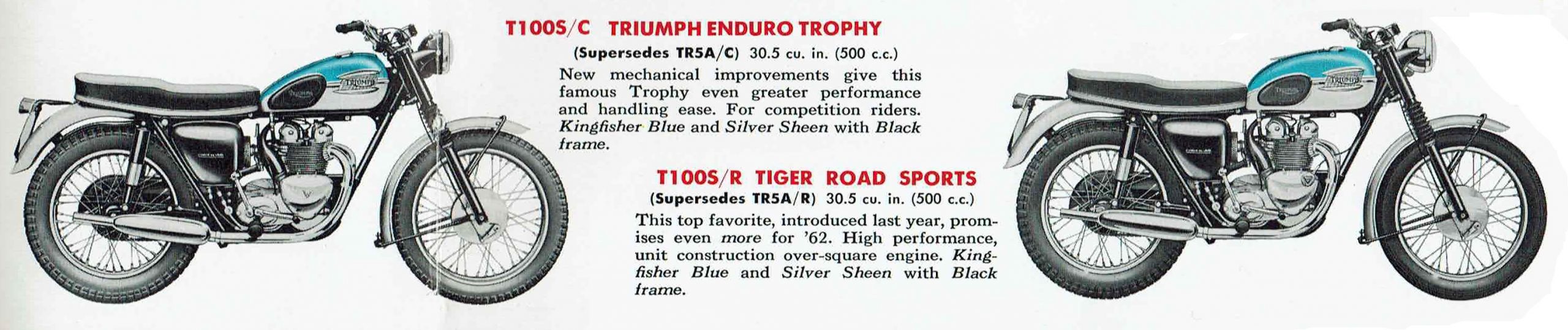

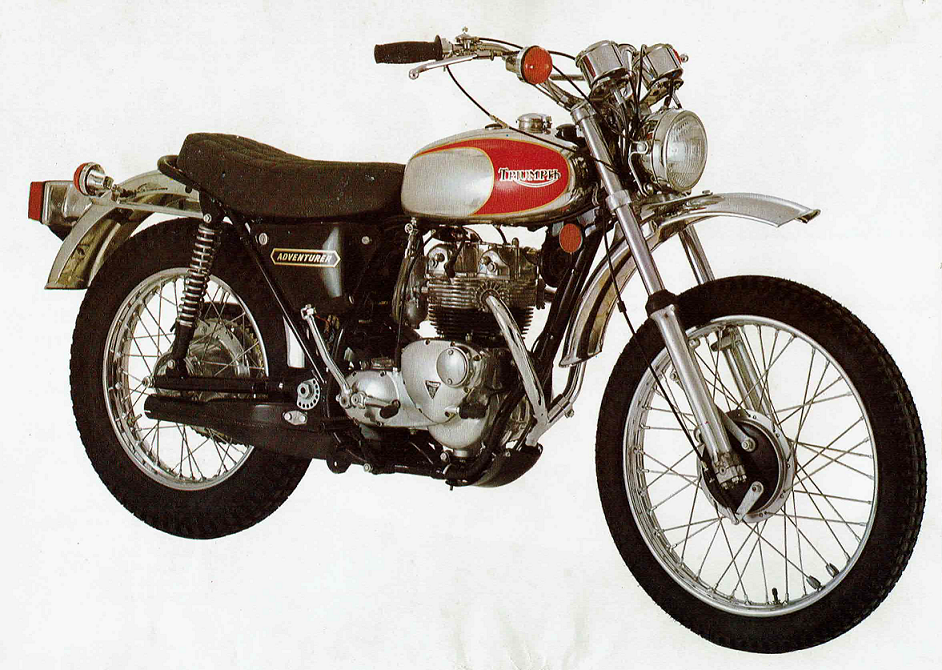

For 1961 the 3TA, 5TA and the Tiger 100A are joined by New Models for Export only, the TR5AC and TR5AR; most of these destined for America.

The TR5AC features a rubber mounted small competition petrol tank, Trials Universal Tyres 3.25-19 Front 4.00-18 Rear, Wide ratio Gears, Direct lighting, Energy Transfer Ignition without battery, detachable headlamp and Siamesed exhaust system terminating into a slightly upswept silencer.

On early batch machines the small Tank is held in place by a rubber band strap which is later replaced by the four Shouldered Bolts and Rubber Bushes seen on all later tanks.

See Below for more details.

To Confirm the Specification refer to the Supplement to the Parts Book No:4 as this details the sports models which have four versions for 1961-62